The inking unit of the Speedmaster XL 75 Anicolor consists of a single-speed screen roller with ink chamber blade. The ink is transferred from the screen roller to the printing plate by an ink form roller. The ink density can be quickly changed and adapted to a wide range of substrates and spot colors by adapting the temperature and activating the Anicolor booster.

Economical even with short production runs

Even short production runs can be economically produced with the Speedmaster XL 75 Anicolor. The fast and constant inking means that print jobs are ready for production after just a few sheets. With longer runs, you benefit from the advantages of the offset technology.

One of the main areas of application of Anicolor is commercial printing , where the Anicolor technology provides the optimal solution for fast and economical printing of very short and medium runs.

In label and packaging printing (e.g. in the pharmaceutical or cosmetic industry), Anicolor opens up huge savings potential for short production runs. Spot colors can be changed extremely quickly or replaced by means of the Multicolor workflow.

To find your optimal configuration, please contact your local HEIDELBERG sales representative.

Technical data can vary according to job, consumables, printing stock and, possible, other factors.

What makes the HEIDELBERG-Canon partnership announced at drupa 2024 a game-changer for print shops? Dr. Frank Schaum explains how the new Jetfire fills a gap and how HEIDELBERG is revolutionizing hybrid printing with zero-touch automation, AI and advanced color management.

