As a manufacturer of tailored, high-performance inline flexo printing presses we design and are constantly enhancing your system with the specific requirements of your customers and the market in mind. What sets our range of flexo printing presses and flatbed die-cutters apart is more than web width, run size, and level of embellishment. When designing your flexo printing press, we look at your portfolio as well as your planned or existing printing system.

Tell us your requirements – together we will find the right solution.

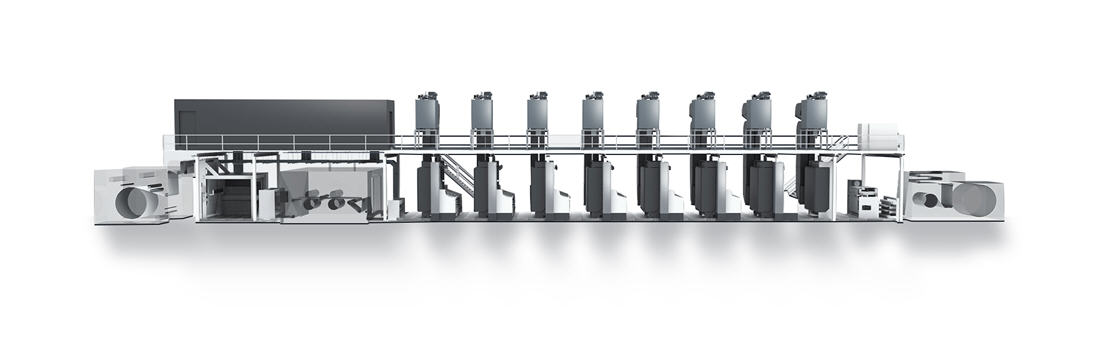

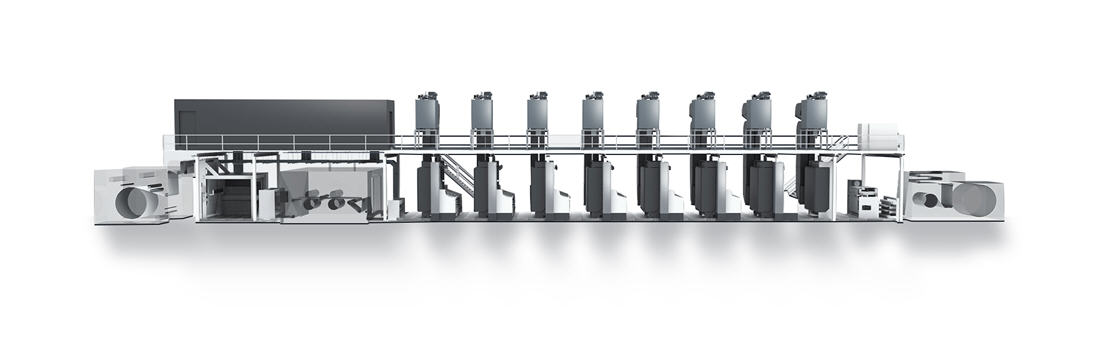

The Boardmaster addresses the key challenges facing packaging specialists: Cost pressure, productivity, shortage of skilled workers, and sustainability. This state-of-the-art wide web inline flexo printing press is also an alternative for numerous packaging users of very large-format offset equipment (VLF).

