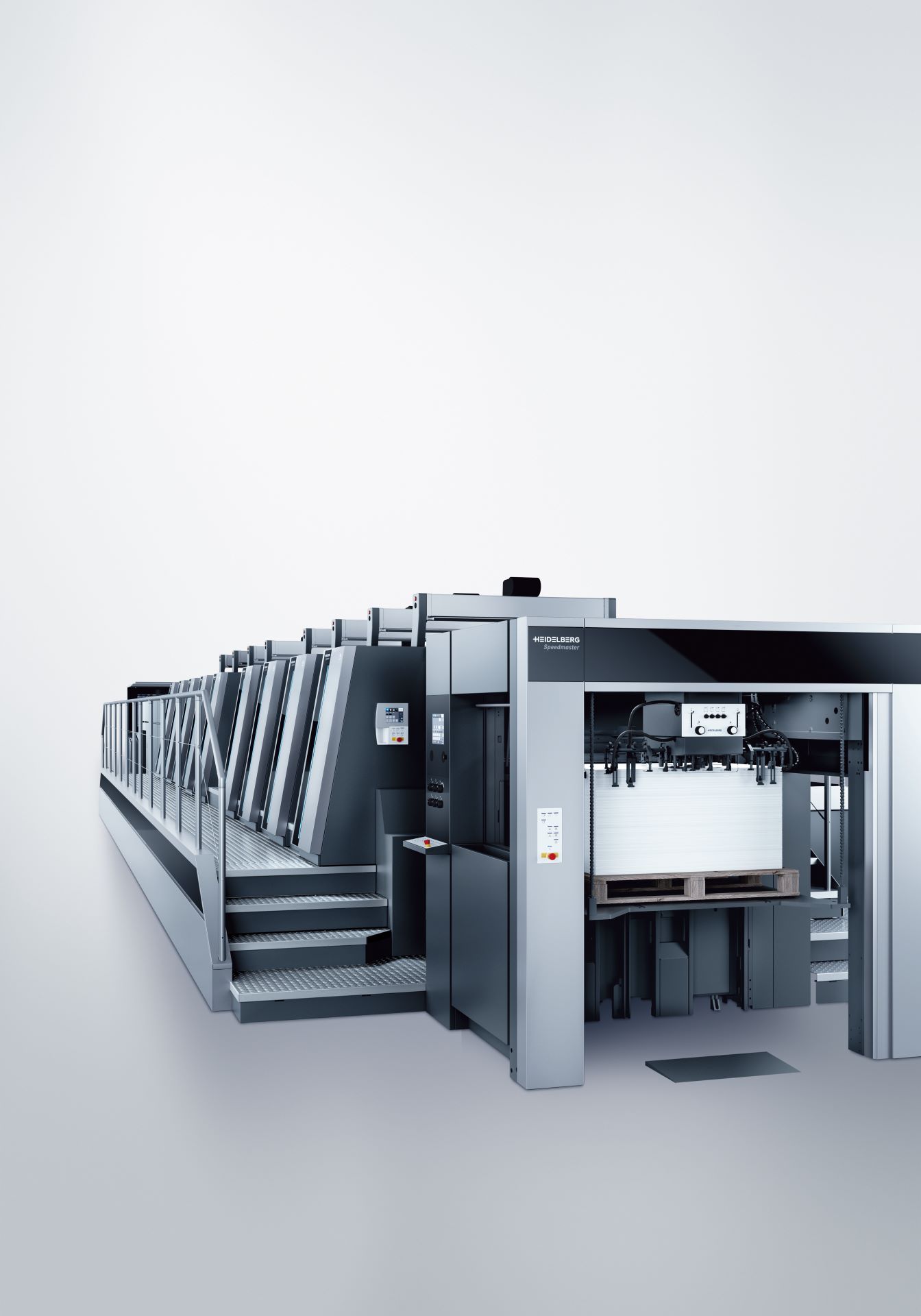

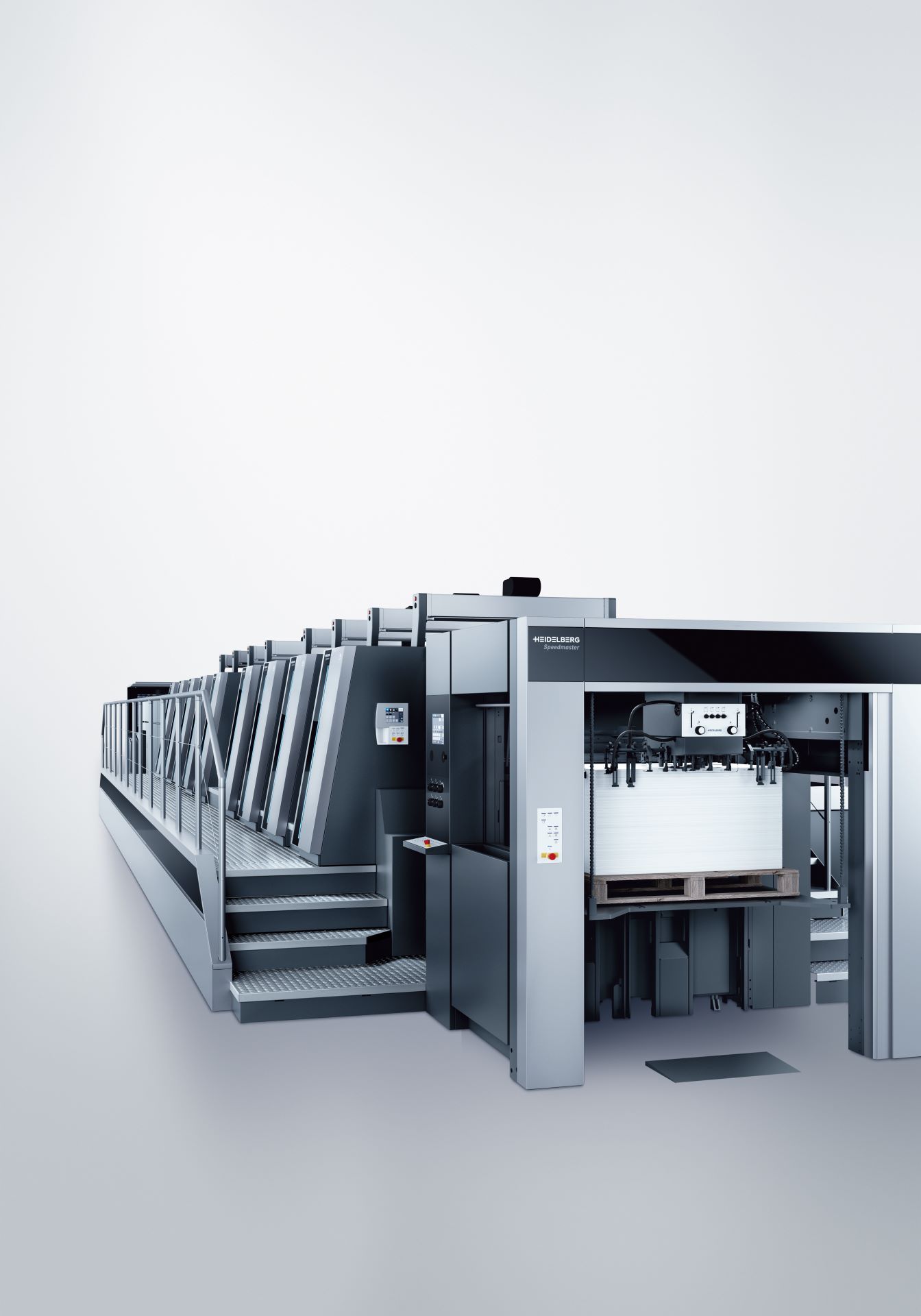

The features or assistance systems with artificial intelligence embedded in Speedmaster presses are based on intelligent algorithms that are able to configure complex production parameters automatically. Previously, these had to be defined or set manually by the operator.

