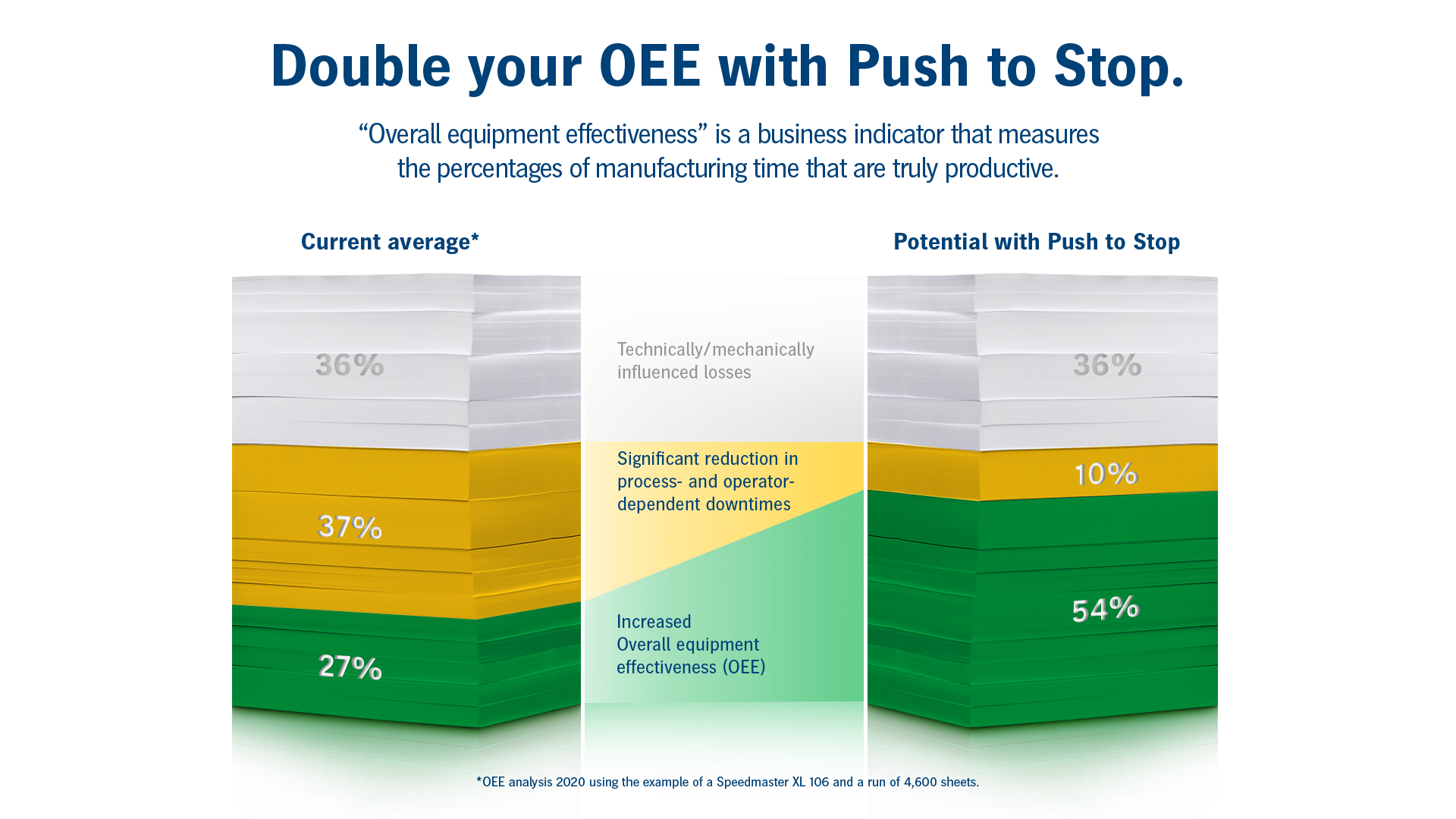

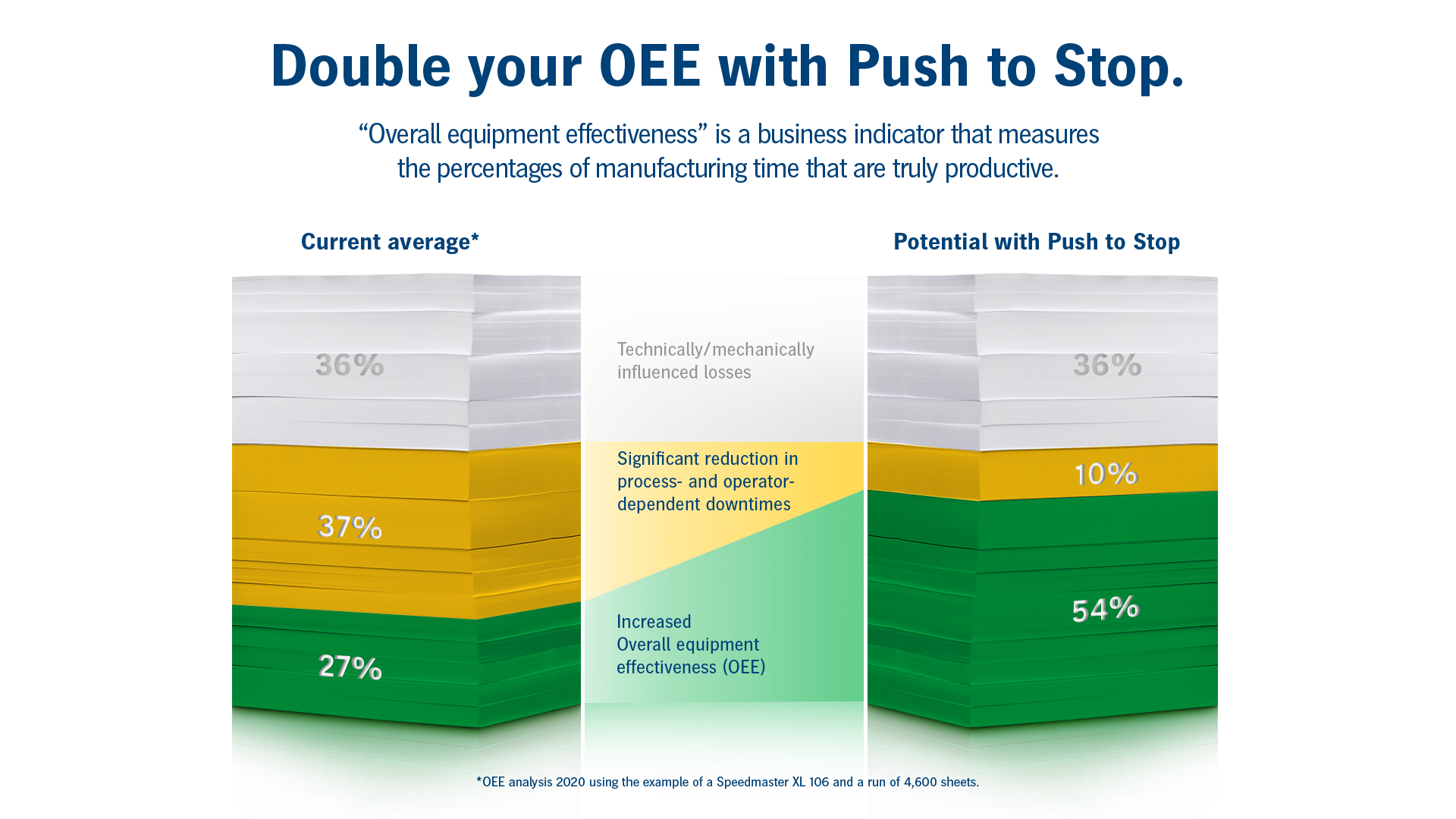

Overall equipment effectiveness (OEE) is an important key performance indicator for assessing how effectively a production system is operated in practice. It is made up of the factors of availability, performance, and quality.

The average OEE across all format classes is currently around 20 percent, and even the Speedmaster XL 106 from the Push to Stop generation, with an average OEE of 27 percent, still offers considerable improvement potential, since the OEE that can realistically be achieved is much higher.

This is proven by Speedmaster presses operating with an OEE of 50 percent and up. The average productivity is expected to double in the coming years.

With up to 90 million printed sheets a year, the first Speedmaster users are already showing what is possible.

In order to increase the OEE of the machines, existing improvement potential must be activated.

Around half of this potential is tied to technical aspects (gray bar in graphic). However, technical improvements will not necessarily result in success – only if the organizational aspects are improved at the same time.

