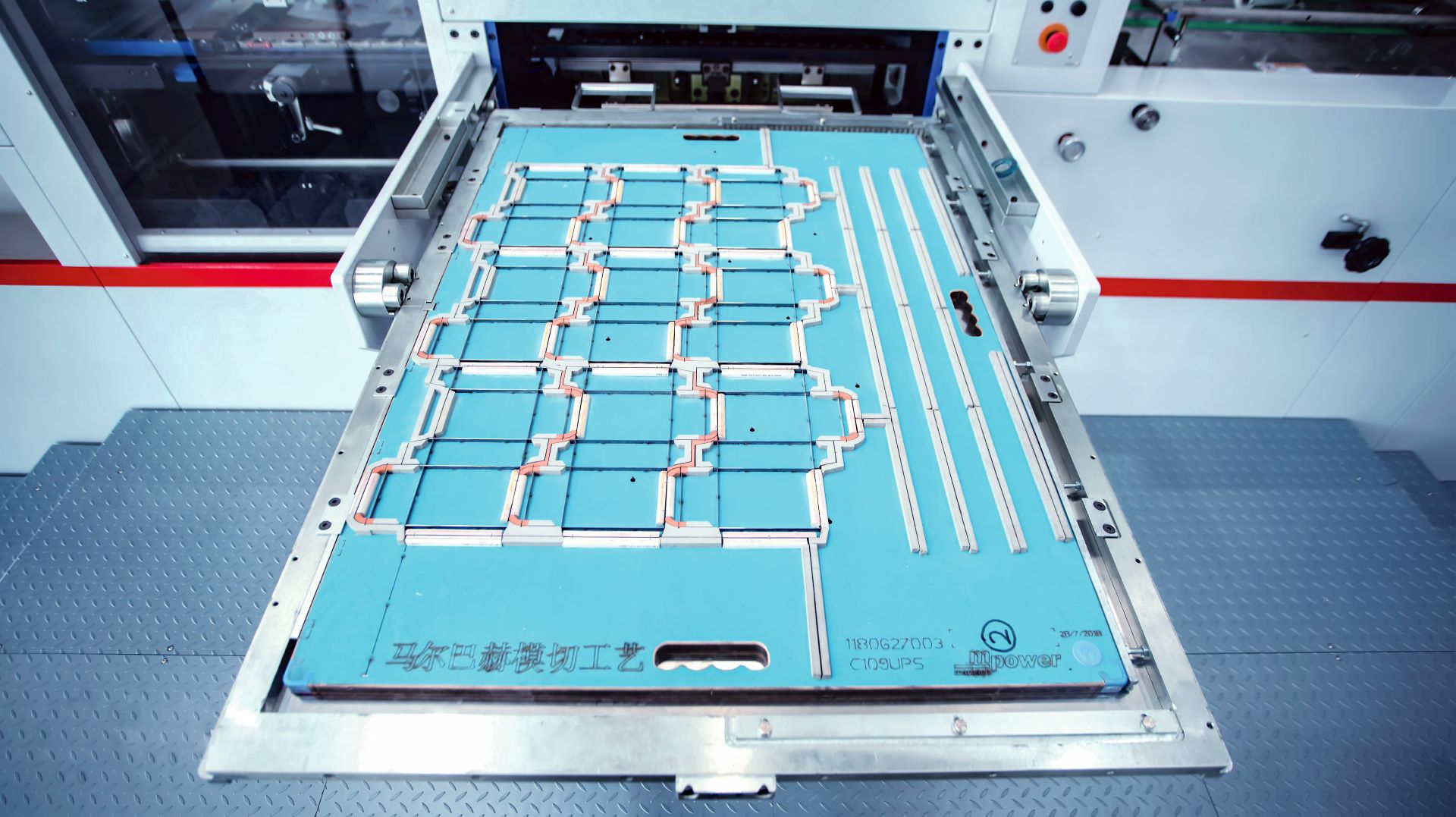

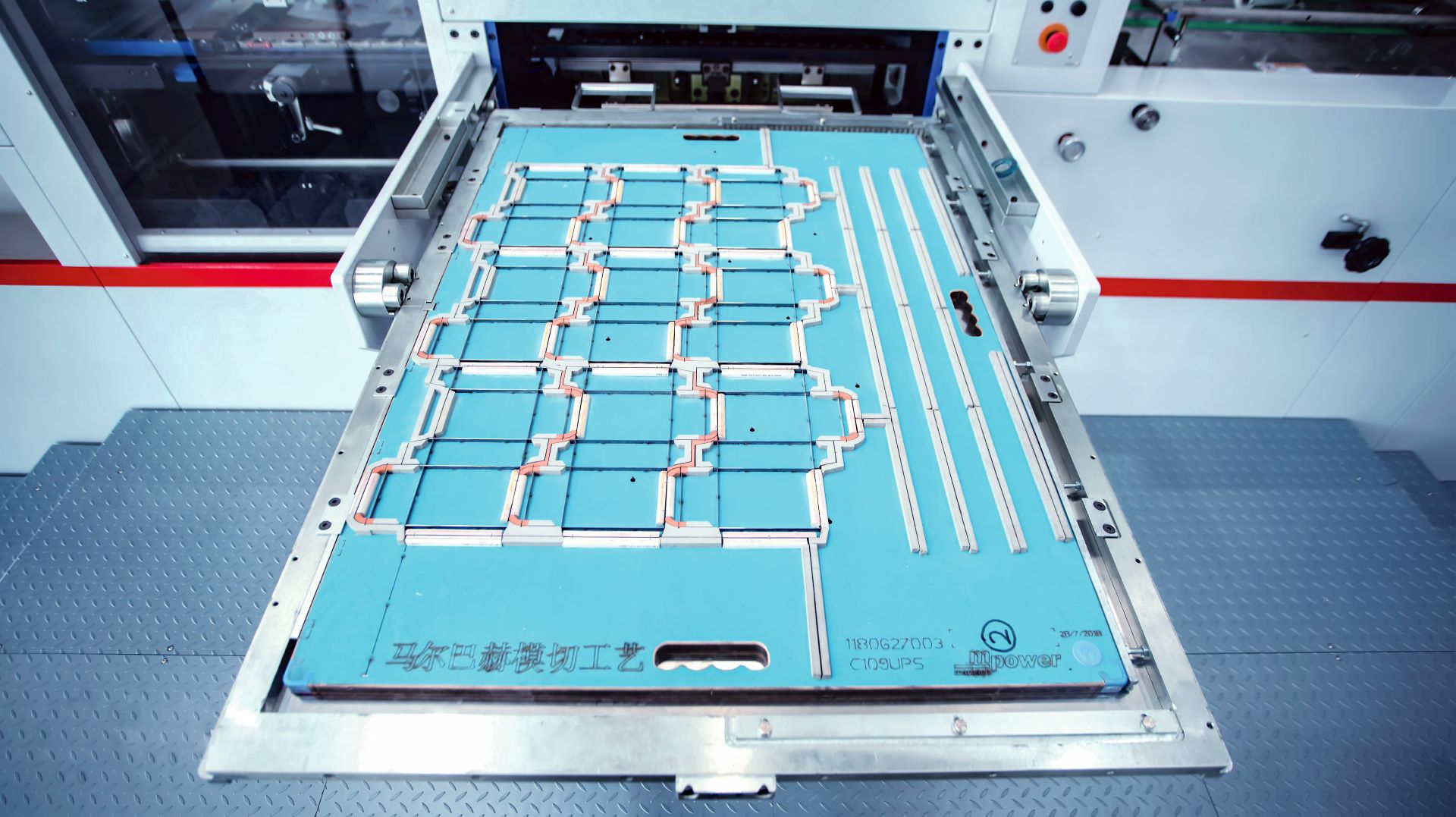

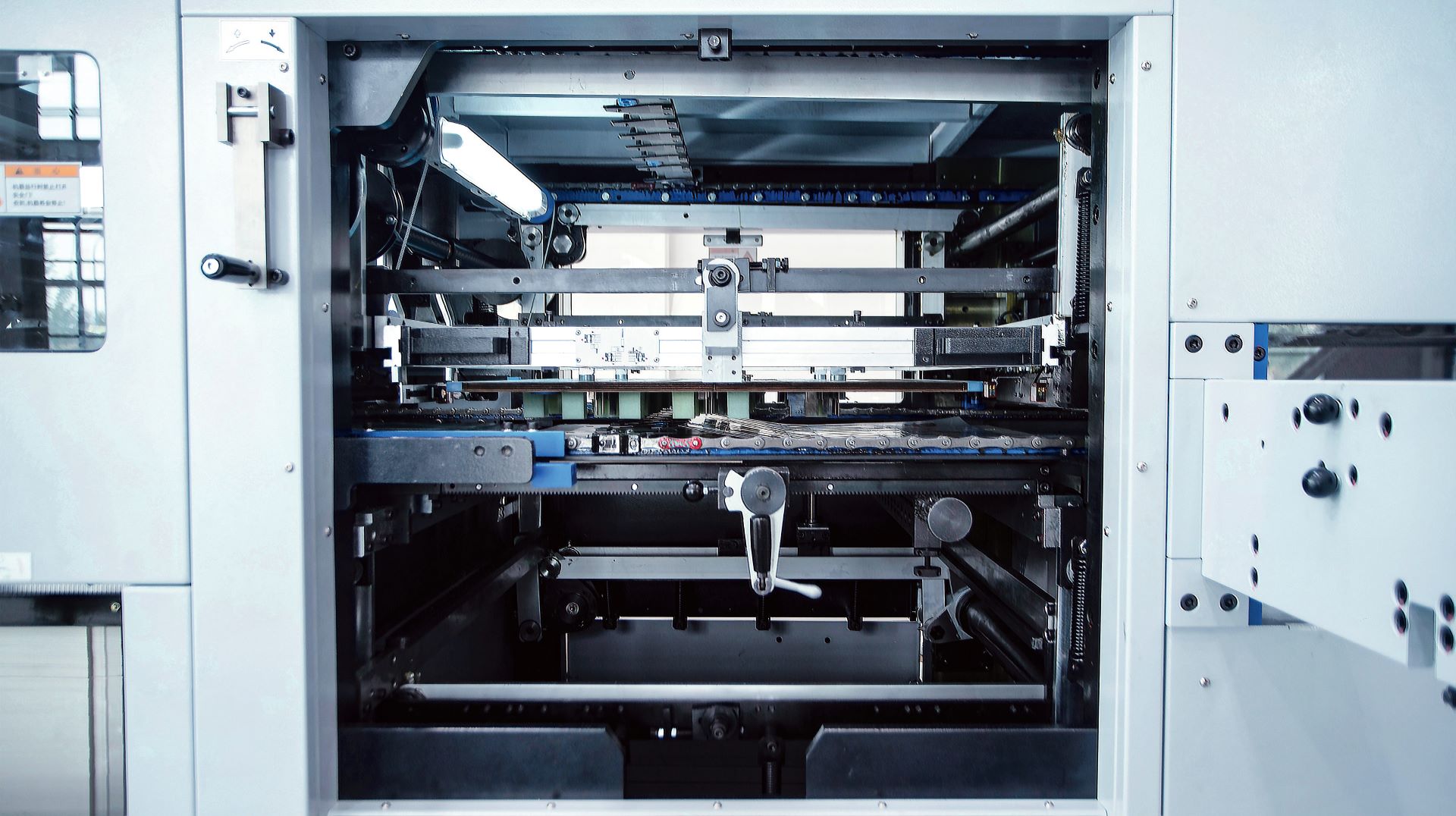

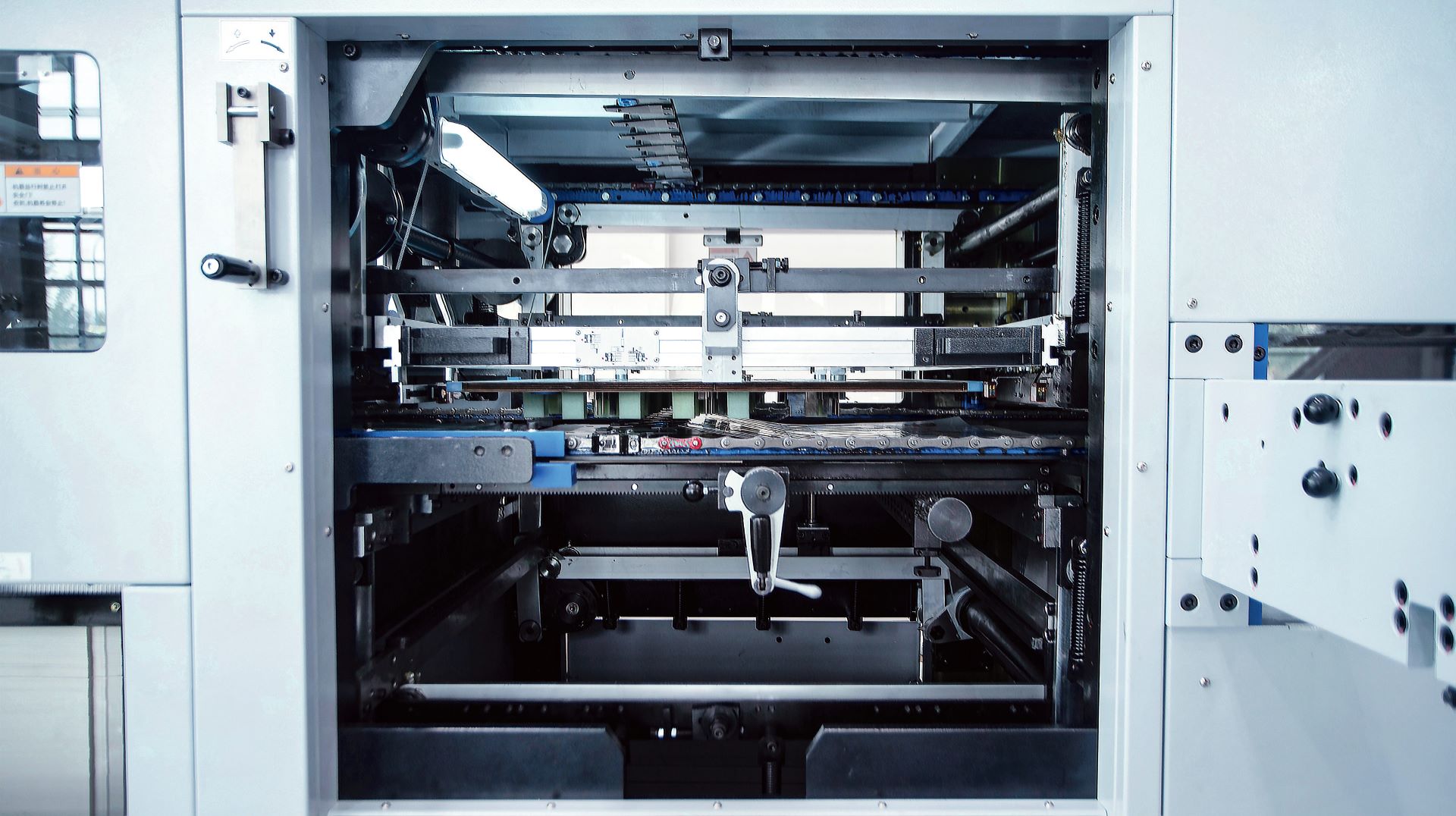

The Ecocut 106 CS is the ideal entry-level solution for commercial, packaging, and label printing. With its integrated stripping station, it efficiently removes internal waste, reducing manual work and ensuring clean, high-quality results. The center line system enables fast setup, while the motorized cutting pressure adjustment ensures precise die-cutting across various materials.

