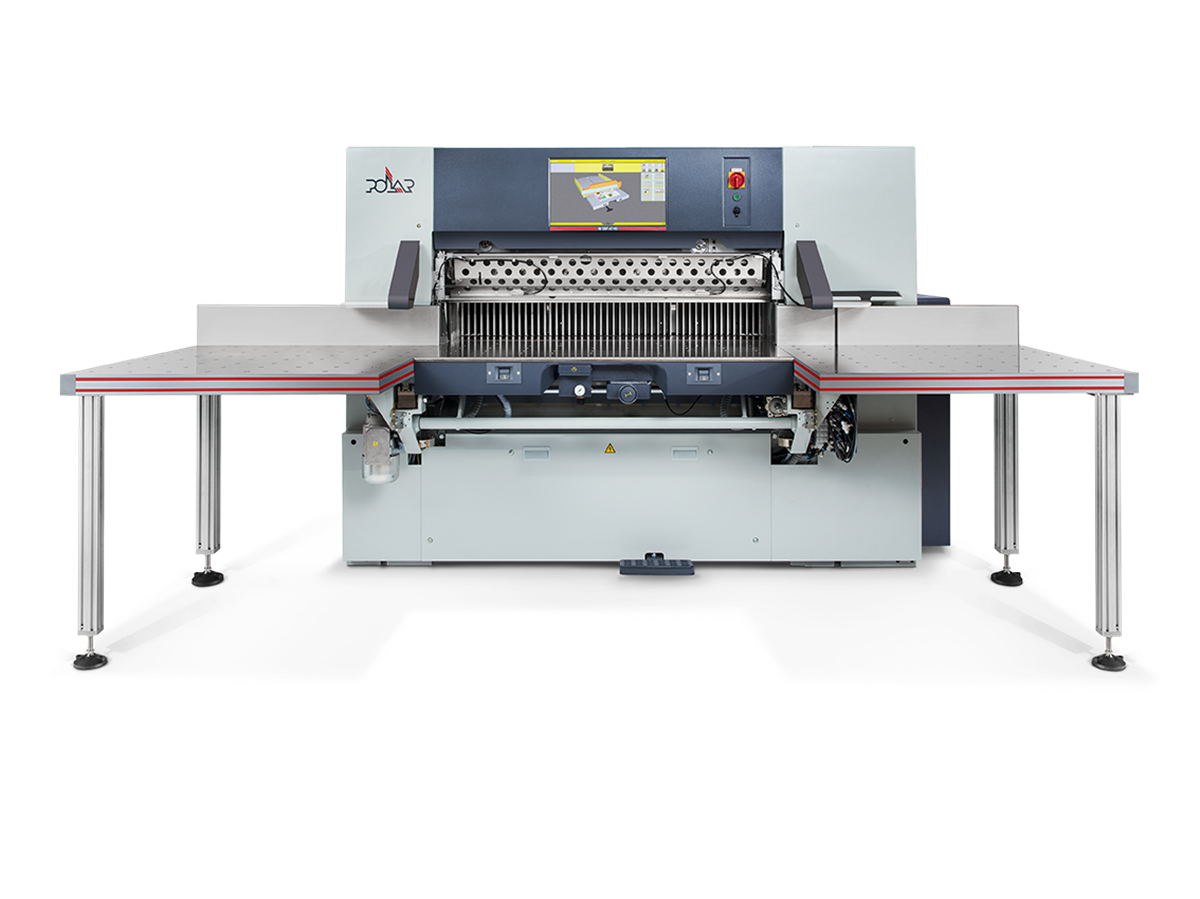

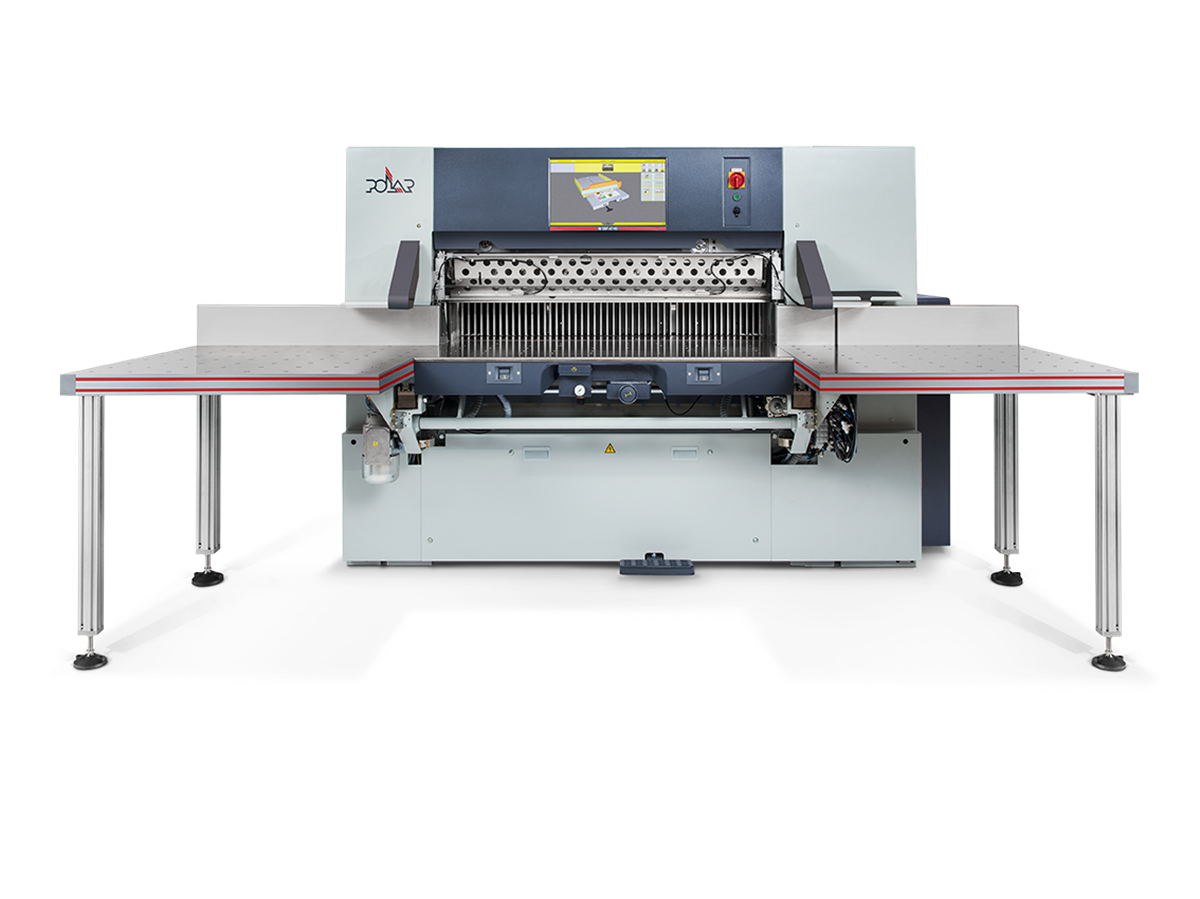

POLAR high-speed cutters deliver excellent added value thanks to the OptiKnife knife changing system, very easy operation, first-class technical service and the best resale value worldwide. With its large variety of programmable additional functions, this high-speed cutter offers impressively short makeready times and high efficiency. It is the right choice for companies that demand maximum precision and profitability from their cutting machines. When demands increase, the cutters can be upgraded to form cutting systems by adding peripheral equipment.

Model variants:

Model variants:

Model variants:

Model variants:

Model variants:

Model variants:

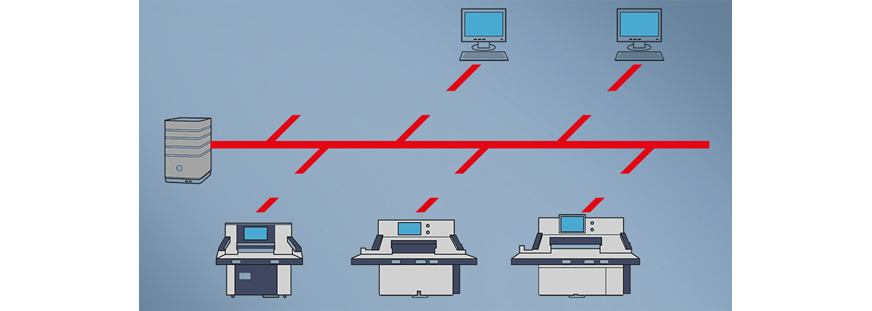

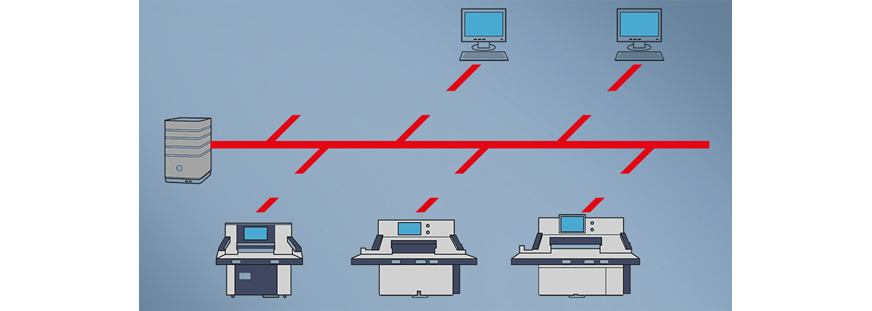

P-Net makes it possible to integrate individual POLAR components or POLAR cutting systems into the digital workflow through P-Net Connect.

Compucut: with more than 25 years of experience, we provide a benchmark for reducing makeready times. The cutting program can be easily generated outside the high-speed cutter because the sheet layout (CIP4 / JDF) is either taken over directly from prepress or the sheet is recorded manually. This means that the machine's set-up time is reduced to almost zero.

CutManager: links the P-Net on-line to the Prinect Postpress Manager of Heidelberg, and thus integrates it into the digital printing workflow. By exchanging job and production data the P-Net Service CutManager offers advantages with respect to transparency of costs and performance as well as the production planning

Barcode: Faulty operation is excluded as the correct cutting program is loaded automatically without lengthy search. The barcode reader is integrated into the left-hand light barrier housing of the high speed cutter and can be activated via a button on the touch screen monitor.