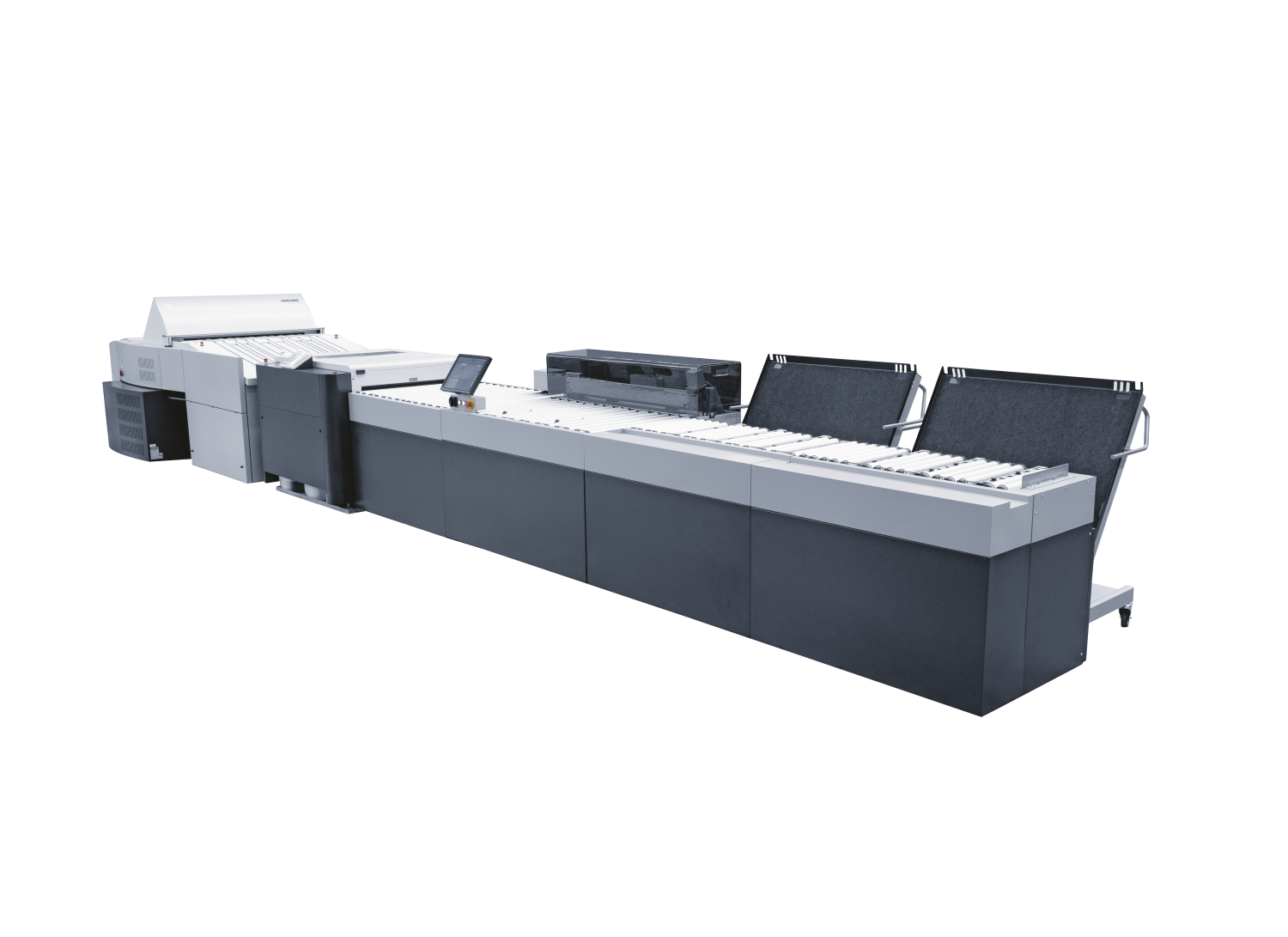

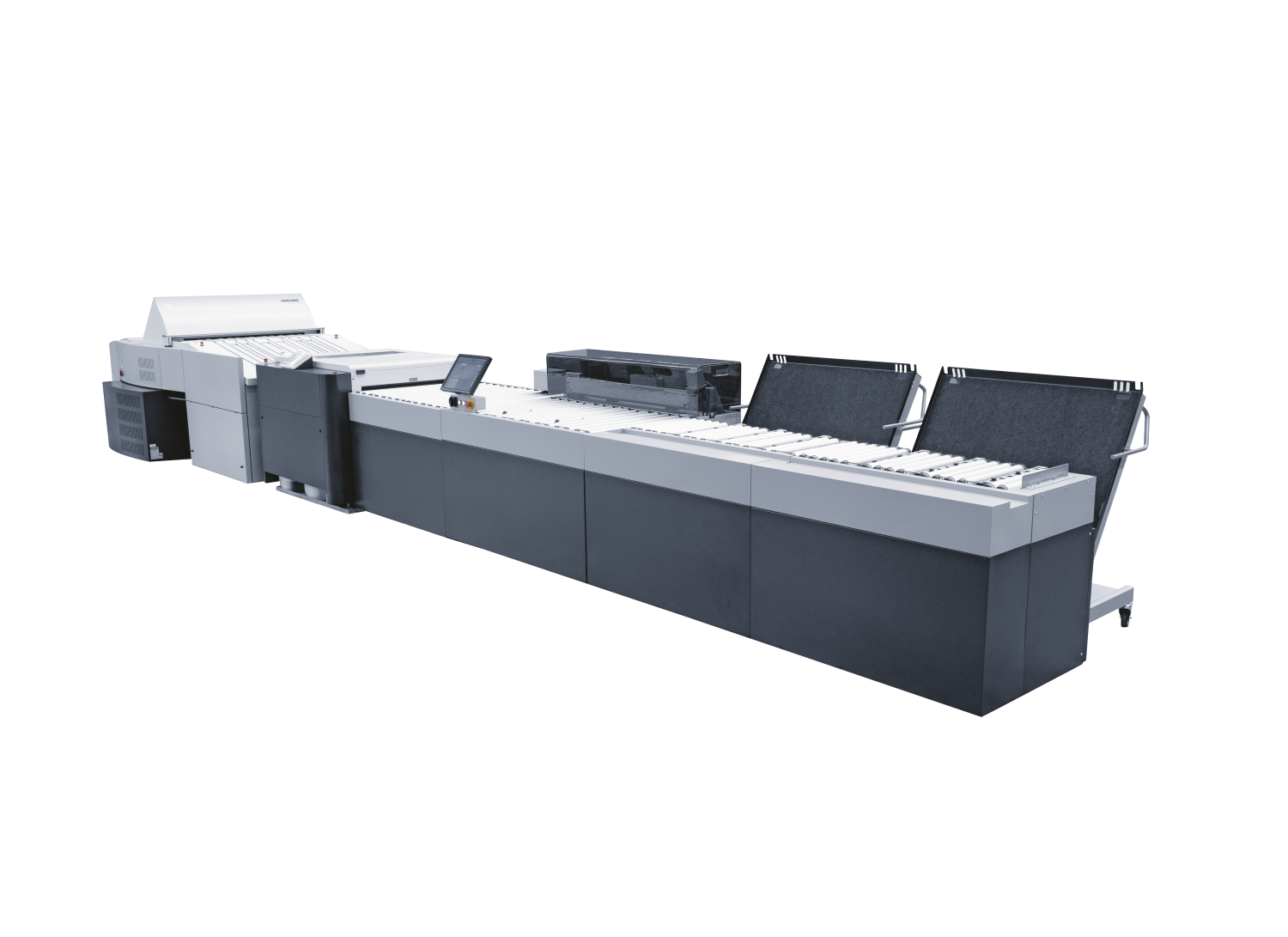

Model extensions ranging from the Dual Cassette Loader (DCL) to the highly productive Auto Pallet Loader (APL) offer flexibility in terms of cross-format handling of printing plates with up to six plate formats. The numerous configuration options with automation components make the Suprasetter 106 the most flexible and automated machine in its class.

Discover our 5 add-ons to fully automate your CtP workflow:

The Dual Cassette Loader 106 prepares the Suprasetter A106 or Suprasetter 106 for fully automatic operation. With its two loading cassettes, each holding up to 110 printing plates of different formats, it significantly reduces manual intervention and ensures smooth loading.

Thanks to the integrated transport bridge, the exposed plates are seamlessly transferred to the washing unit or an online processor, optimizing the production process and saving space. The integrated turntable also allows the plates to be rotated in a space-saving manner by moving them from a horizontal to a vertical position—ideal for use with more compact washing units.

For even greater flexibility and higher production capacities, the Dual Cassette Loader 106 can be combined with the Auto Pallet Loader 106. This perfect synergy enables maximum efficiency and optimal handling in fully automated plate production.

The Compact Pallet Loader 106 optimizes plate production in the printing industry through automation. With the ability to efficiently load up to 1,200 printing plates, it increases productivity and reduces manual steps. Its compact design and integrated turntable for rotating plates from horizontal to vertical, in combination with the Suprasetter, make it productive even without supervision. Ideal for smaller runs and an increasing number of print jobs.

