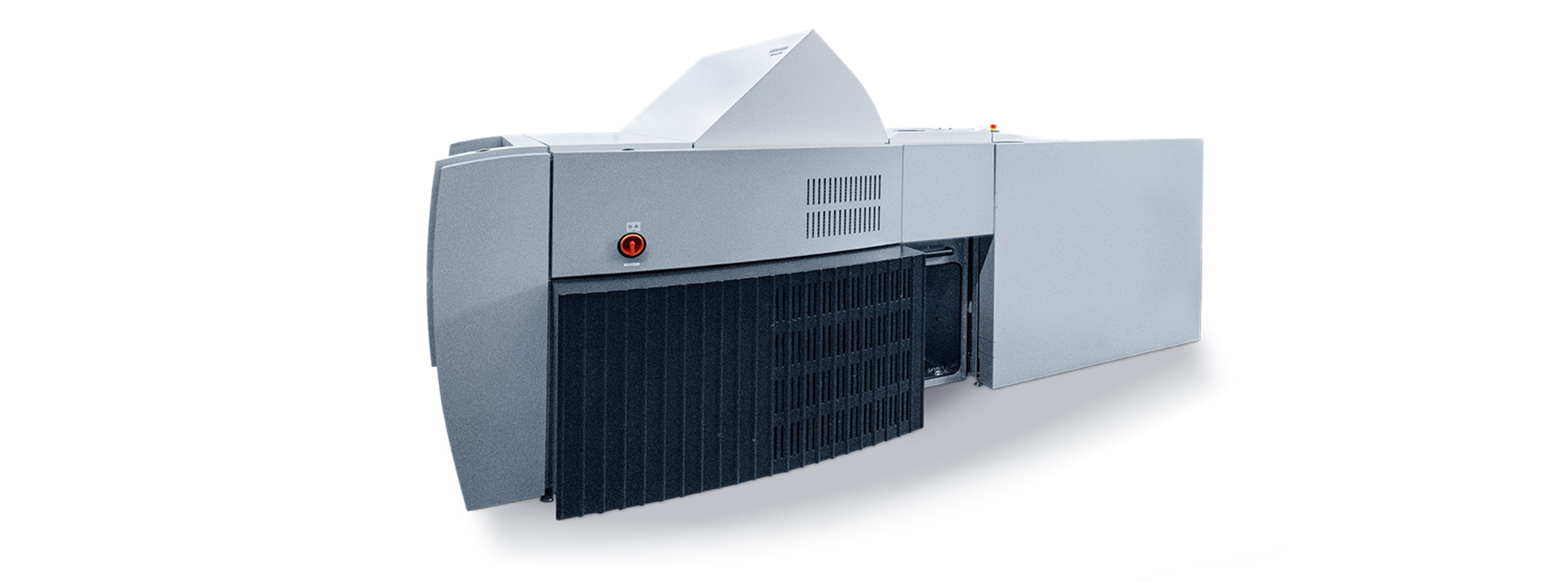

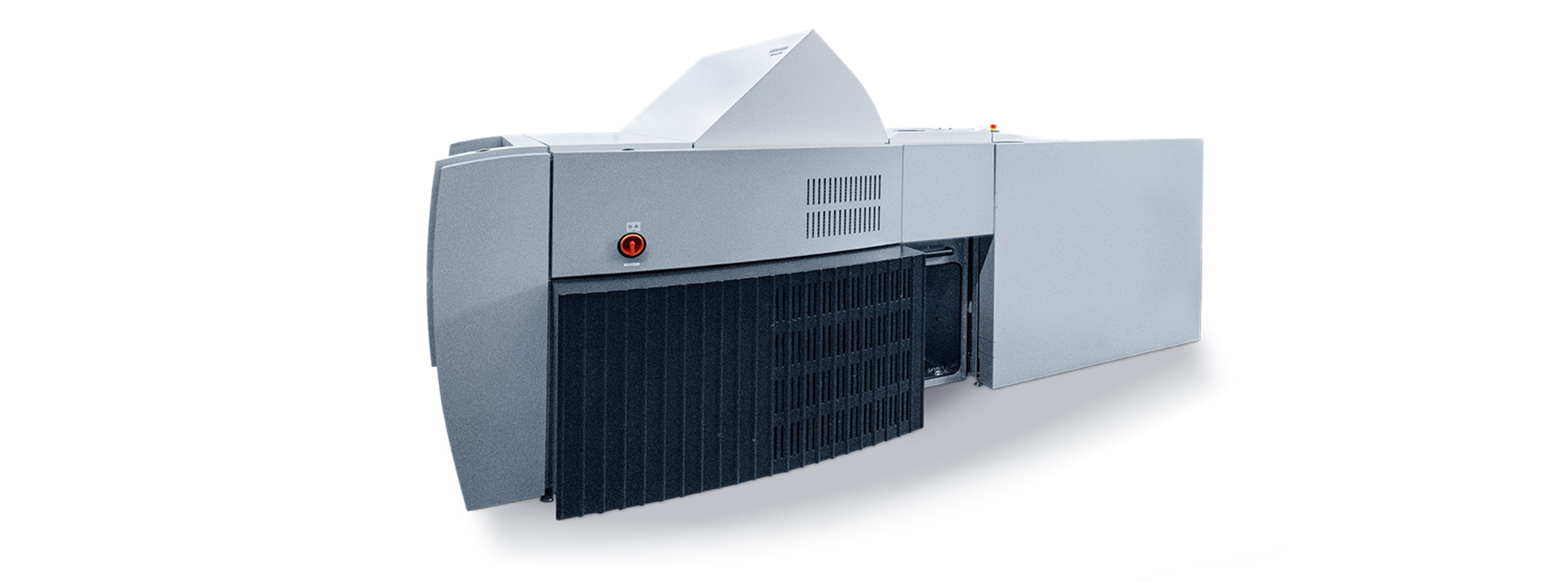

Whilst the basic manual feed CtP has a very small footprint, a Suprasetter A75 with auto plate loading system is by far the smallest platesetter in its class. This makes it an ideal time to invest in computer-to-plate technology without having to make major changes to your prepress workflow.

The modular Suprasetter A106/106 offers maximum flexibility for format classes up to 106. Its intelligent diode system (IDS) provides virtually complete protection against production downtime. The integrated cooling system prevents fluctuating external temperature influences and stabilizes production quality.

Manual loading carries a risk of scratches and errors on printing plates, which is reduced or prevented by automatic loading. Plate loading automation also reduces staffing requirements during late and night shifts. Depending on the number and use of plate formats, there are different storage requirements, which Suprasetter Automation can meet.

| Suprasetter A 75 | Suprasetter A106 | Suprasetter 106 | |

| Automation | DTL | DCL, CPL, APL | DCL, CPL, APL |

| Extraction and dust filter system | ✓ | ✓ | ✓ |

| Temperature stabilizer | - | - | ✓ |

| Intelligent Diode System (IDS) | ✓ | ✓ | ✓ |

| Inline punching | ✓ | ✓ | ✓ |

| Security printing for 5080 dpi | option | option | option |