The small and quickly adjustable Diana Easypacker allows semi-automatic packing of folding cartons into shipping cases complementing manual packing significantly and thus increasing ergonomics and performance. Thanks to its simple operation and handling, operators can easily pick up the cartons coming out of the folder in a shingled flow and place them into the shipping cases.

The machine can be also expanded with an ergonomically designed packing table to ensure more efficient packing, plus an indicating counting pulse from the gluing machine allows the folding boxes to be removed in exact quantities.

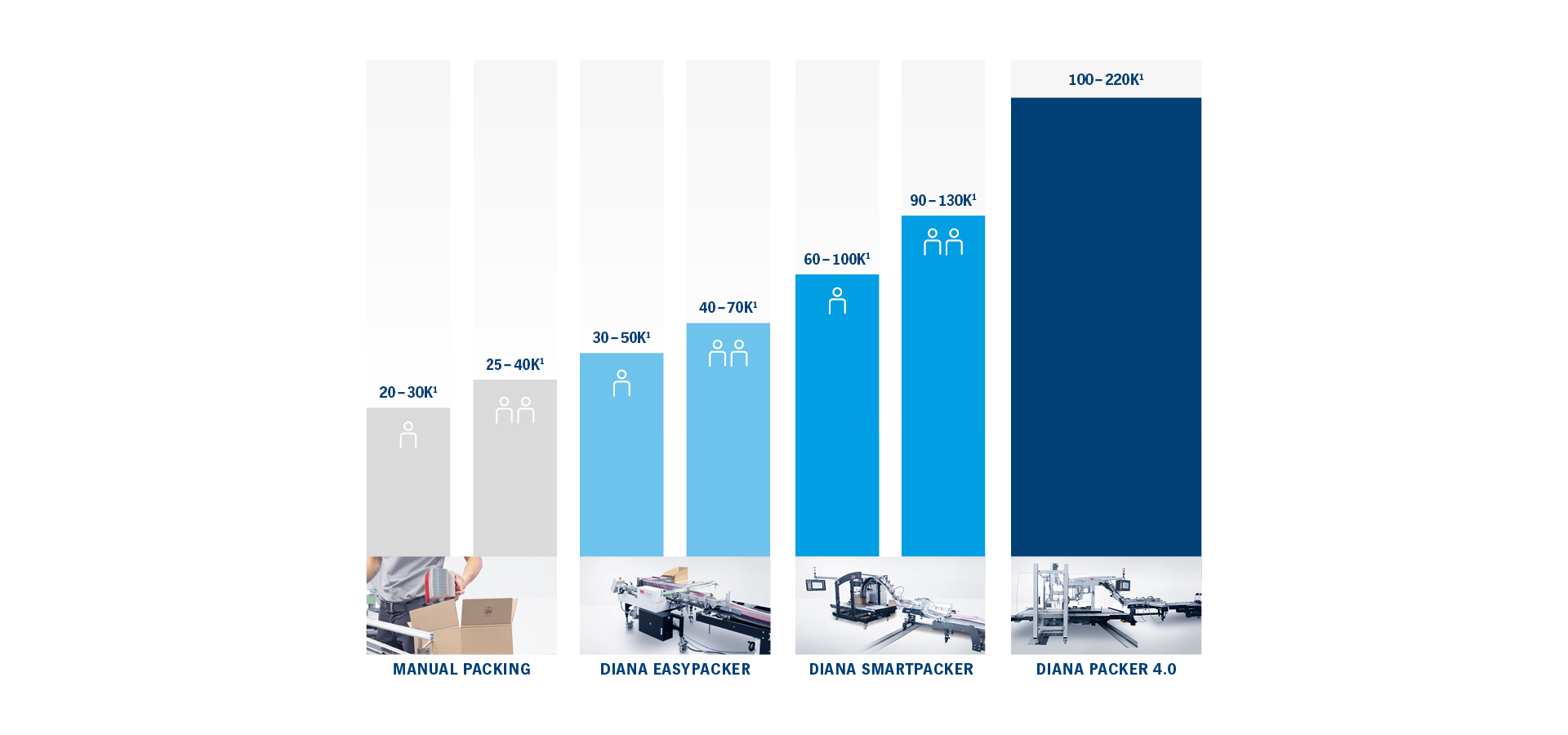

With its automation and flexibility, the Diana Easypacker can increase packing output by up to 50% compared to purely manual packing of folding boxes. It is perfect up to a speed of 70,000 glued cartons per hour and can be operated by 2 people for the highest performance requirements.