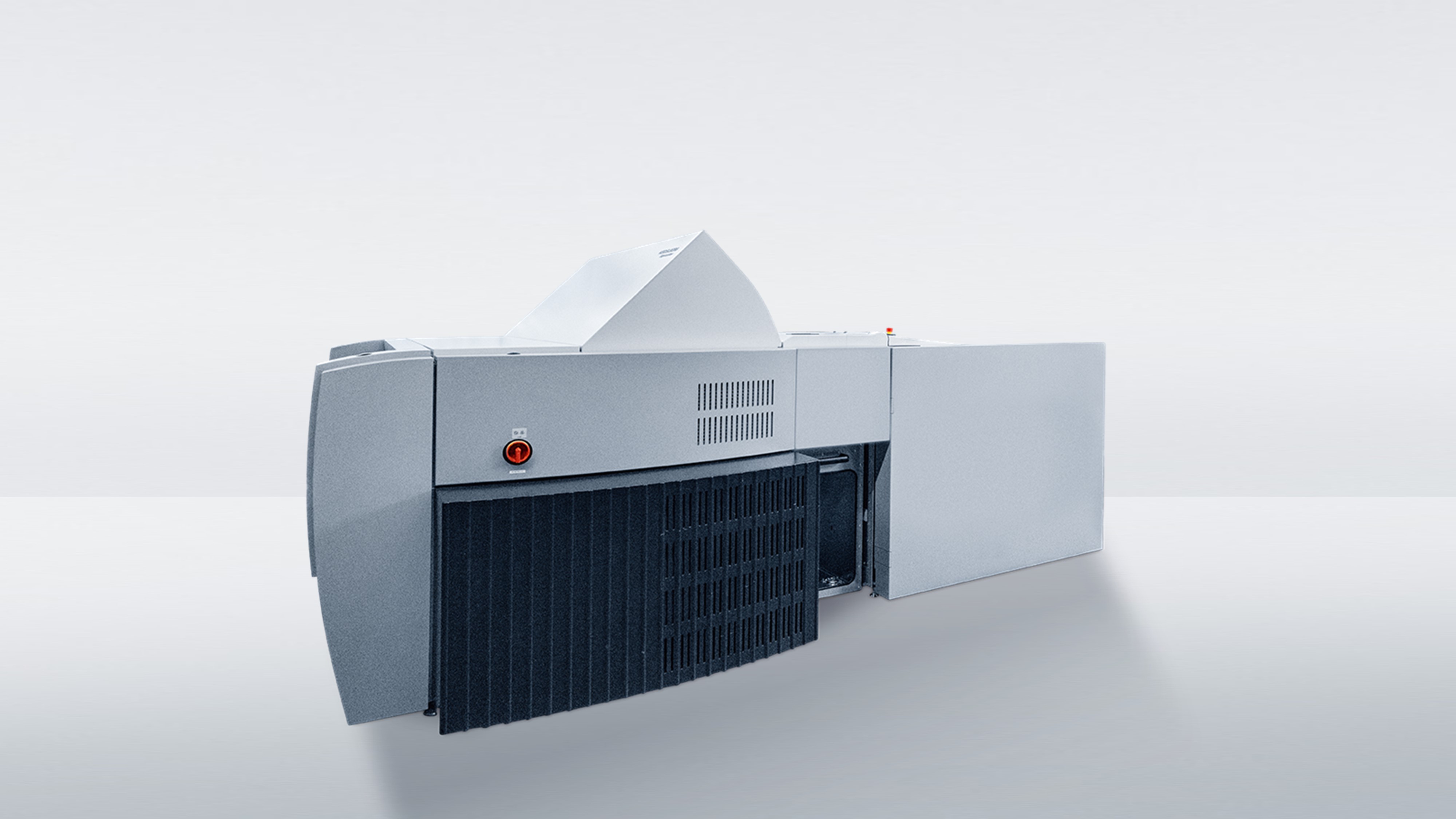

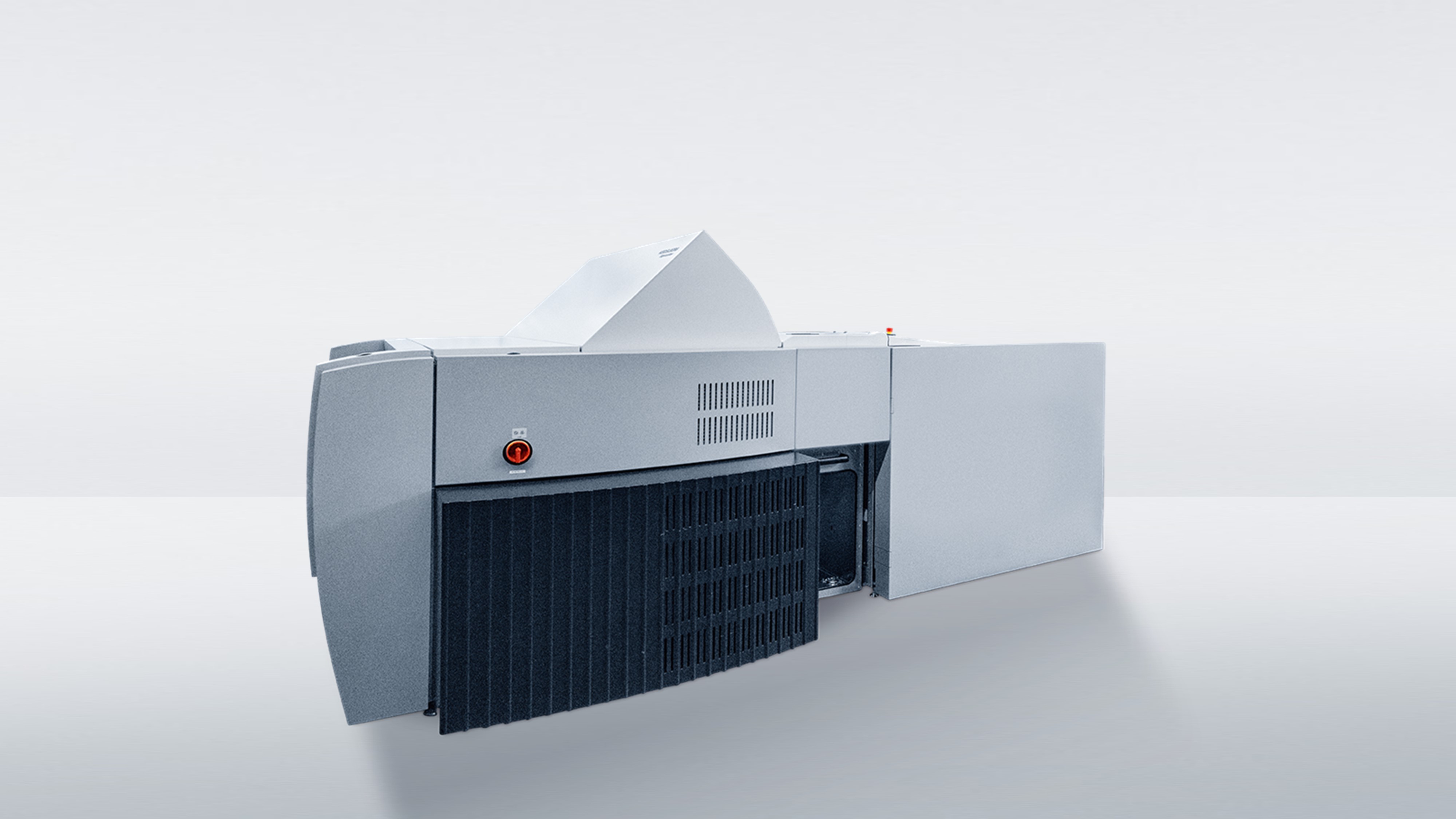

The Auto Pallet Loader 106 sets new standards in printing plate production and ensures maximum efficiency. With fully automatic loading of up to 1,500 printing plates directly from a transport pallet, the Auto Pallet Loader 106 reduces manual touchpoints and increases quality and availability in your production.

Thanks to automatic removal of the interleaving paper and scratch-free, contactless transfer of the plates, not only are work processes optimized, but the service life of the printing plates is also extended. The Auto Pallet Loader 106 is perfectly matched to the Suprasetter A106 and Suprasetter 106 – for seamless integration and maximum productivity.

The Auto Pallet Loader 106 adapts perfectly to your requirements: HEIDELBERG offers two model variants for different panel formats, giving you maximum flexibility.

Additional loading cassettes can be integrated as an option to make the loading process even more efficient. It is also possible to use a second pallet storage space so that another format can be loaded at the same time. For even faster panel production and maximum flexibility with different formats, we recommend combining it with the Dual Cassette Loader 106 or Compact Pallet Loader 106.

With these enhancements, the Auto Pallet Loader 106 ensures a smooth and flexible workflow that significantly increases your production output.

The Compact Bender complements the imagesetter line with a fully automated system for plate bending, for continuous, contact-free printing plate production.

Thanks to optional barcode recognition, the printing plates are automatically presorted according to printing press, job, and plate set and made ready for printing. The system operates without manual intervention and ensures maximum process reliability and efficiency.

In combination with the Compact Pallet Loader, this creates a continuous workflow from loading to the finished panel — ideal for modern printing companies that want to increase their productivity and counteract the shortage of skilled workers.