After all, this method doesn’t just create striking effects on packaging – it is also much faster, more flexible and more cost-effective than hot foil. Cold foil is also more suitable for recycling than metalized film-laminated PET packaging, as the aluminum pigments that transfer onto the substrate are easier to remove in the disposal process.

This is due to insufficient process stability, which is an irritating problem for print shops and their customers. FoilStar Cure from Heidelberg primarily resolves this issue by using dedicated LED UV cold foil adhesives and inks and dryers. Heidelberg has optimized web guidance on the FoilStar, which can be retrofitted to any appropriately configured press, so that the foil web stays on the impression cylinder for longer.

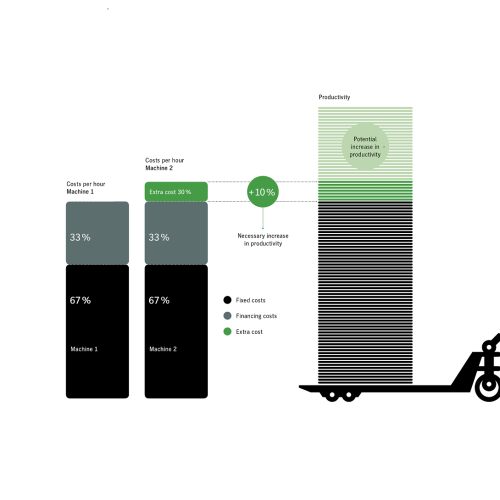

Investing in a new press has consequences for the entire business, so careful selection is vital. In particular, it is important to take a close look at the purchase price...

When it comes to the subscription model, Lensing Druck is one of the pioneers. The decision was a smart move, remarks Robert Dembinski, Managing Director of Lensing Druck, in this interview.

HEIDELBERG News features articles about industry trends, new technologies, print applications as well as success stories of print shops from around the world.