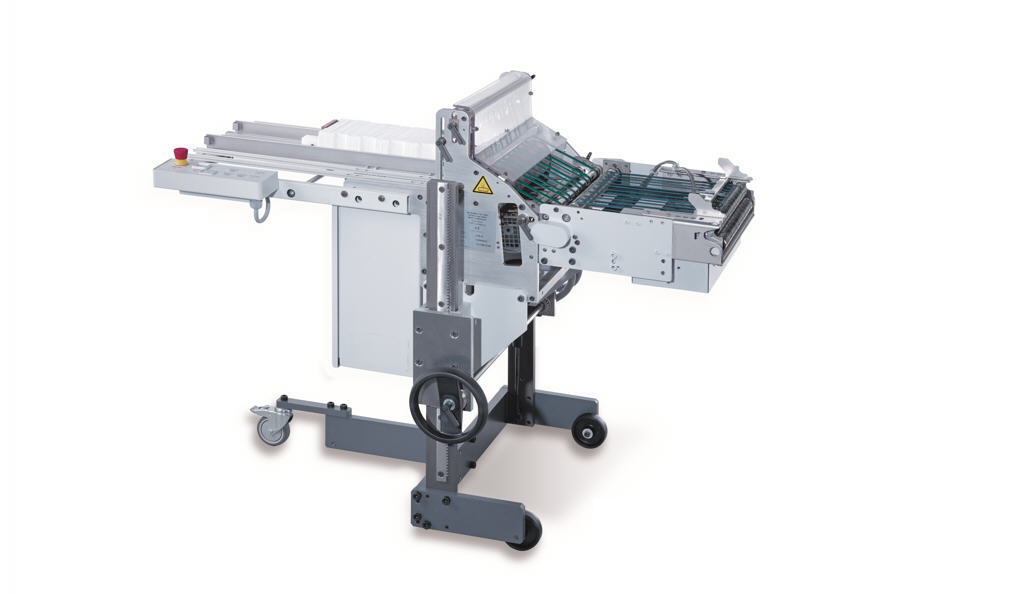

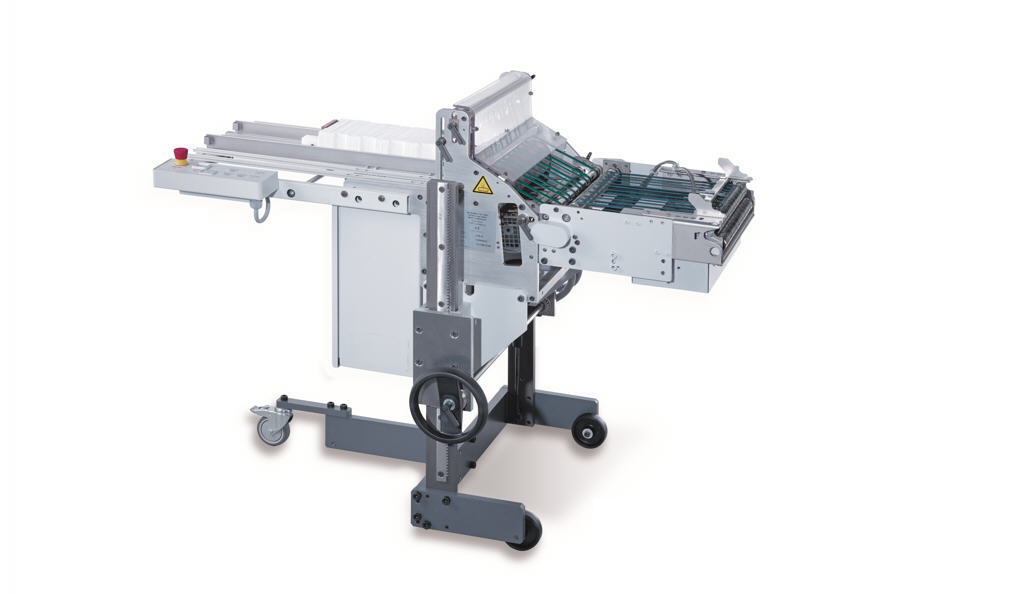

The small format delivery STA 40 is specially designed for small-sized products down to two centimeters final product length and four millimeters maximum product thickness. This makes it the ideal delivery for multiple folded packaging inserts, as used in the pharmaceutical industry.

