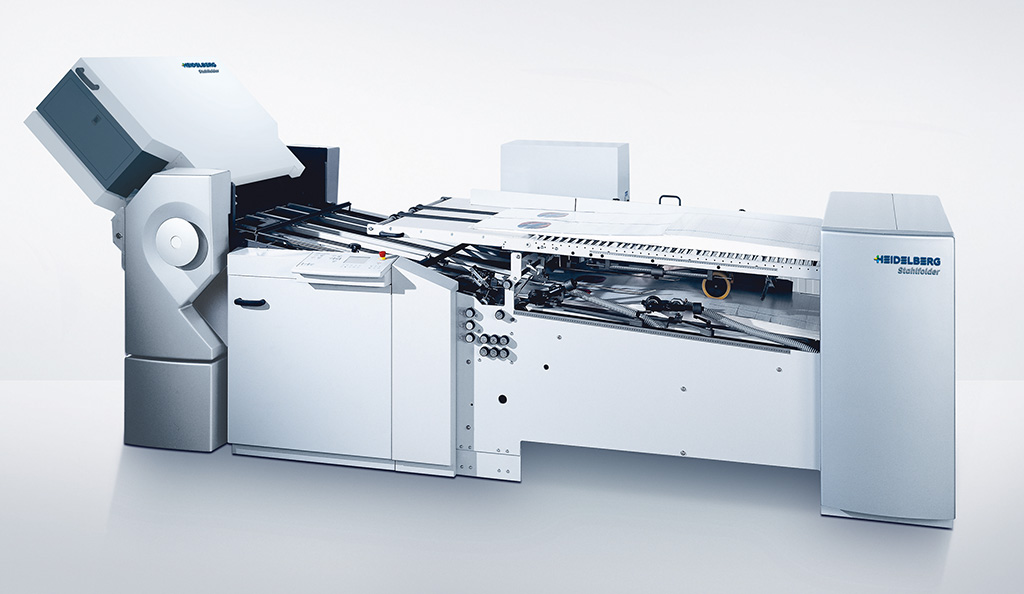

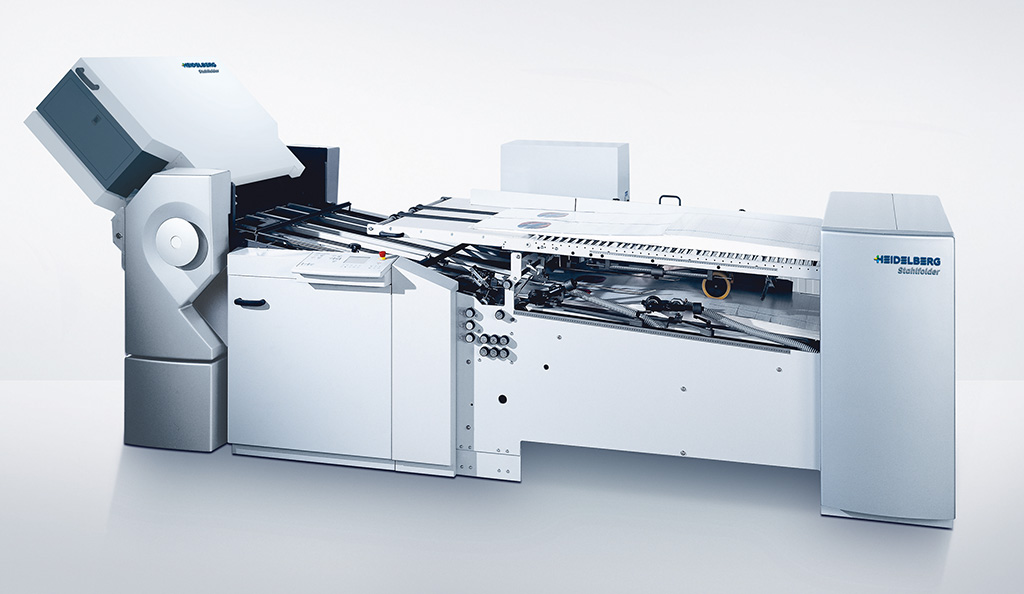

Flat pile feeders are designed to accommodate frequent folding job changes and small to medium run lengths. Other benefits include a small footprint, low investment costs and easy handling for the operator.

