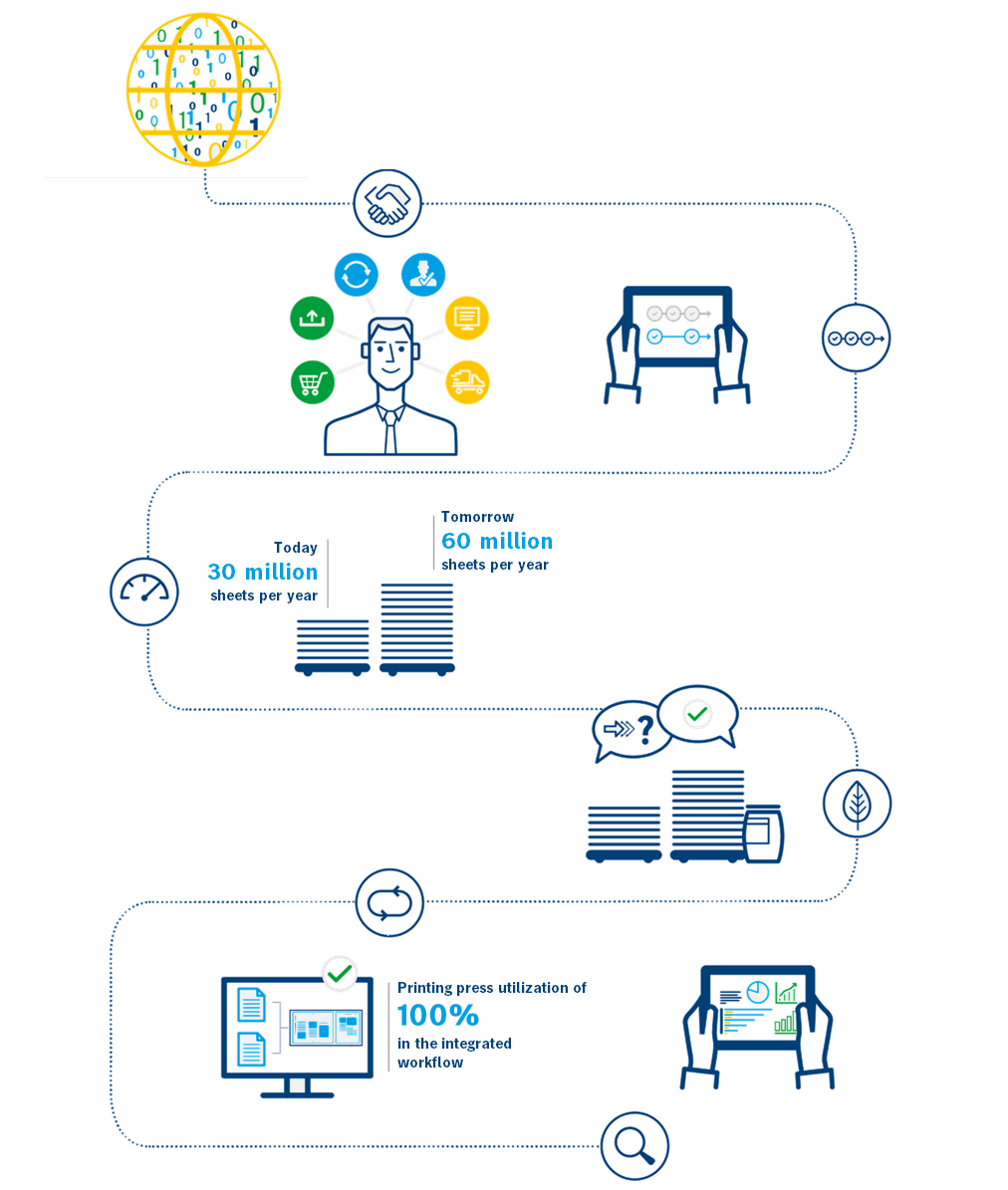

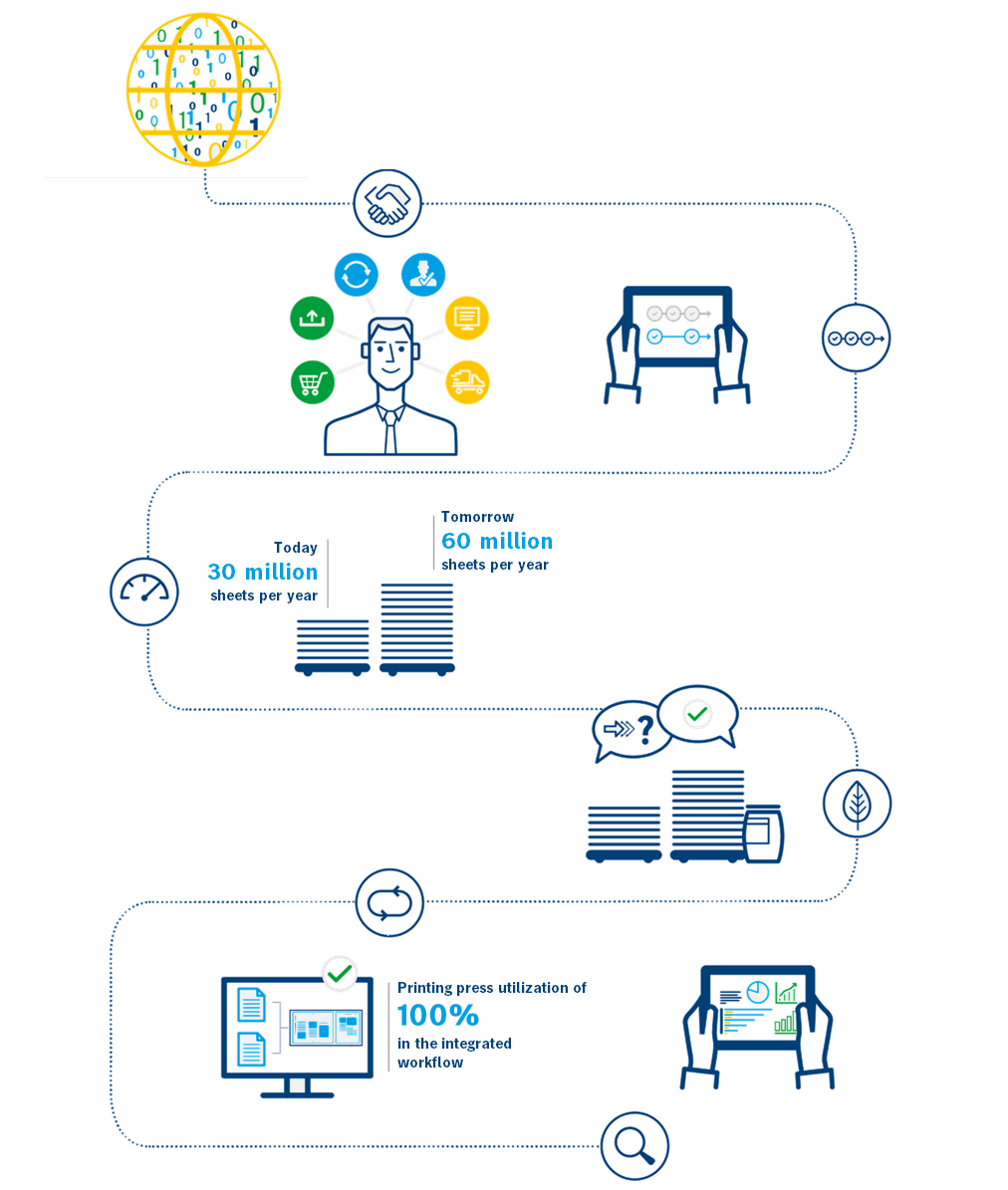

“A printing press is made to print.” In practice, however, only 30 % of its potential is exploited on average*. One reason for this is that the areas upstream of the actual printing process are working at their capacity limit. The crucial factor: these areas account for 55 % of the throughput time of a print job*. The solution to this lies in intelligent machines that organize and process standardized printing processes autonomously. The prerequisite: the harmonious interaction of six key factors.

Integrate customers.

Web portals simplify communication and automate workflows. The result: more efficiency, more customer service, more turnover.

Reduce touchpoints.

Fewer touchpoints and more automation unleash unrealized potential. Throughput increases.

Increase productivity and operating time.

Efficient planning and automatic data availability increase the operating time and productivity. Profits increase.

Reduce paper waste and warehousing.

Optimal materials ensure reproducible production. The paper waste decreases.

Optimize consistency and reproducibility.

Standardization provides certainty and consistency. Production is more predictable.

Business Intelligence.

Business Intelligence delivers sound information. For decision-making based on real facts.

*HEIDELBERG Research.

Are isolated printing processes holding back the full potential of commercial and packaging printing? While many processes have already been digitized, integrating disparate solutions remains a challenge. Find out how Prinect is revolutionizing the industry with seamless end-to-end solutions.