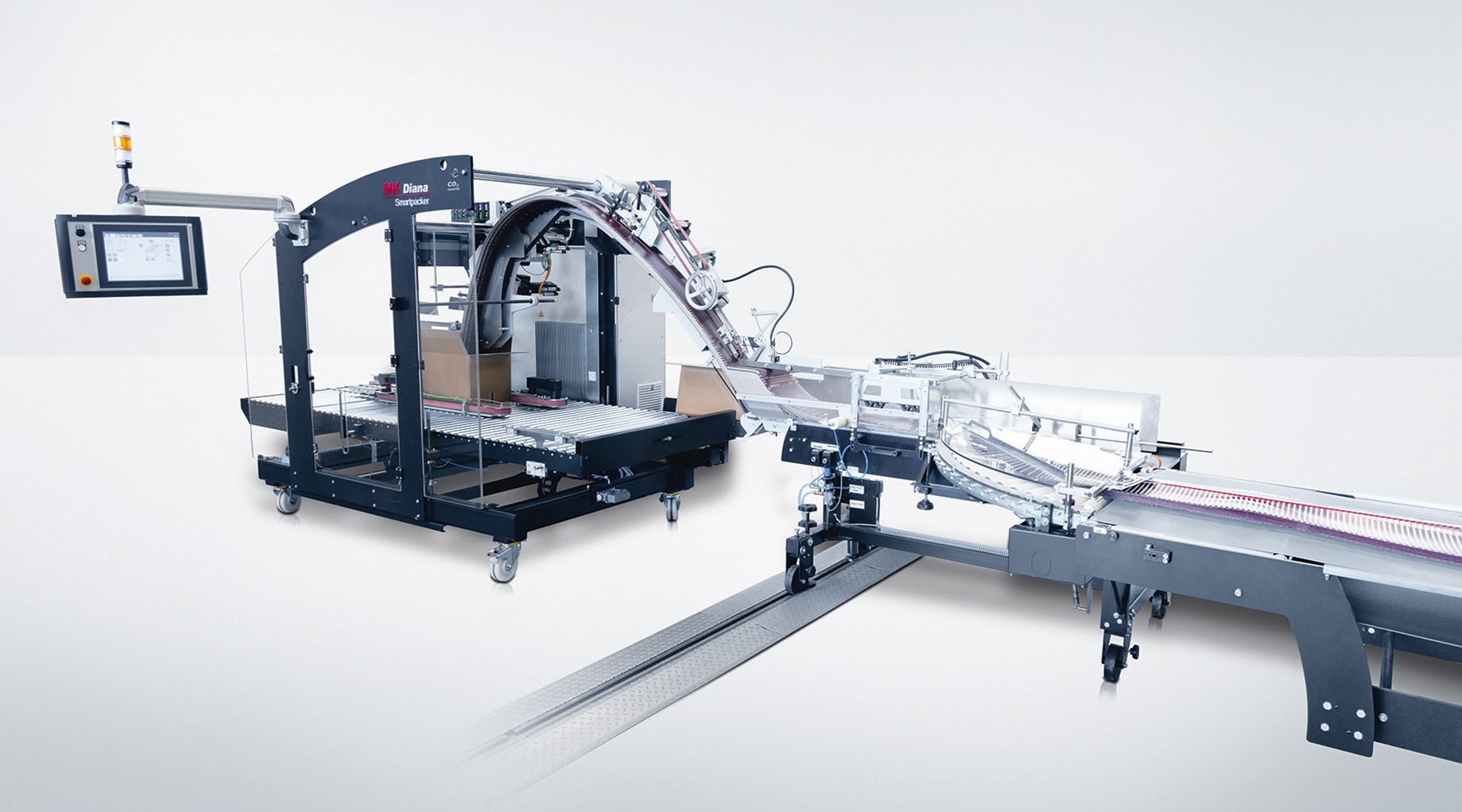

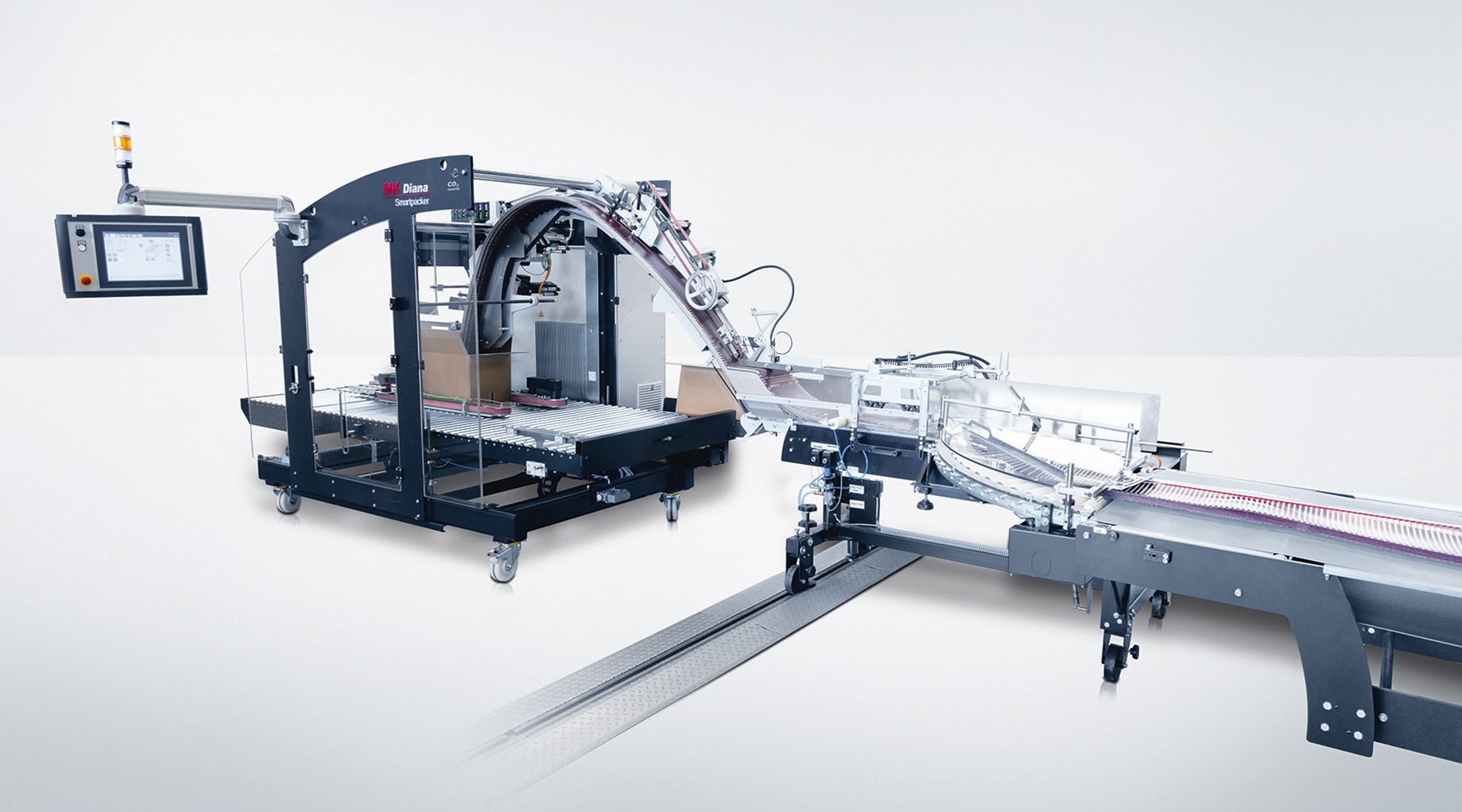

Thanks to its small footprint, compact design and flexibility, the Diana Smartpacker can be easily integrated not only into any existing production environment and workspace but with third-party folder gluers as well.

With its automated solutions, the Diana Smartpacker is as efficient as it can get in its category providing up to 130,000 glued cartons packing performance. With automated box count and filling, your employees just need to take care of the shipping cases when they are fully packed. Compared to the Easypacker, the Diana Smartpacker offers more automation making packing more accessible for businesses in any size of the spectrum.

