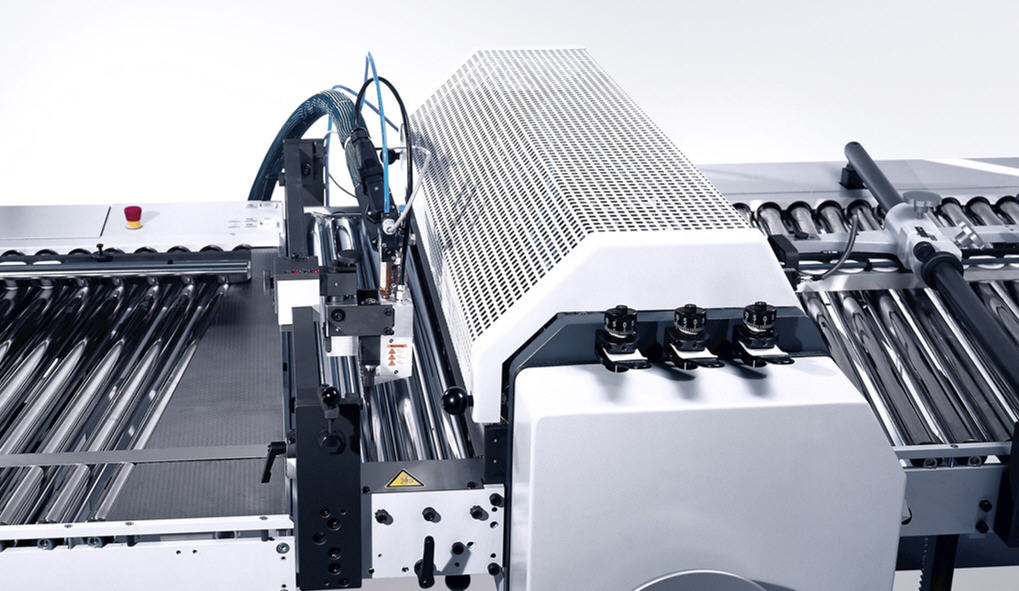

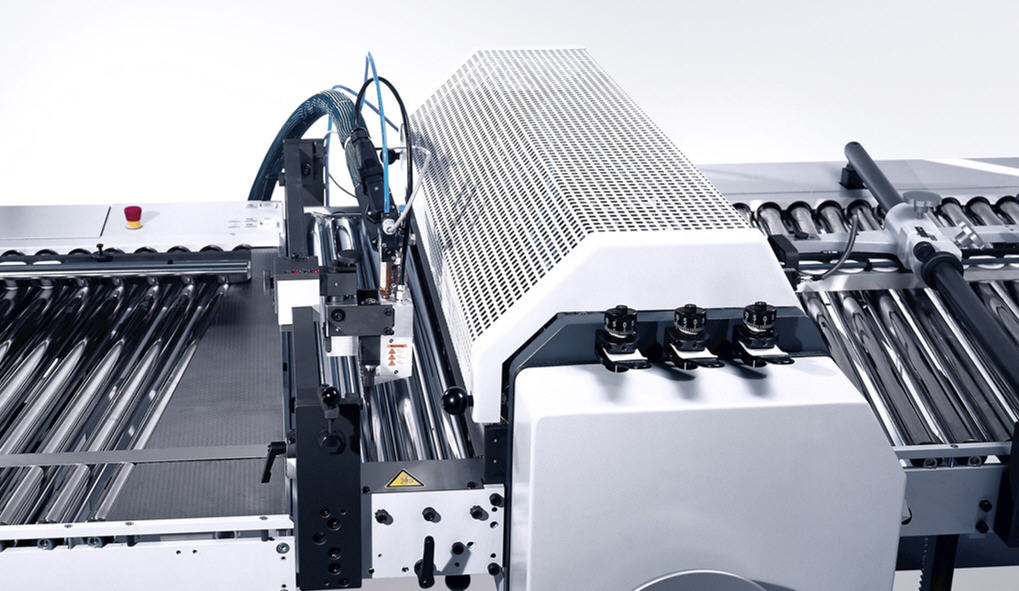

Slitter shaft Stahlfolder SSP

With the Stahlfolder SSP, you can master the very wide landscape formats frequently required for flyers precisely and efficiently. The scoring, slitting and perforating station can be combined with flat pile, round continuous and pallet feeders. The spines do not break after folding, even with high grammages and full-surface printed substrates, because the fold is meticulously creased. To make sure of this, the AirstreamTable reliably aligns the sheets with the rule, despite the very small contact surface in landscape formats. The unique ball-free system leaves no marks behind.

You can combine the Stahlfolder SSP – available in operating widths 56, 66 and 82 – with all downstream stations from the Stahlfolder folding machine and delivery range, irrespective of whether your configuration is manual or fully automated.