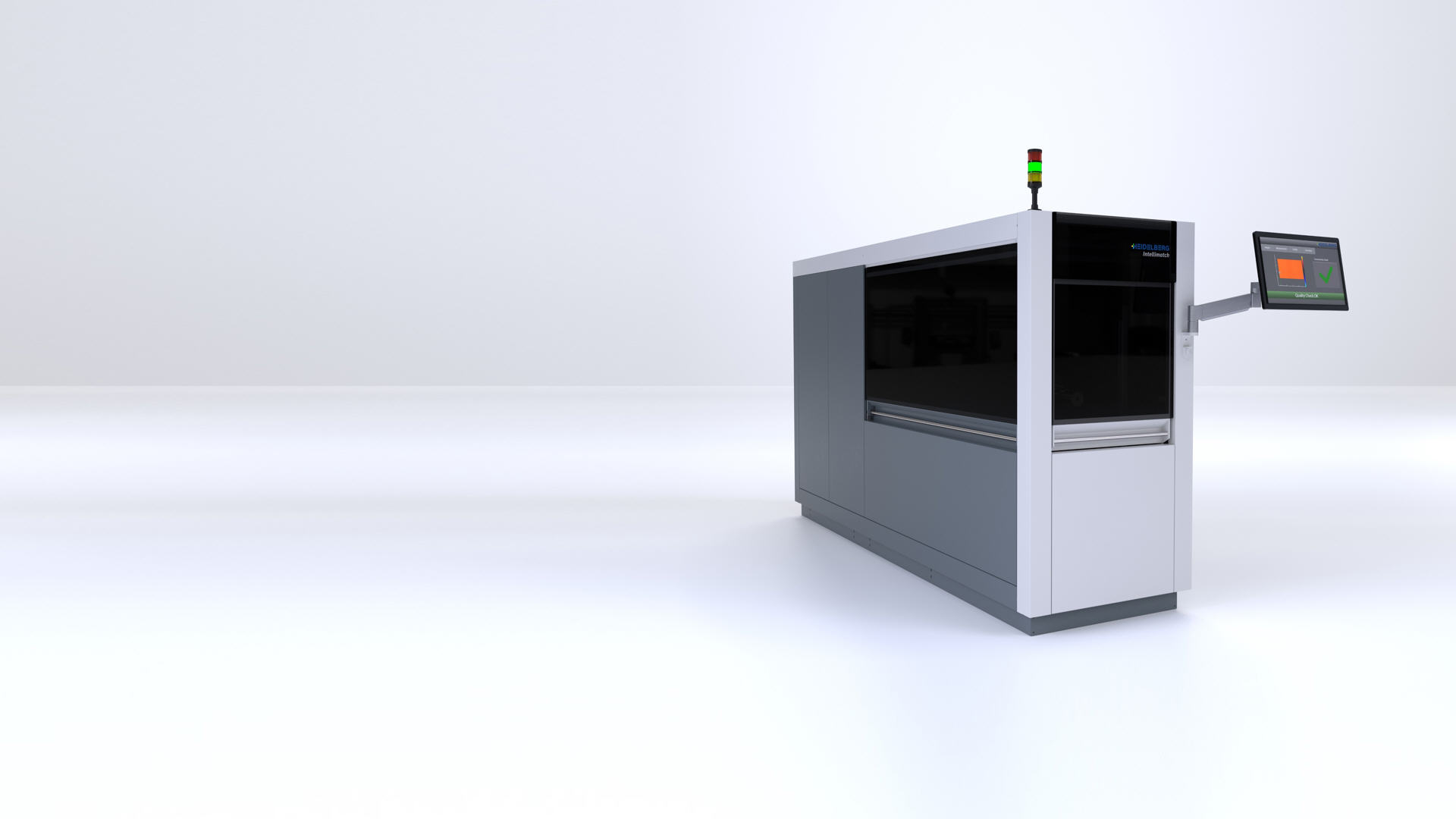

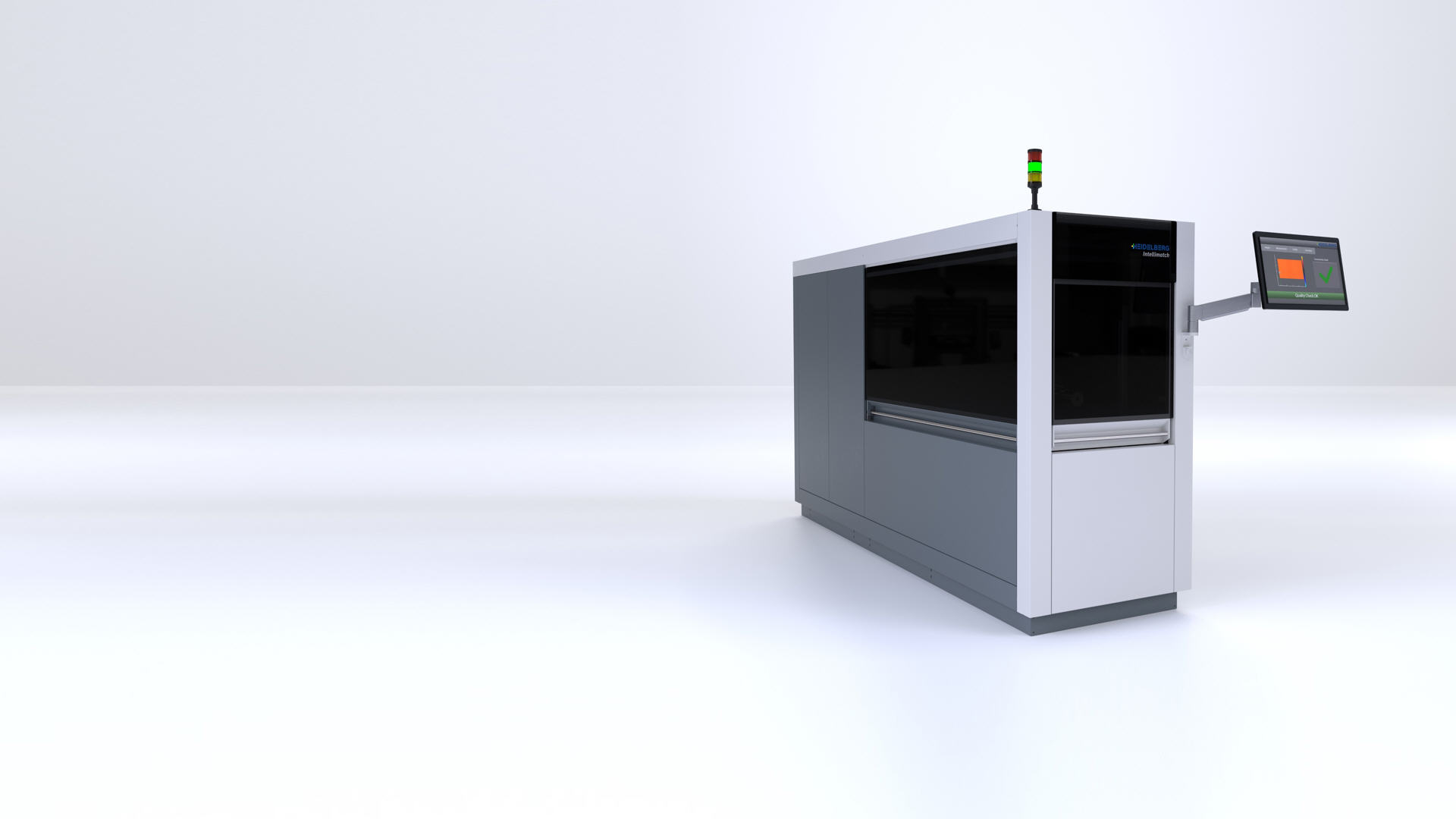

This unique offline printing plate and sleeve scanner provides all press parameters for the Boardmaster. Intellimatch can also detect plate mounting errors, out-of-round print sleeves, and debris before the plate ever gets to the press.

Whether you print and finish carton board or paper, the HEIDELBERG Intro gives you the highest throughput in the industry and meets your requirements with safety and precision. For medium or large order quantities, the HEIDELBERG Intro processes your work in a single pass from roll to roll or roll to die-cut at record speed.

Whether as an off-line machine or as an in-line solution in combination with the Intro or Boardmaster, the FCL flat-bed die-cutter provides maximum uptime and superior performance.