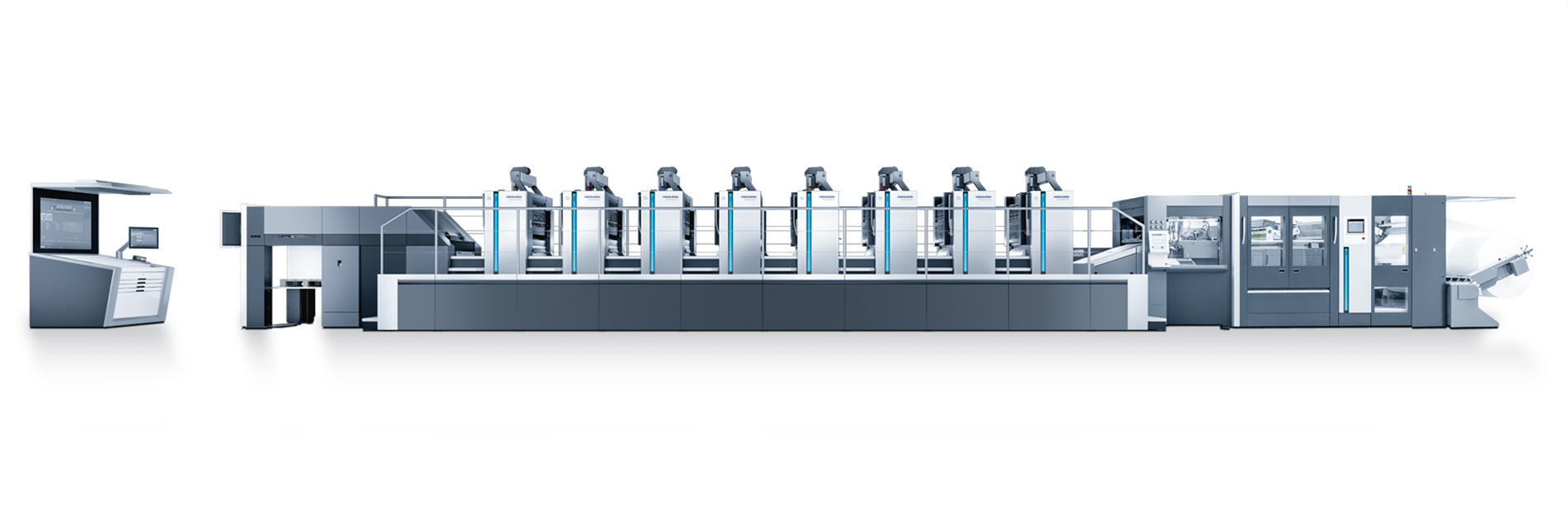

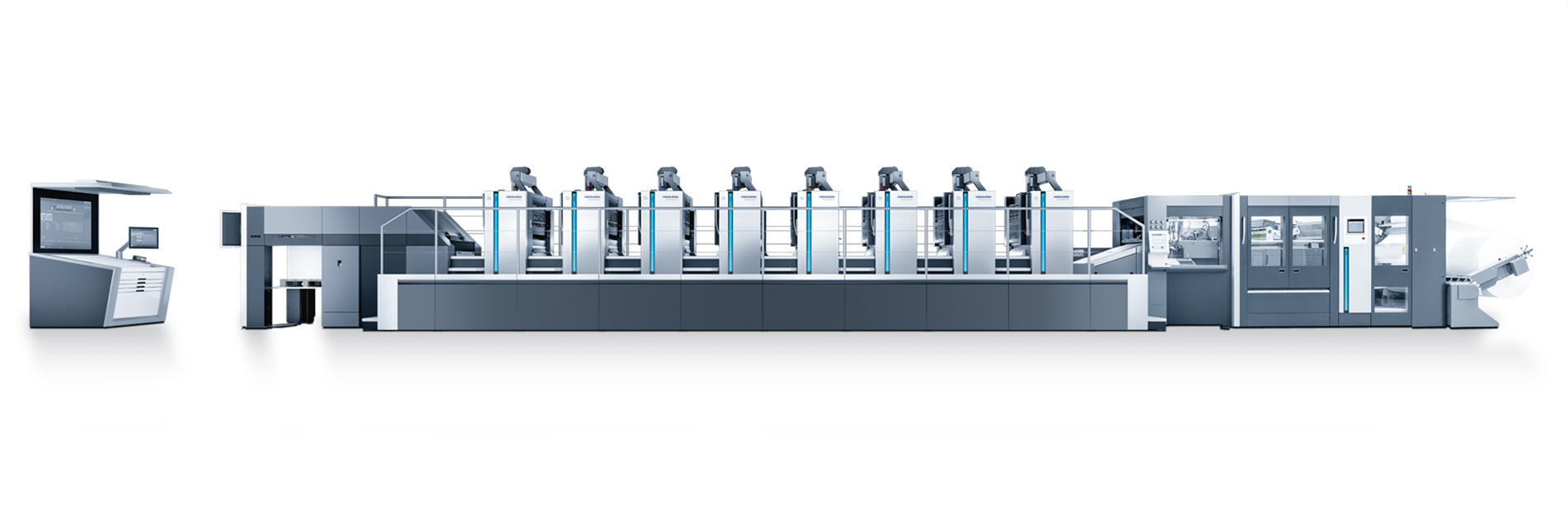

Designed to meet your business needs – the scalability of the Speedmaster SX 102 starts with a well-equipped machine and navigated printing leading up to the Push to Stop functionality

You can choose between two sheet size options: 720 × 1,020 mm (28.3 × 40.2 inches) or 650 × 940 mm (25.6 × 37 inches) which allows you to save up to 20percent of plate costs. Choose the format that best suits your portfolio.

Maximum sheet format 720 × 1,020 mm (28.3 x 40.2 inches) or 650 × 940 mm (25.6 x 37 inches), for reduced plate costs

thanks to visualization of the status of the printing, coating, and drying units

with AutoPlate Pro compared to AutoPlate

from the last to the first good sheet, fully automated job changeover - the ultimate solution

by using roll-fed stock (7 % cheaper) in combination with CutStar

thanks to the innovative, process-oriented operator guidance Intellistart 3

The Speedmaster SX 102 is the perfect choice for your commercial business.

To find your optimal configuration, please contact your

local HEIDELBERG sales representative.