The other half of the potential relates to processes and operators (yellow bar in graphic).

This is precisely where Heidelberg concentrates its activities.

Improvements that act on the yellow bar, in other words on the processes and operators, have a direct influence on the OEE. This is where the greatest potential lies.

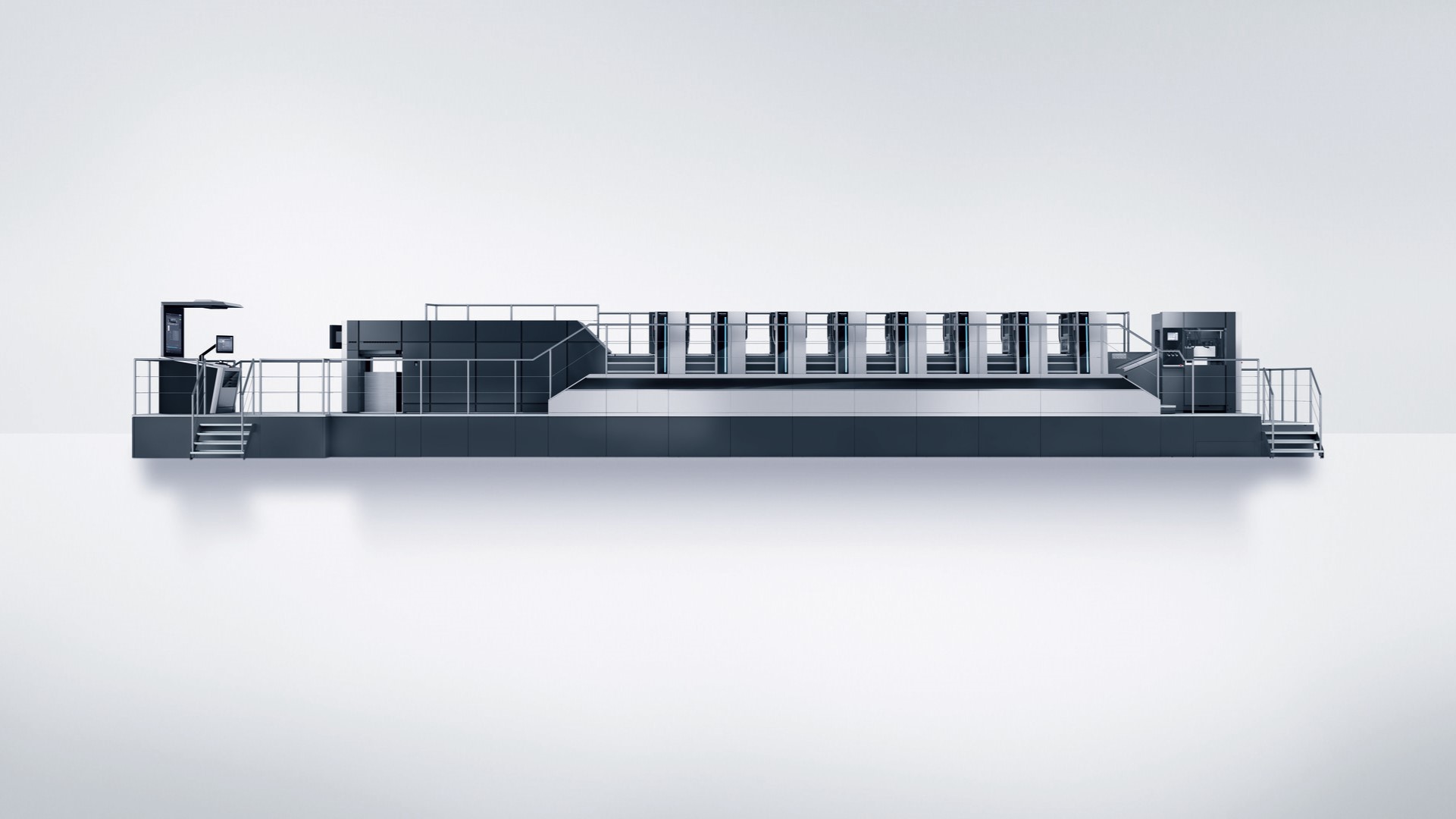

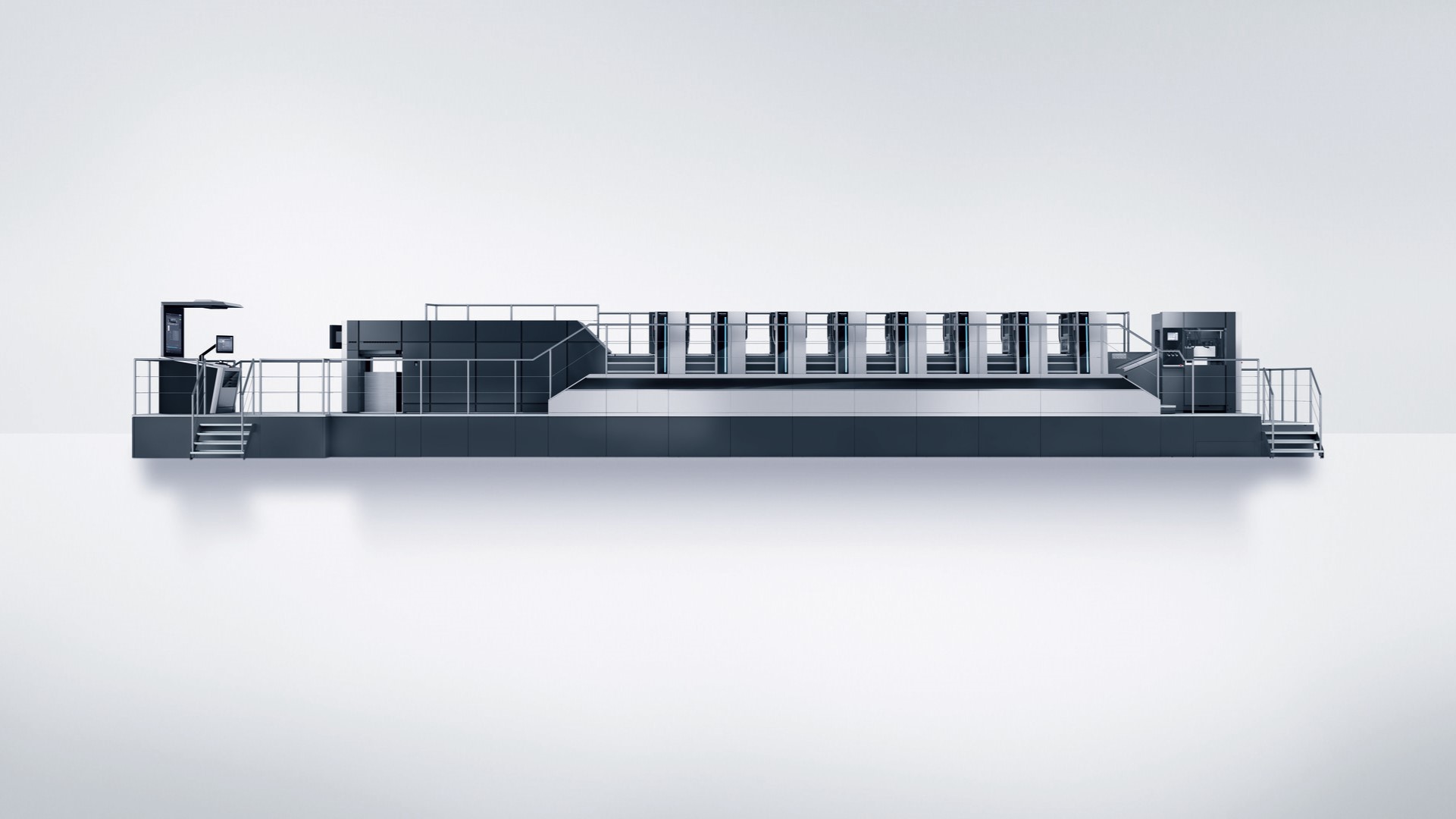

With Push to Stop, more extensive process automation, and intelligent assistance systems, the Speedmaster presses enable comprehensive navigated and autonomous printing.

The machine’s intelligence minimizes the operator’s influence on performance. Productivity is increased, processes are sped up, and become plannable and reproducible.

The operator is navigated through the processes at a modern and attractive workstation, and in this way is better equipped to handle the greatly increased day-today requirements.

Push to Stop powered by AI on a new level – for optimized overall equipment effectiveness on all Speedmaster models.