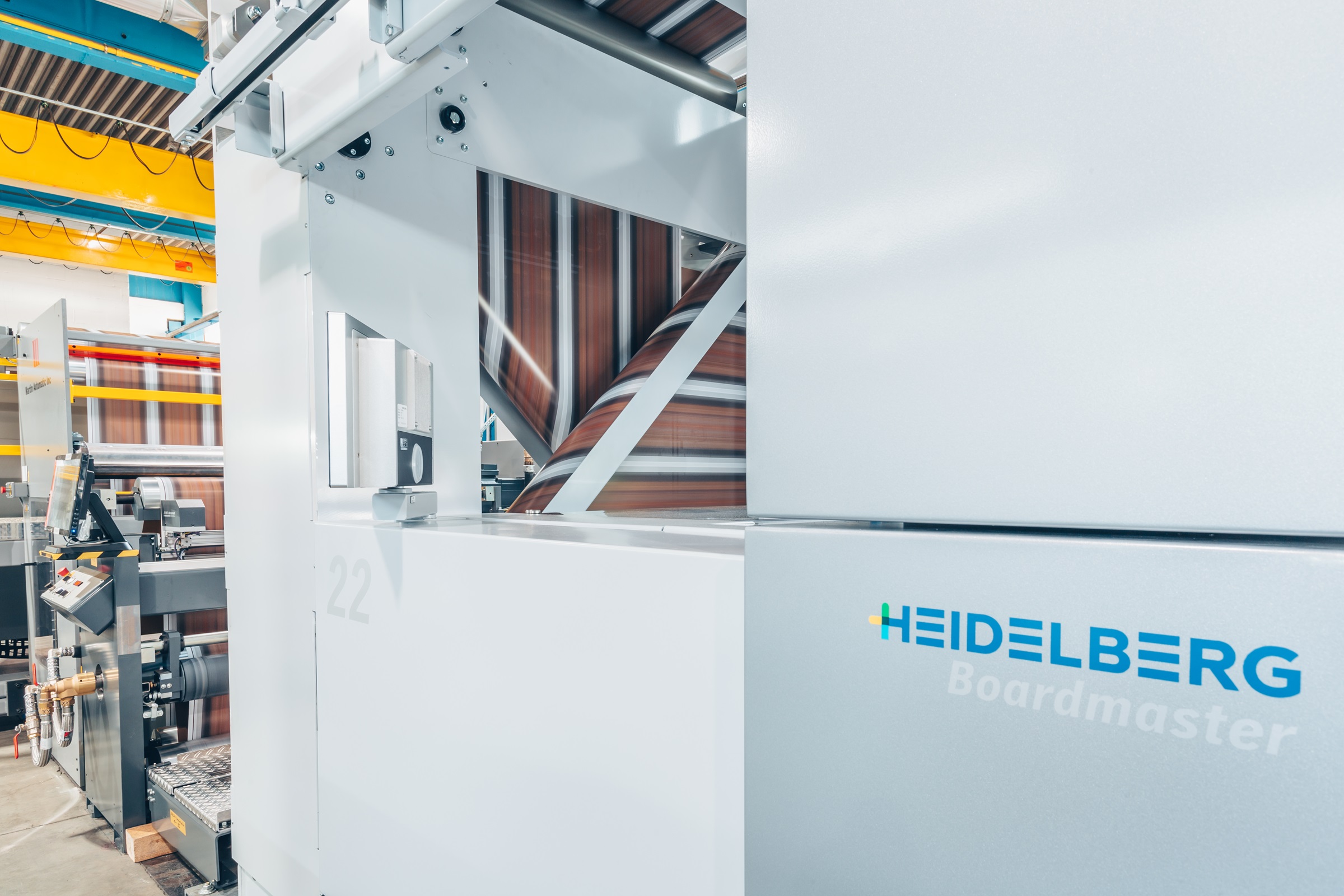

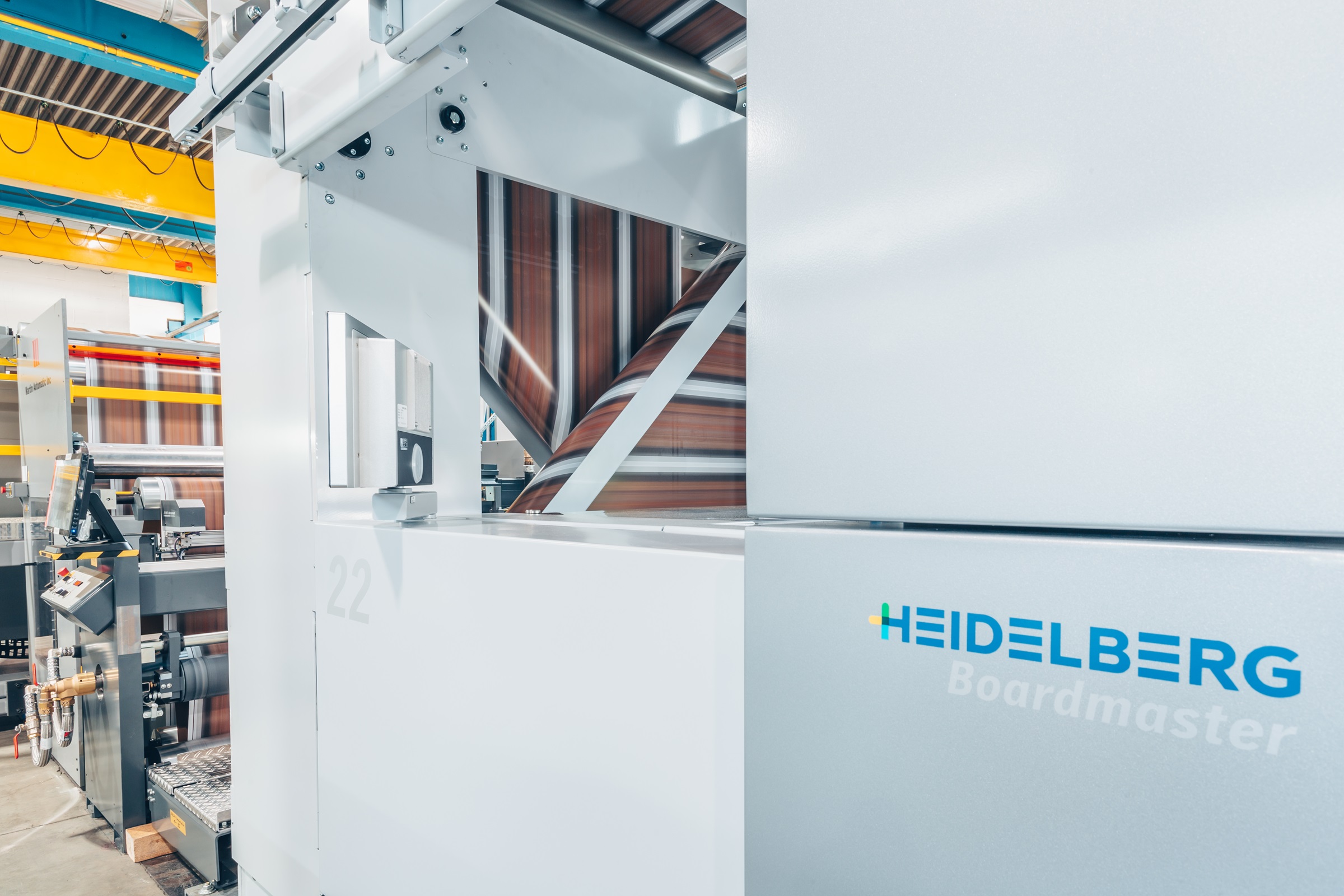

The Boardmaster is the most modern, feature-laden flexographic press available - and nothing less than a redefinition of flexo printing. The Boardmaster gives you unparalleled, continuous functionality when changing from one job to the next. Eliminate changeover downtime for good. And more than that, achieve up to an entire extra shift of production per year.

The Boardmaster ensures highly efficient operation, capable of maintaining production speeds of up to 600m/min also during the coating process. It consistently delivers output at the highest quality standards.

With the built-in coating unit, businesses can expand their offering, providing advanced coating options as value-added service. This eliminates the need for expensive offline coating processes and is a further contribution to reduced cost.

The web-turning station allows production of double-sided print jobs in one pass, increasing efficiency and productivity even more.

This option also provides for more flexibility in print job design as different effects can be applied on either side of the substrate. Precise control and monitoring of the print result safeguard high print quality.

The time you used to spend on setting up and adjusting new jobs can now be put to better use. Switching from one job to the next at a maximum speed of 600 m/min makes for best possible machine up-time.

Boardmaster can be equipped with a choice of three different print decks. In any combination they provide for producing job after job without any downtimes at a level of print quality new to flexo printing.

Adjusting impression is the single biggest time loss when operating a conventional flexo press. Boardmaster and Intellimatch automate the entire process achieving perfect impression at the same time.

Reducing substrate and ink consumption during start-up and job changes by up to 90% is made possible by the combination of Boardmaster and Intellimatch. Setting up the register with enormous waste is a thing of the past with the unique Register Assistant for Boardmaster. Even if the plate is not mounted perfectly, registration can be adjusted within seconds and while the press is running.

It saves time and waste and at the same time offers ease of operation at a new level, as all steps can be controlled and checked via the HMIs at each print deck.

The Boardmaster is designed to be especially operator-friendly for staff with any level of expertise – and this includes its setup: all touchpoints are conveniently accessible at the same level. This eliminates the need for operators to use ladders to reach control desks, a common requirement with central impression presses.

With the ability to operate the machine from multiple access points, real-time visibility of the print process is given. Operators can monitor the output exactly where it occurs and at any time during the printing process, eliminating the need to wait for the finished print.