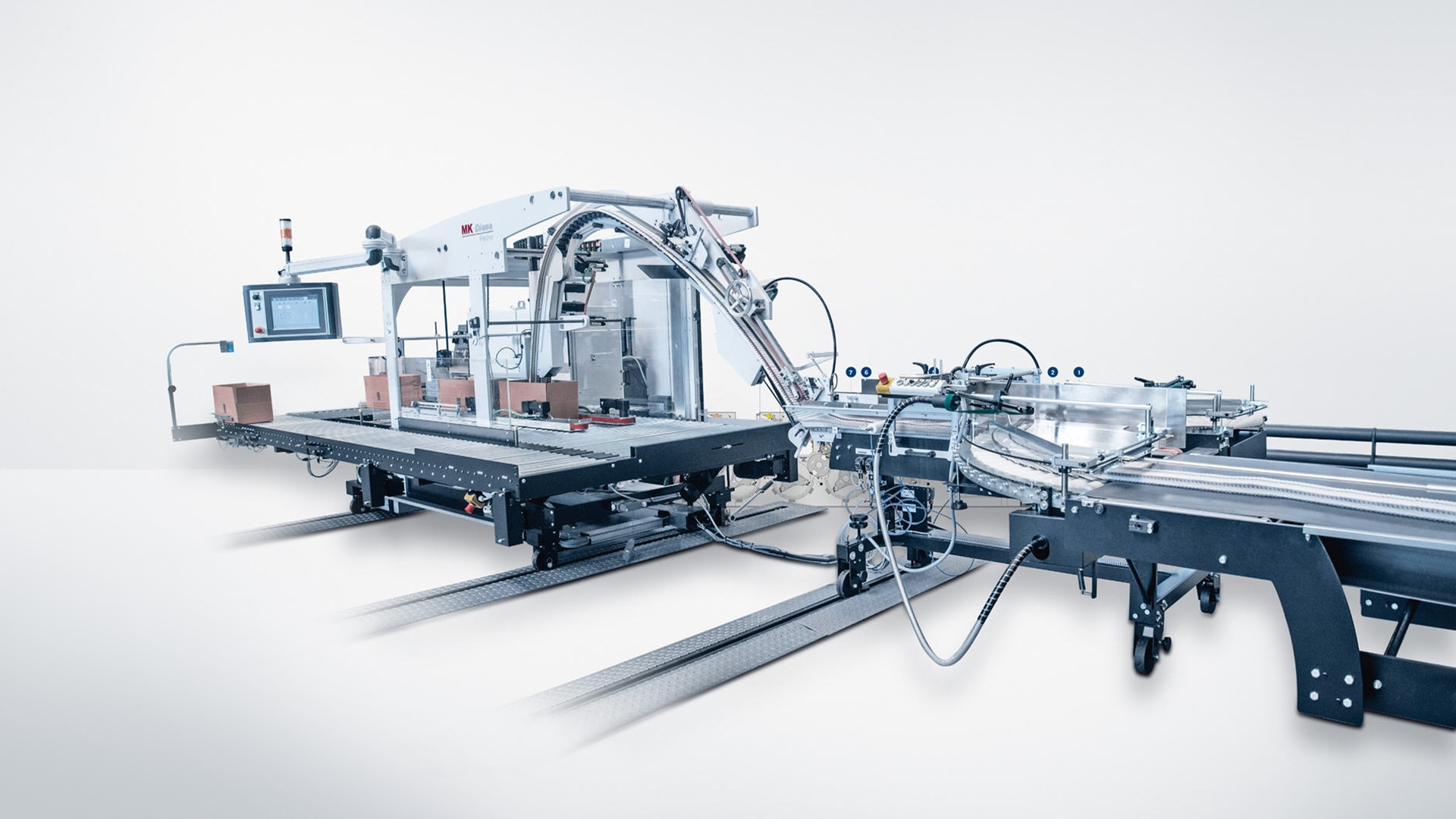

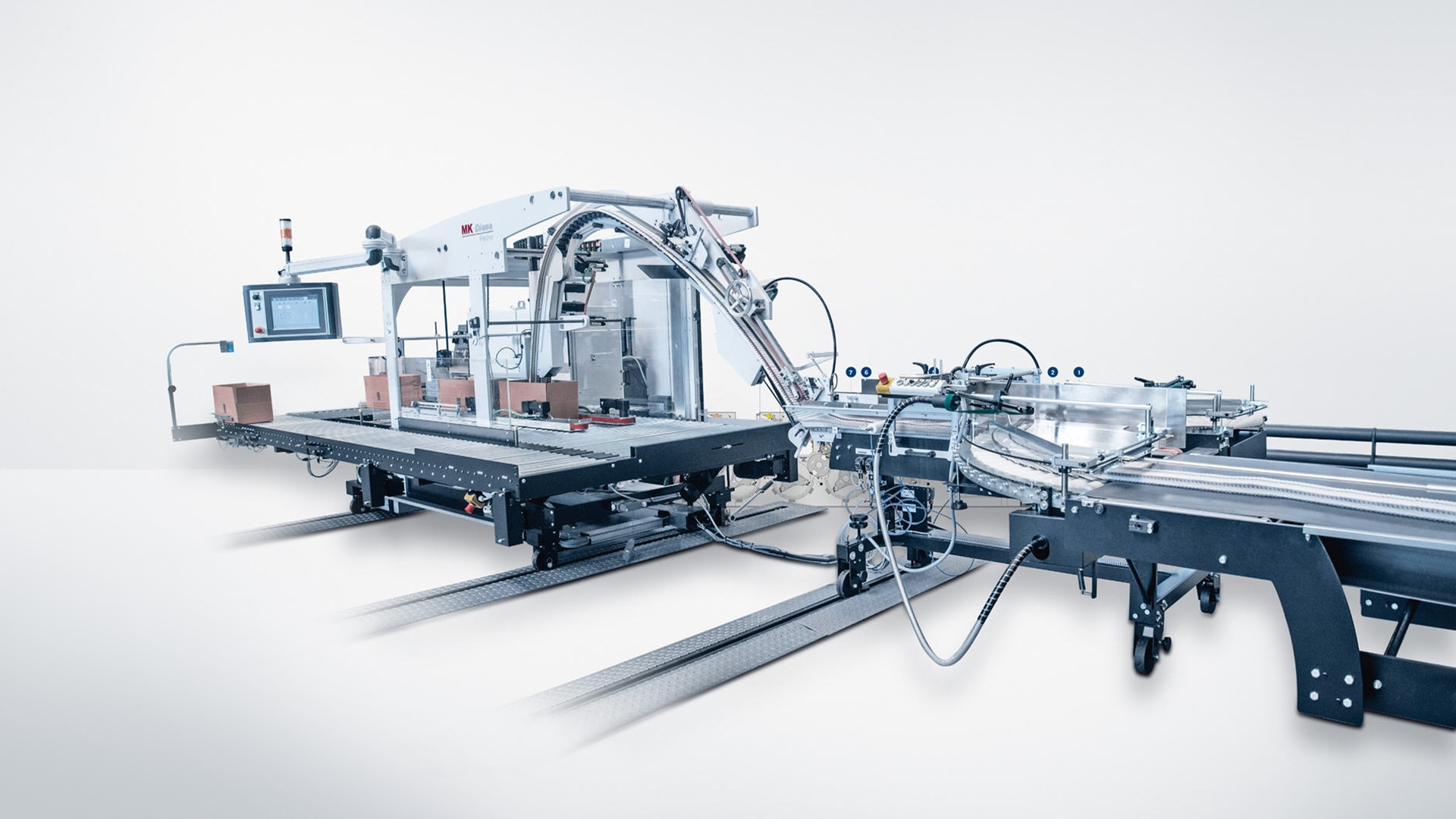

With an output of more than 200,000 glued cartons per hour, the Diana Packer 4.0 is leading the way of our packing portfolio by keeping pace with any high-performance machine and allowing the highest production speeds for folding carton gluing.

There is no longer a bottleneck when packing finished glued cartons: via simple touchscreen, automatic calculation of setting data and reduction of setting elements, Diana Packer 4.0 cuts makeready times by up to 50%, hence the unit costs per carton are reduced, saving your business time and money.

By connecting the Diana Packer 4.0 to an automated Diana folder gluer, the dimensions of the blank to be packaged can be transferred to the packer, reducing makeready times even further.

Besides next level automation, an integrated laser system ensures reliable counting of the cartons, and for greater quality assurance, the removal of one or more sample cartons can be specified, and a box is then added to the outer carton in turn to ensure optimum filling.

¹Cartons/hour; estimation may vary depending on carton format and style.

The Diana Packer is developed and manufactured by the skilled team at Masterwork and is exclusively sold and supported through the global network of trusted sales and service professionals from HEIDELBERG.