Slitter shaft Stahlfolder MWS

The Stahlfolder MWS is designed as a downstream station. Available with a choice of right or left-hand feeding and operating widths 66 and 82, the MWS can be flexibly combined with other modules from the Stahlfolder portfolio, as the infeed and exit height is infinitely adjustable. The Stahlfolder MWS is also equipped with three pairs of slitter shafts, and can perform the same processes as the Stahlfolder SSP.

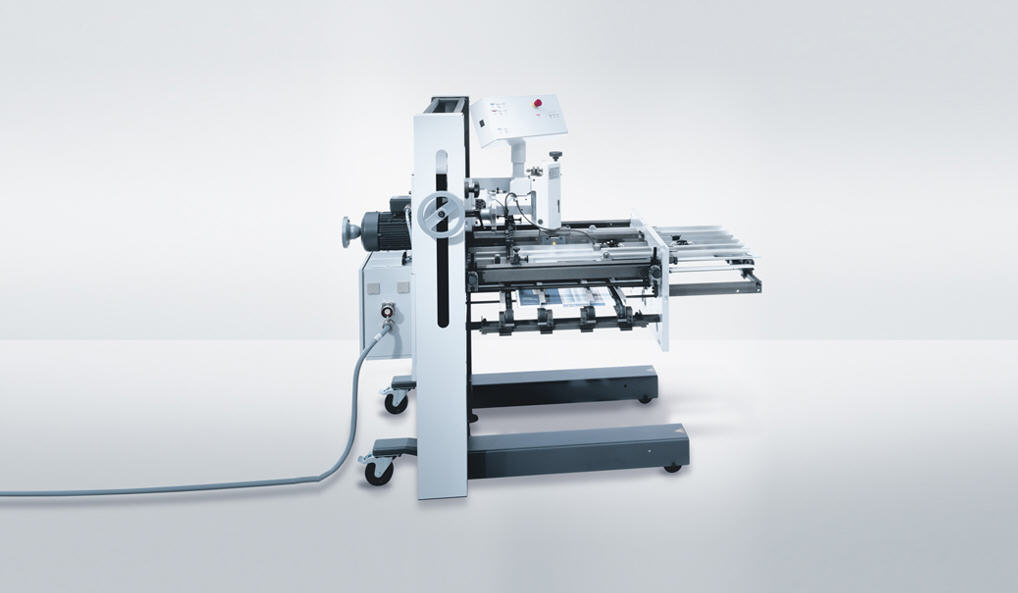

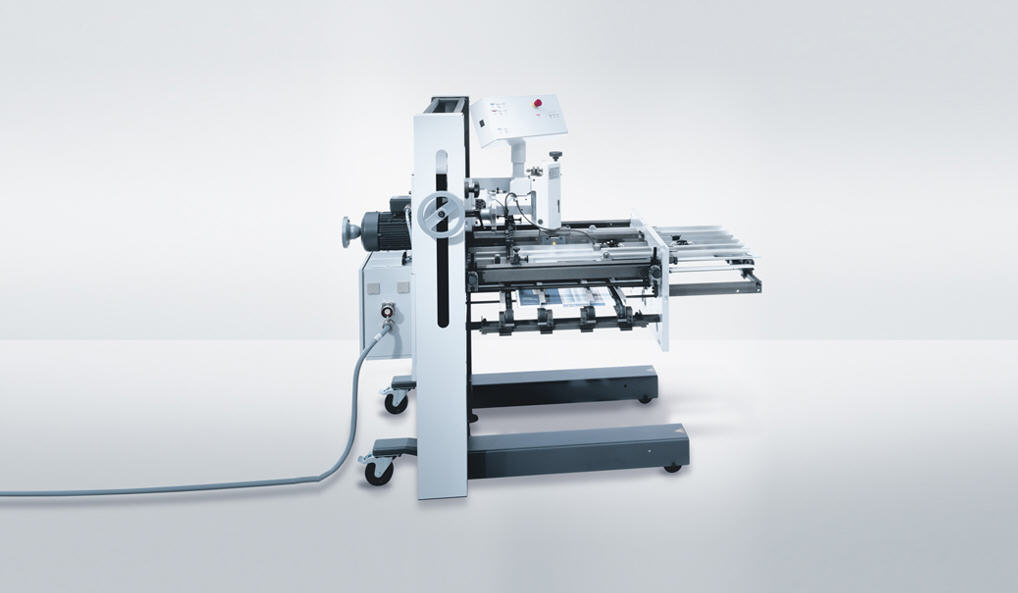

The mobile, height adjustable four-directional knife folding unit VFZ 52 supplements buckle plate folding machines as well as combination folding machines. When used as third unit of a buckle plate folding machine, an operator friendly U-configuration minimizes walking distances.

With low investment costs, additional folding schemes and particularly thick products become processible. The knife folding unit is swivel-mounted and allows you to offer folding schemes like the international quadruple fold.

It is common for binderies to require an extra folding unit to execute a final cross fold. The four-directional knife folding unit VF 66, with its independent drive and height adjustability, is particularly suited to meet this task.

