The major challenges for print shops in commercial and packaging printing are competitiveness and cost pressure, a shortage of skilled workers, digitalization and sustainable production. The Speedmaster XL 106 of the new Peak Performance Class addresses precisely these diverse challenges.

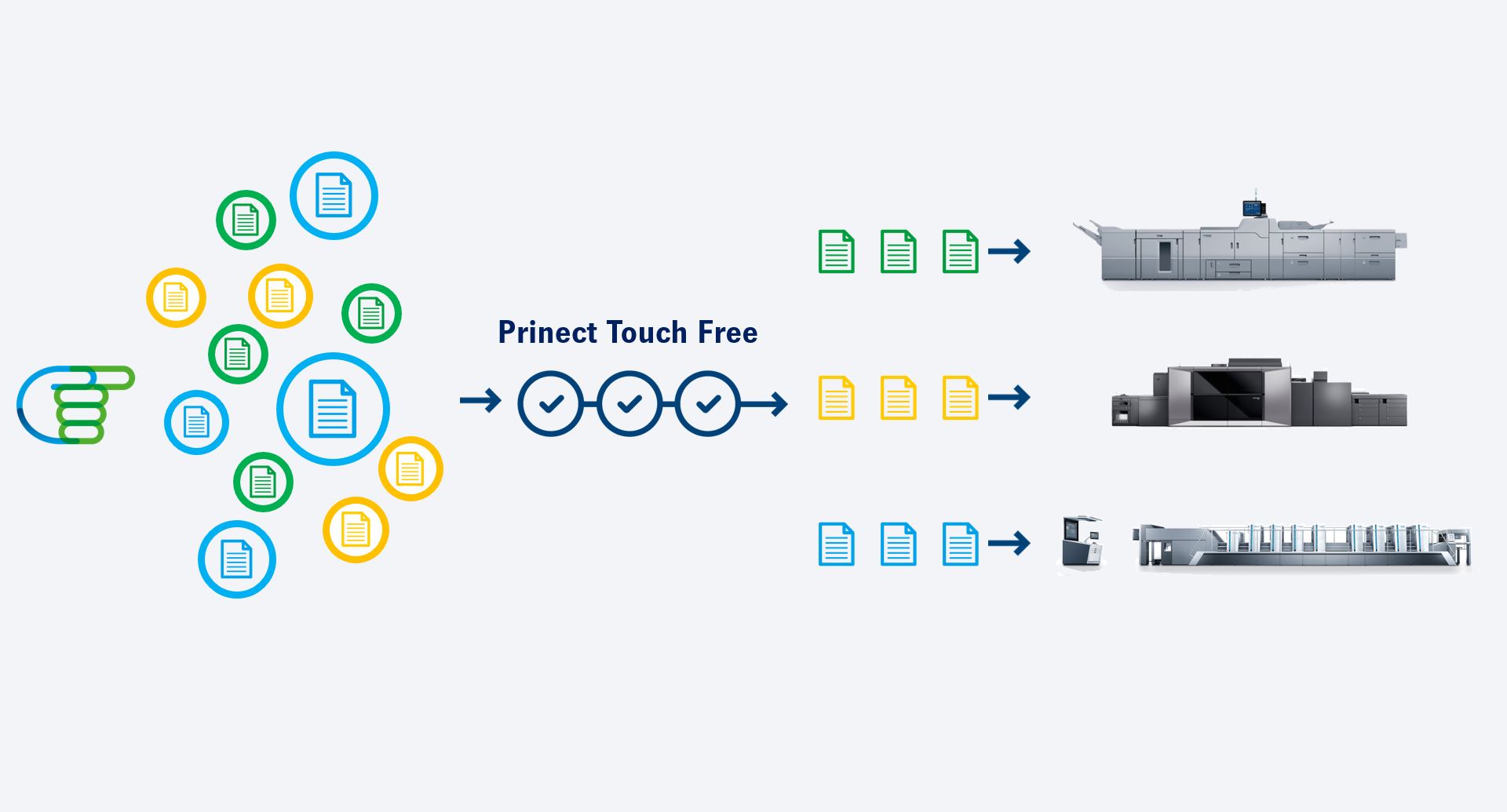

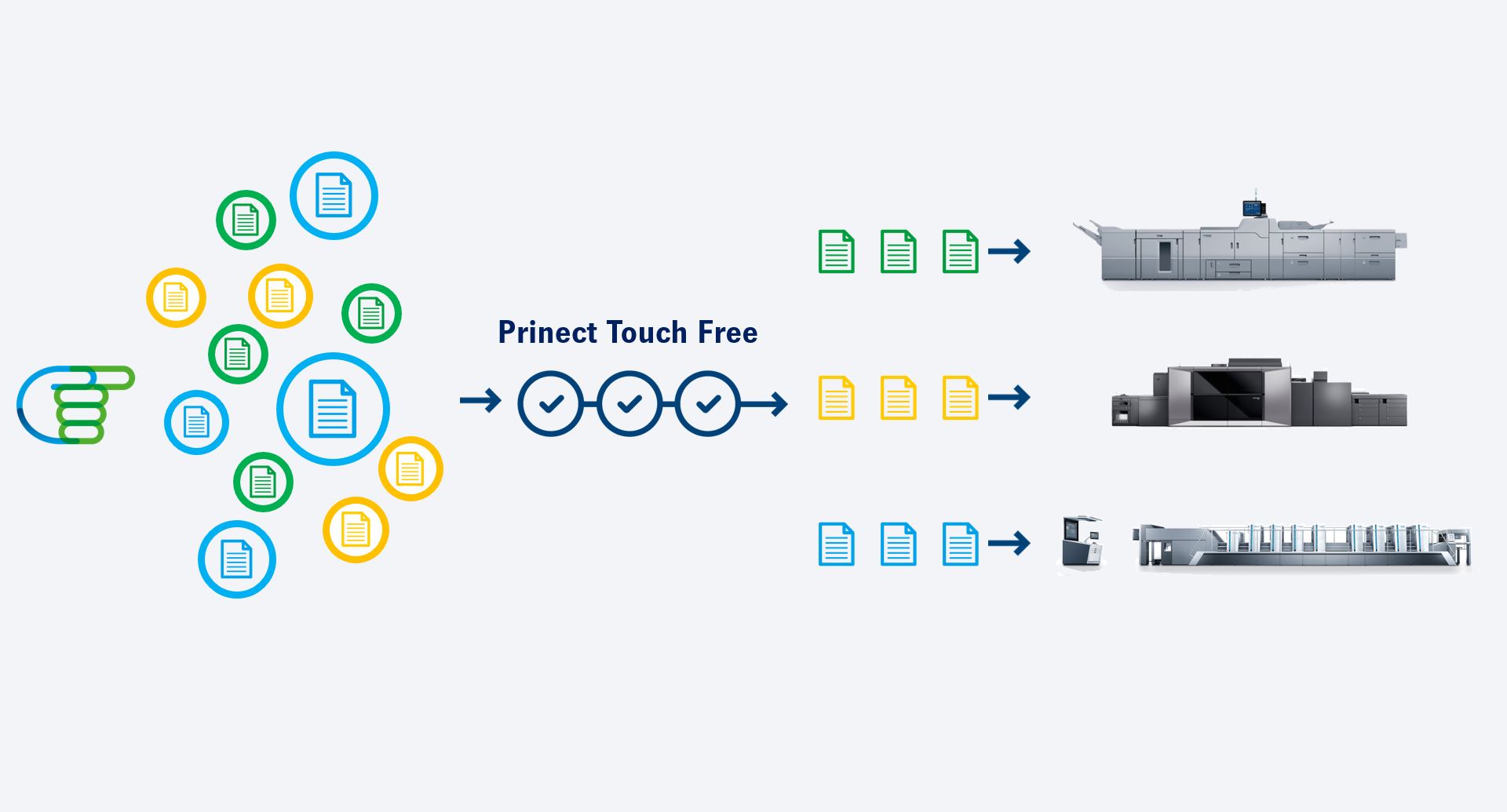

Prinect Touch Free is an option of the Production Manager that seamlessly integrates offset and digital printing into a single workflow. With the help of AI, production decisions will be made fully automatically and precisely in the future. This central control system optimizes your production process, from PDF to finished product. Optimization takes into account the entire order book in three stages, and constantly adapts to changes to ensure the most efficient production method at all times.