This is how artificial intelligence works: During production, settings and quality measurements are first collected and then automatically evaluated. Regular data patterns are identified and their effect on the production result is learned. The insights are used to optimize the efficiency and quality of upcoming production.

The factory-set air presetting values for the fully automatic, substrate-dependent presetting and speed compensation have been further optimized. To this end, an autonomous process optimization was generated from over 600,000 print jobs using intelligent algorithms. The result - air preset values and optimized speed compensation enable an increase in productivity of up to five percent. In addition, the factory-set air preset values can be easily expanded with individual values thanks to Air Assistant.

In conjunction with a Prinect color measuring system (e.g. Prinect Inpress Control 3), the Color Assistant Pro software enables fully automatic and continuous optimization of ink presetting on the Speedmaster. As a result, absolute precision is achieved in ink metering. The intelligent software algorithm uses the measured values from the Prinect color measurement system to check whether the ink presetting can be improved and adjusts it fully automatically. The color presetting characteristics are therefore always up to date. Film wear is also compensated for automatically and the optimum time for a film change is monitored and displayed. The Color Assistant Pro avoids errors caused by manual handling and achieves increased, operator-independent performance. This automatically creates the perfect conditions for fast set-up with minimal waste. Precise color presetting makes all the difference and run production can often start before the 60th sheet.

The innovative Powder Assistant achieves consistent print quality with less powder usage and fewer powder-related disruptions in finishing. The powder setting is intelligent and data-based, as the unique, sophisticated tool independently selects the optimum presetting depending on the substrate and actual ink coverage. The result: avoidance of unnecessarily high powder loads in the pressroom, reduced soiling on the machine and therefore shorter cleaning times.

The Wash Assistant feature permits intelligent and automatic selection of the right wash program (short, standard or intensive) on the basis of the press status for the blanket, impression cylinder and inking unit washing systems. The degree of soiling left behind in the printing units by the previous printing conditions is continuously analyzed throughout the entire production process to ensure that the right washing program is selected. Customer-specific washing programs can also be used for this purpose and assigned to a degree of soiling. When automatic mode is switched on, the selection of the correct wash program in Intellistart 3 (for the current job change) or in Directstart (during production) is constantly adapted to the current status of the machine. The Wash Assistant enables shorter set-up times with suitable wash results and contributes to significantly lower consumption of washcloth and detergent.

Intellistart 3 defines all the steps required for the job change without any operator intervention and provides maximum transparency across all active and queued processes. What makes Intellistart 3 unique is that it compares the current press setting with the settings required for the next job, and the information obtained is used to automatically generate a job change program. Intellistart 3 thus automatically generates all the steps required for the intelligent job change in the form of a dynamic and process-oriented process list. Overall, operating steps are reduced by 70%, job changes become more effective and 100% transparent thanks to Intelliguide.

Sophisticated subjects in high-value packaging and high-quality commercial jobs require specific printing knowledge in order to achieve the target quality as efficiently as possible. Hycolor Assistant automatically recommends the optimal setting of the ink/dampening unit when the job is accepted. For this purpose, preview images of the respective print job are analyzed and calculated in advance. The AI-based Hycolor Assistant in conjunction with Hycolor XL saves up to 25% set-up waste thanks to optimized presetting of the paint dampening unit before the first sheet goes into the machine.

Available as an app in the HEIDELBERG Customer Portal, the powerful AI tool continuously analyzes print shop and machine data and automatically recommends solutions where necessary, similar to a human advisor. PAT detects deviations and offers suggestions for optimization. Implementing the recommendations saves time and waste, improves press performance and thus leads to increased productivity. PAT also provides easy-to-understand charts and insights that highlight potential savings.