Also glued and folded sheets can be processed using the VF 66 to produce final products. The optional rear mounted slitter shafts allow you to perform head and tail trimmings.

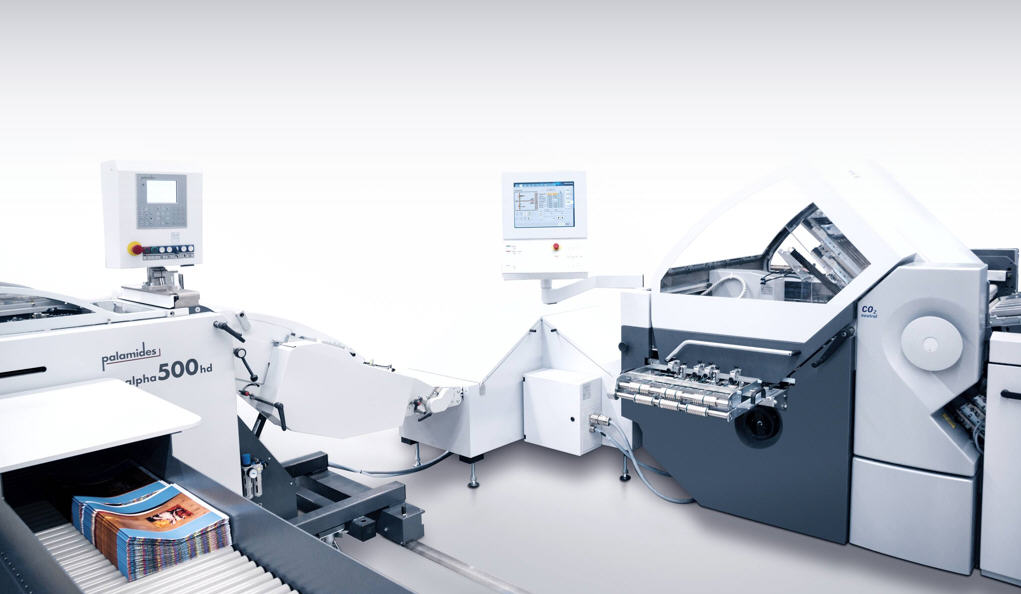

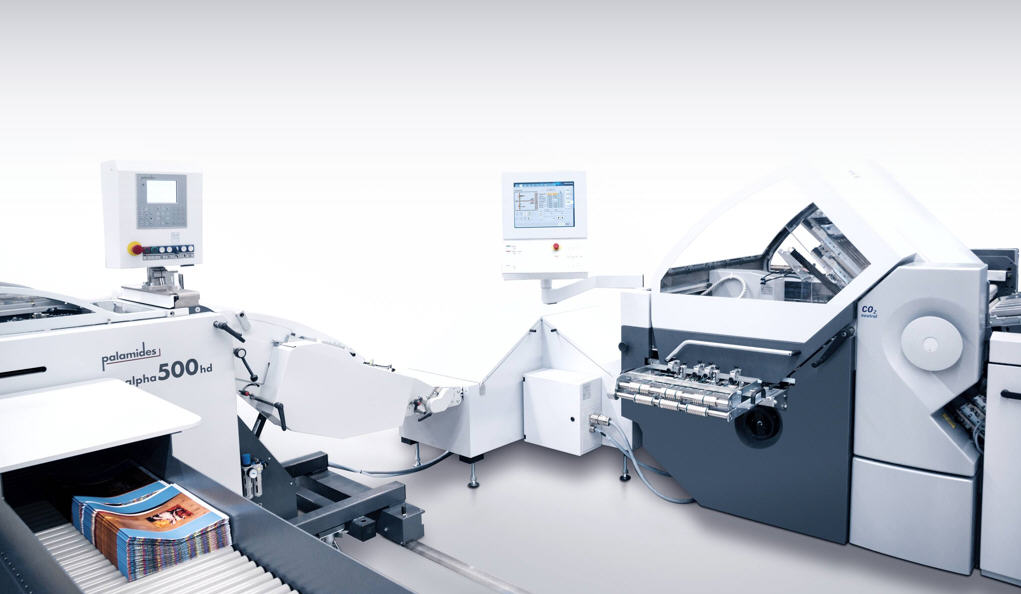

With the CombiCurve CC 41 corner deflector, you can finally save yourself the tedious and time-consuming task of repositioning the delivery and, in the case of bucket plate (TH) folding machines, also the need to move the third folding station. The palamides alpha hd stack delivery can be moved ergonomically and easily by hand on a rail system between the 16- and 8-page outfeed.

The Stahlfolder UES 66 transfer device is also used for the three-station buckle plate folding machine. The associated reduction in make-ready time is unique and of great importance in terms of productivity, especially for small and medium-sized print runs.

Reduce set-up times and handle even short-notice jobs flexibly, even with a buckle plate machine, without any great effort.

The combination of the Stahlfolder CombiCurve CC 41 and StackStar P in particular unleashes the full potential of the folding machine.