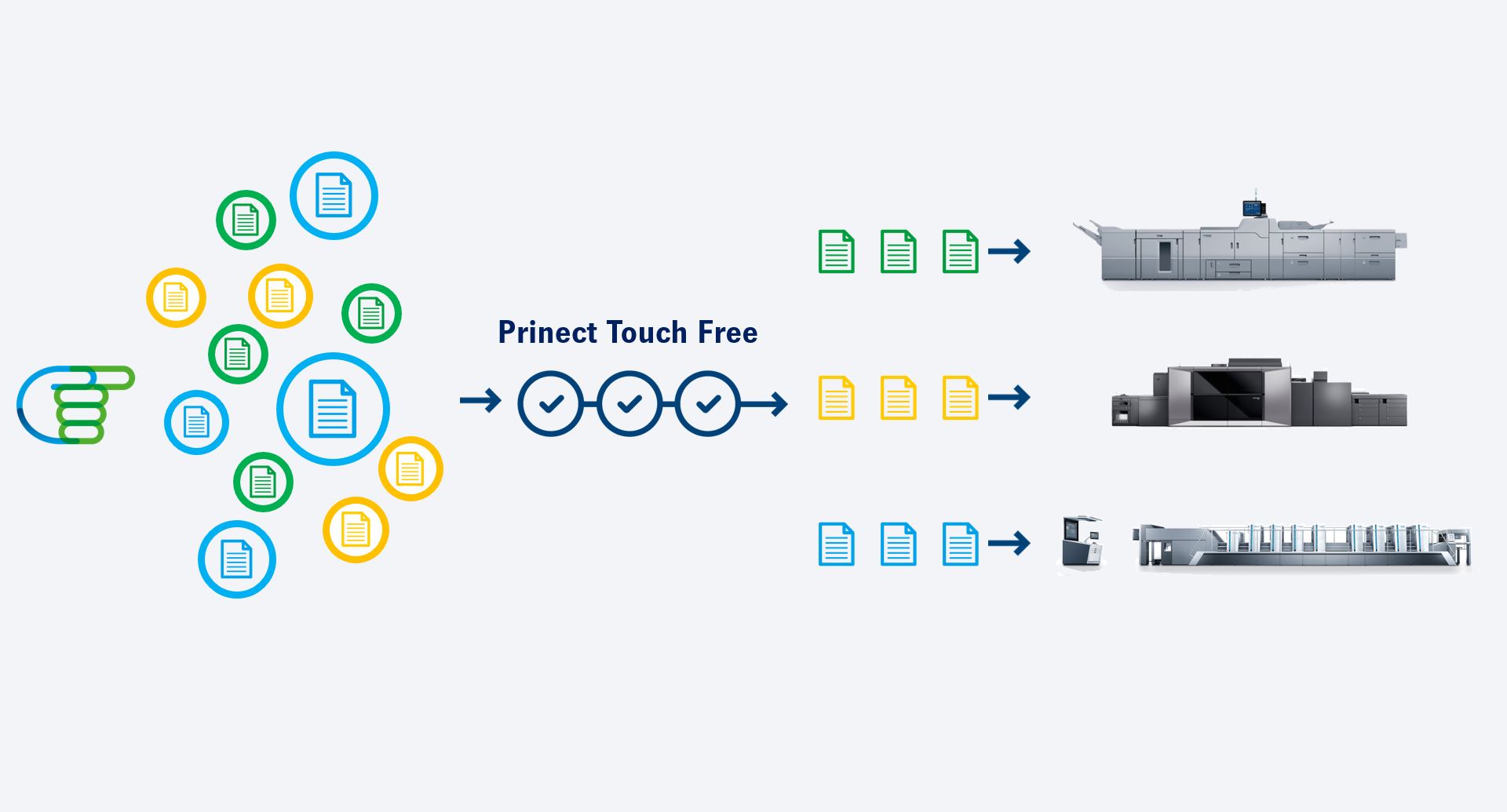

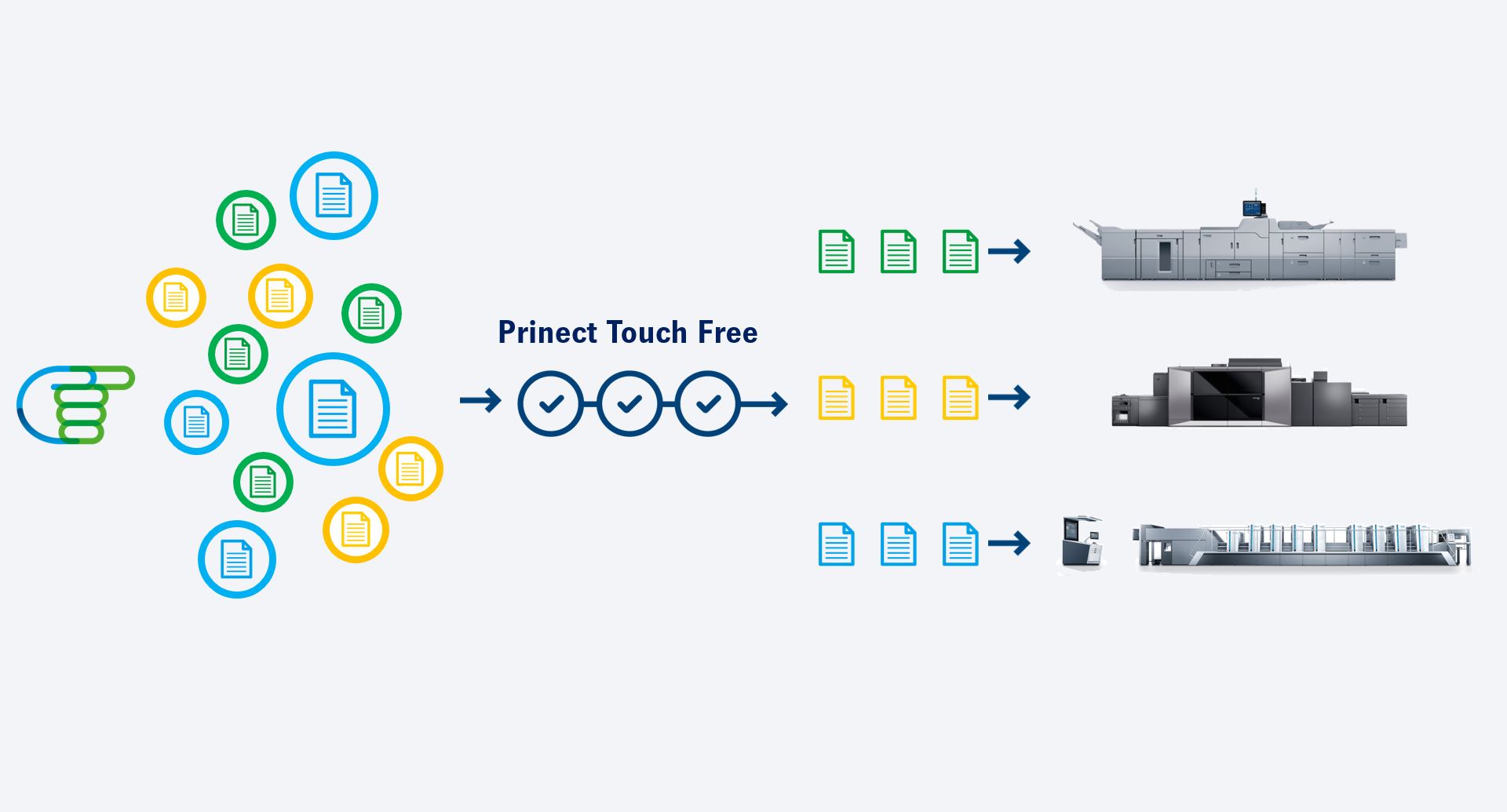

Prinect Touch Free is an option of the Production Manager that seamlessly integrates offset and digital printing into a single workflow. With the help of AI, production decisions will be made fully automatically and precisely in the future. This central control system optimizes your production process, from PDF to finished product. Optimization takes into account the entire order book in three stages, and constantly adapts to changes to ensure the most efficient production method at all times.