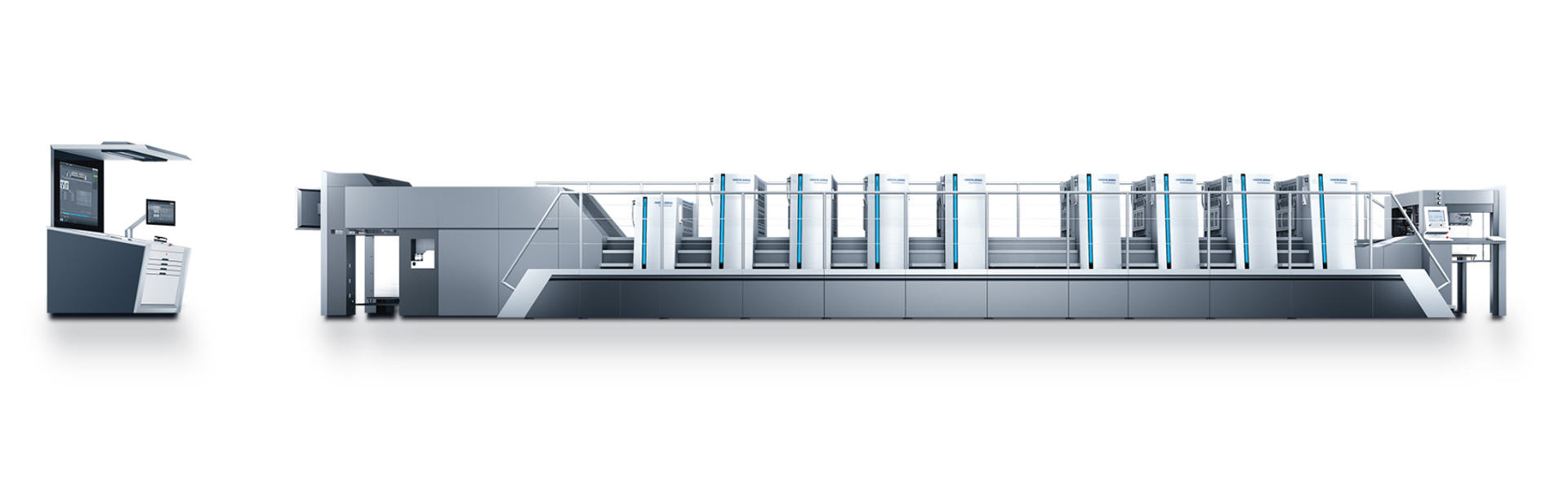

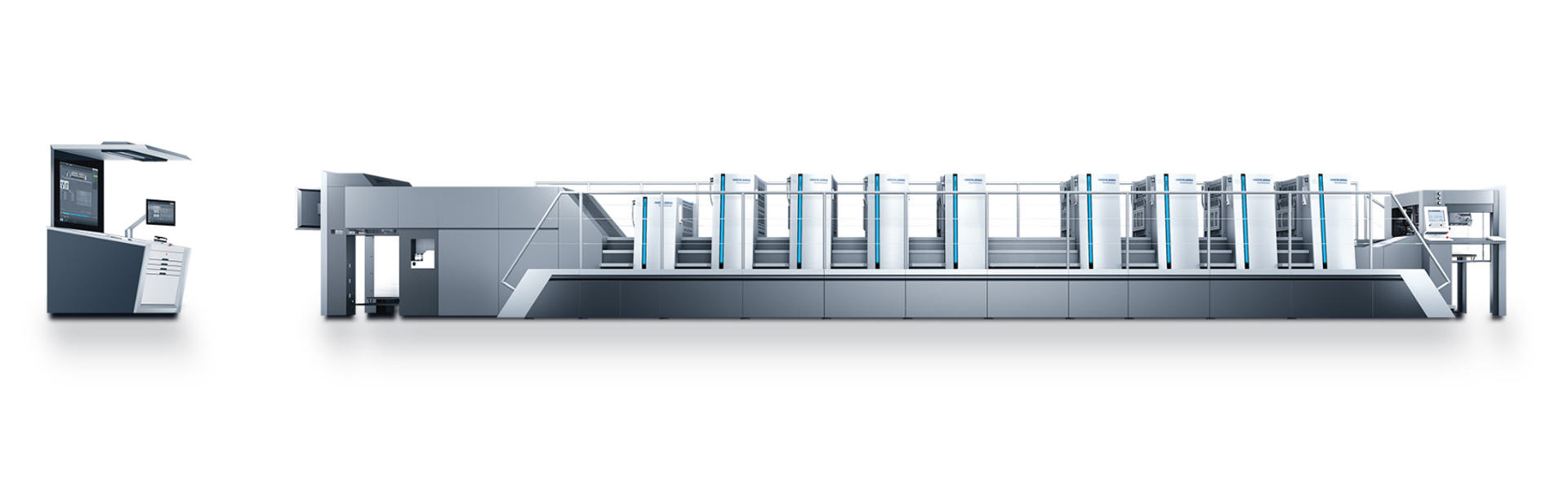

This future-oriented press in 50 × 70 format delivers high efficiency, productivity, and ease of operation.

With Push to Stop, the efficiency of print production (OEE) can be raised to a level that has been difficult to achieve in the past. The new Intellistart 3 assistance system revolutionizes your job changes with comprehensive, time-optimized automation. Push to Stop and the implementation of artificial intelligence offer you a unique user experience (UX): autonomous and navigated printing across the entire printing process. The new Intelliline can be used to visualize the respective machine states. Machine operation is now easier than ever – the new HEIDELBERG User Experience of the Speedmaster will inspire you.

The result is a machine that adapts to changing market requirements. Top quality with maximum availability – you can rely on that.

through reduction of process-dependent and operator-dependent downtimes – operator-independent performance through intelligent automation.

thanks to fully automated air settings when changing substrates using characteristic profiles.

through an increase in speed to 16,500 sheets per hour with straight presses.

Fully automatic application of Saphira roller protection liquid – in the Intellistart process.

The Speedmaster XL 75 is the perfect press for the following segments, depending on the customer-specific configurations:

To find your optimal configuration, please contact your local HEIDELBERG sales representative.