The mobile delivery reliably prevents the folded products from bursting up again, because they are delivered upright, with the spine downwards against the vertical sprung stop. The integrated counting and marking function allows the lateral displacement of the folded products. Thus the operator can unload them in an exact amount into trays. With the optional extended delivery table, the buffering capacity of the delivery is increased, whereby a large number of thick products can be delivered. The continuously adjustable speed and infeed height allows combining the small format delivery STA 40 with all Stahlfolder folding machines. At this juncture, the most important machine functions can be controlled via the integrated control panel.

The stream deliveries SAF, SAL and SAK are universal systems to deliver single or multiple-ups and are capable of processing a wide range of formats, product thicknesses and shapes. The infeed height and the conveyor speed are adjustable precisely.

The SPH is a stream delivery with integrated pressing device. The pressing rollers deflate the air from the folded products and guarantee sharper folds. You can not only unload the products easier to the pallet, but offer your customers an excellent quality.

The conveyor belts guide the sheets through a pair of pressing rollers. With the integrated sheet monitoring and marking function you are able to unload an exact amount of products. The mobile stream delivery SPH 70 and SPH 100 with height adjustable infeed section are universally compatible with all Heidelberg Stahlfolder folding machines.

The horizontal stack delivery SBP is a delivery system with a high storage capacity for folded or bound products that is therefore particularly suitable for the processing of medium to large runs.

The horizontal stack delivery SBP 66 and SBP 86 allows you to deliver folded and bound products of larger runs efficiently. Even multiple-ups and delicate papers can be processed with ease. The integrated pressing unit increases the folding quality, and the height adjustable infeed makes the delivery combinable with all Stahlfolder folding machines. The most important machine functions can be controlled directly on the integrated control panel. This allows the operation of the entire machine with one person and increases your profitability.

Thanks to its high buffer capacity and the possibility of processing multiple ups, the Stahlfolder SBP is the right delivery for getting started in industrial signature production, and is perfect for combining with Stahlfolder TH/KH folding machines.