The Ecocut 106 CS offers many benefits to commercial and packaging printers alike:

Intuitive handling for smooth production

Pre-make-ready table to prepare a job outside of the machine

Suitable for diverse applications and material types

| Sheet format (min.) | 360 × 450 mm (14.17x17.71 in) |

| Sheet format (max.) | 760 × 1,060 mm (29.922x41.73 in) |

| Machine speed (max.) | 7,500 sheets per hour |

| Die-cut pressure (max.) | 300 t |

| Paper (min.) | 90 g/m² |

| Carton/solid cardboard (max.) | 2,000 g/m² |

| Corrugated cardboard (max.) | 4.0 mm |

| Feeder pile | |

| Max. pile height | 1,150 mm |

| Max. weight | 1,000 kg |

| Delivery pile (incl. pallet) | |

| Max, pile height | 1,000 mm |

| Max. weight | 1,000 kg |

| No-stop sheet feeder | n.a. |

| Machine elevation | n.a. |

| Sheet format (min.) | 360 × 450 mm (14.17x17.71 in) |

| Sheet format (max.) | 760 × 1,060 mm (29.922x41.73 in) |

| Machine speed (max.) | 7,500 sheets per hour |

| Die-cut pressure (max.) | 300 t |

| Paper (min.) | 90 g/m² |

| Carton/solid cardboard (max.) | 2,000 g/m² |

| Corrugated cardboard (max.) | 4.0 mm |

| Feeder pile | |

| Max. pile height | 1,550 mm |

| Max. weight | 1,500 kg |

| Delivery pile (incl. pallet) | |

| Max, pile height | 1,400 mm |

| Max. weight | 1,350 kg |

| No-stop sheet feeder | included |

| Machine elevation | included |

The Ecocut 106 CS is developed and manufactured by the skilled team at Masterwork and is exclusively sold and supported through the global network of trusted sales and service professionals from HEIDELBERG.