You can use the non-stop feeder NSF 36 at the Stahlfolder Ti 36 and Ti52 folding machines in combination with the flat pile feeder to achieve continuous operation when processing smaller formats.

Perfect sheet separation and easy operation is ensured by the lateral blowers and the proven Tremat head. Format changeovers are done quickly and easily with a few simple steps. The polyurethane coated suction wheel and the AirstreamTable guarantees reliable feeding and registration before the sheets transfer into the first folding unit.

The round continuous feeder enables the operator to continuously load paper onto the folder without interruptions. The round continuous feeders are particularly suitable for medium to large run lengths. Wavy papers, pre-folded or pre-cut sheets can be processed reliably as well as sheets printed on web presses. The AirsteamTable registers the sheets and transfers them mark-free into the first folding unit.

The versatility of the continuous enables the operator to align the stock in a shingled stream and thus creating a pre-separated stream on the loading table. The extra-long loading table provides a high capacity of sheets while being ergonomically correct loading height for the operator to load paper. The loading height of 94 centimeters is a valuable asset for the operator when they manufacture larger run lengths.

With the round continuous feeder you achieve 20 % more output at the same production capacity than with a flat pile feeder.

The pre-stacking of the sheets to be folded is omitted with the pallet feeder. More precisely, you can transport the entire printed pallet from the delivery of the printing press into the feeder of the folder. The operator can concentrate on the quality of the folded products and comfortably unload the products. To get the best performance of the folder you need the correct delivery as well to make it a one man operation.

The pallet feeder requires the least amount of effort for the operator. This helps you to achieve maximum productivity for your folding production. The maximum stacking height of 1.20 meters is optimally matched to the stacking height of printing presses. The Tremat guarantees constant air separation of the sheets and transfers the sheets separated onto the AirstreamTable. Thus, the pallet feeder is suitable for large printing formats and all run lengths.

The PFX pallet feeder allows you to feed the sheets shingled and underlapped into the first folding unit instead of feeding them conventionally with a sheet gap. This feeding technology on our folder is very similar to today’s printing presses. The underlapping of sheets (shingling sheets) on the infeed register table increases the amount of sheets that can be processed by nearly half over conventional sheet gap feeding at the very same machine speed.

The pallet feeder PFX secures you the highest efficiency for your industrialized folding production. The processing of perfect pallets and uneven stacked pallets is handled reliably by the PFX.

The separation of the paper with pulsed air pre-separates the sheets on the pallet. The sheets are reliably transferred onto the AirstreamTable from the feeder in conjunction with our combined two-stage sheet acceleration via an overhead suction wheel on the sheet trailing edge and the underlying suction wheel near the entrance to the register table. This revolutionary feeding technology on the PFX feeder is easier to set-up than conventional feeders, since all settings of the Air Management can be stored and retrieved when needed.

With our peak performance folding machine Stahlfolder TX 96 equipped with the pallet feeder PFX you can achieve performances of over 18,000 sheets per hour in the production of 16-page signatures in the final format A4.

The Tremat is our proven sheet separation system that is mounted on the rear edge of the pile. It can be easily tilted up for maximum ease of use when loading the feeder table. The height adjustable blowers on the Tremat ensure constant air separation of the pile - that allows the large lifting suckers to process single sheets. This is a prerequisite for reliable sheet feeding with up to 45,000 cycles per hour.

The AirstreamTable of all Stahlfolder TH/KH folding machines is easily set by the operator. This proven technology secures the sheet against the prism side guide for sheet alignment with maximum precision. The prism laser cut side lay and the constant air circulation from our air stream system aligns the sheet exactly and leads them mark-free into the first folding unit.