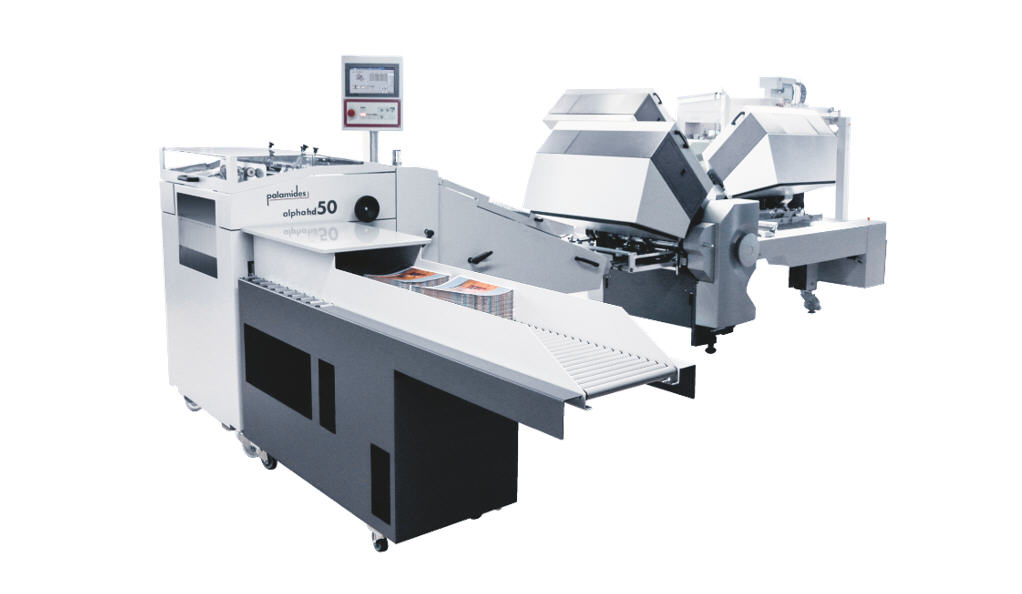

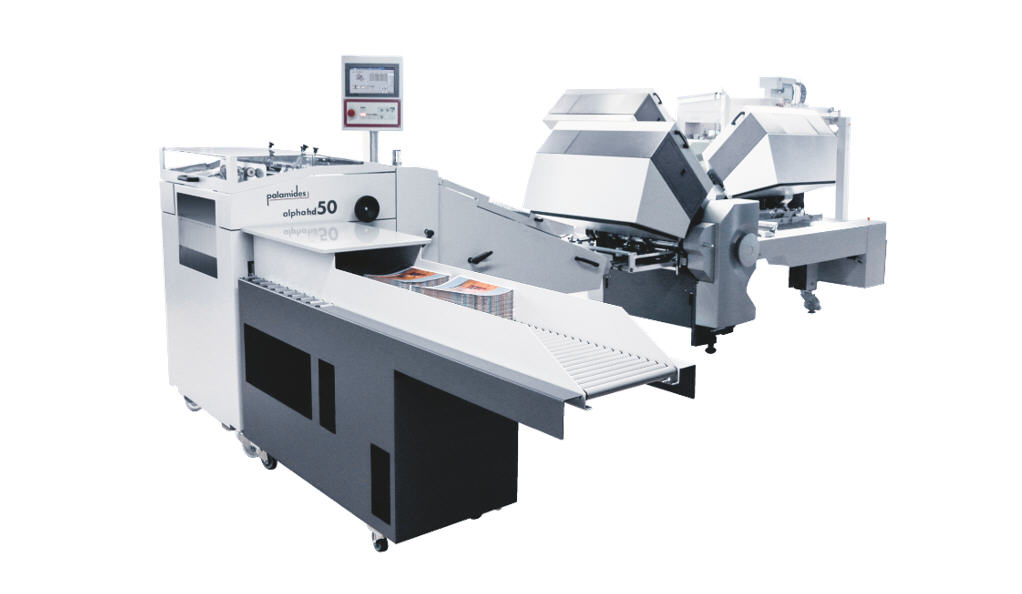

The palamides alpha hd is the perfect delivery for your industrialized and highly efficient signature production. This delivery generates exact piles and delivers mark-free products even if your folder runs with high capacity. This allows you to operate the entire system with one person only.

Advantages at a glance:

To increase the efficiency of the entire folding system, the palamides alpha hd can be combined with other units and options, such as the Push to Stop Function for autonomous signature change, the CombiCurve CC 41 , or the autonomous stacking system StackStar P.

The system is therefore suitable both for long runs and small runs in combination with folding machines in the Peak Performance class, such as the Stahlfolder TH/KH 82-P and Stahlfolder TX 96.

Stahlfolder folding machines of the latest generation are in no way inferior to printing presses where performance is concerned. In order to fully exploit the potential of the folding machines, efficient delivery systems to relieve the operator are essential. This is what the palamides delta delivery aims for.

The palamides delta deliveries are used whenever workflows need to be streamlined. delta deliveries perform steps such as pressing, stacking, jogging and banding. The banding process itself is not important, however, but simply the means to an end: the entire folding system can be operated by one person – even with a very high output. The banderole keeps the packs stable so they can be deposited more quickly. For production with multiple repeats, different banderoles can be used to help distinguish the products more easily. This makes the palamides delta the perfect delivery not just for highly productive folding machines, but also for saddlestitchers or mailing systems. The fully automated delivery enables speedy makeready for every application.