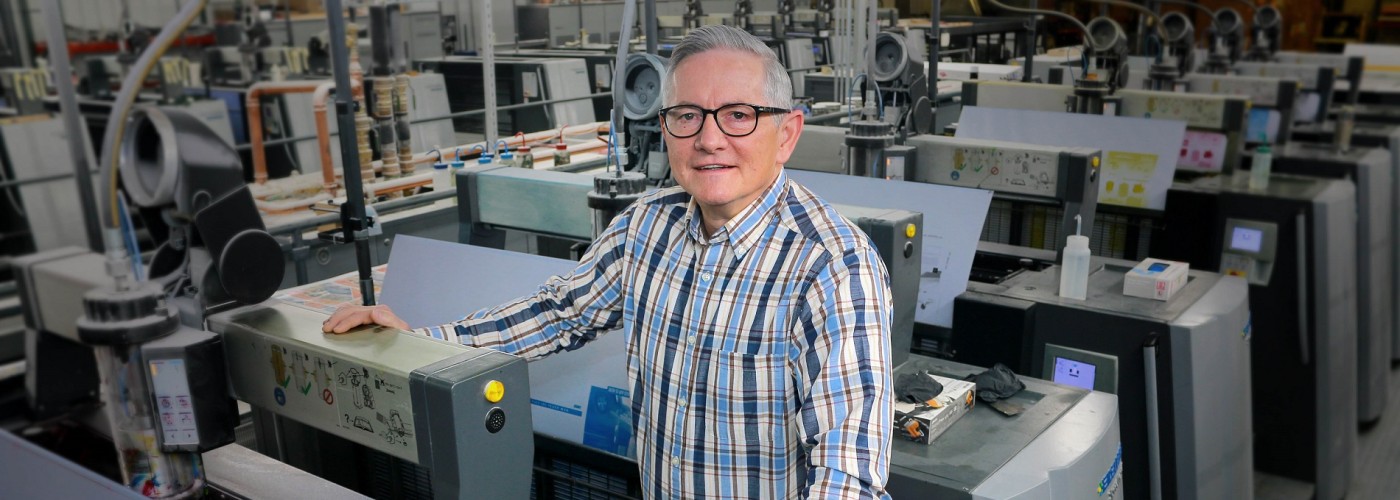

“We have always been a HEIDELBERG house and know exactly what can be achieved using their presses. There is no doubt in our minds that the Speedmaster XL 106 will do the job, and what’s more, it’ll do it more efficiently than we do now.”

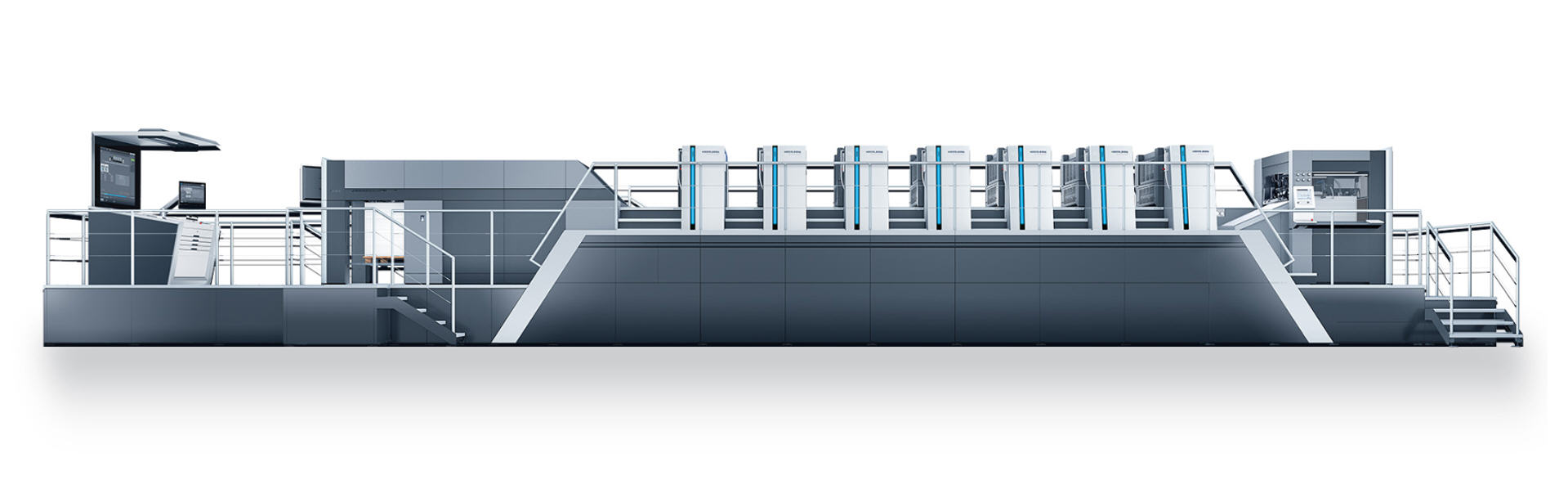

Marquis' new Speedmaster XL 106, equipped with LED UV, inline CutStar sheeter, and new Plate to Gallery logistics, is part of the company’s greater plan for continued growth – aiming to double its business within the next ten years.

“We knew every sheet running through the current presses was costing a lot more than a sheet running through a more automated technology." Based on its superior experience with the Speedmaster perfectors at its headquarters in Jefferson City, Modern Litho decided to replace three of the four older presses in Kansas City with a new Speedmaster XL 106-8P+L, said Jim Tomblinson, Modern Litho’s Chief Operating Officer.

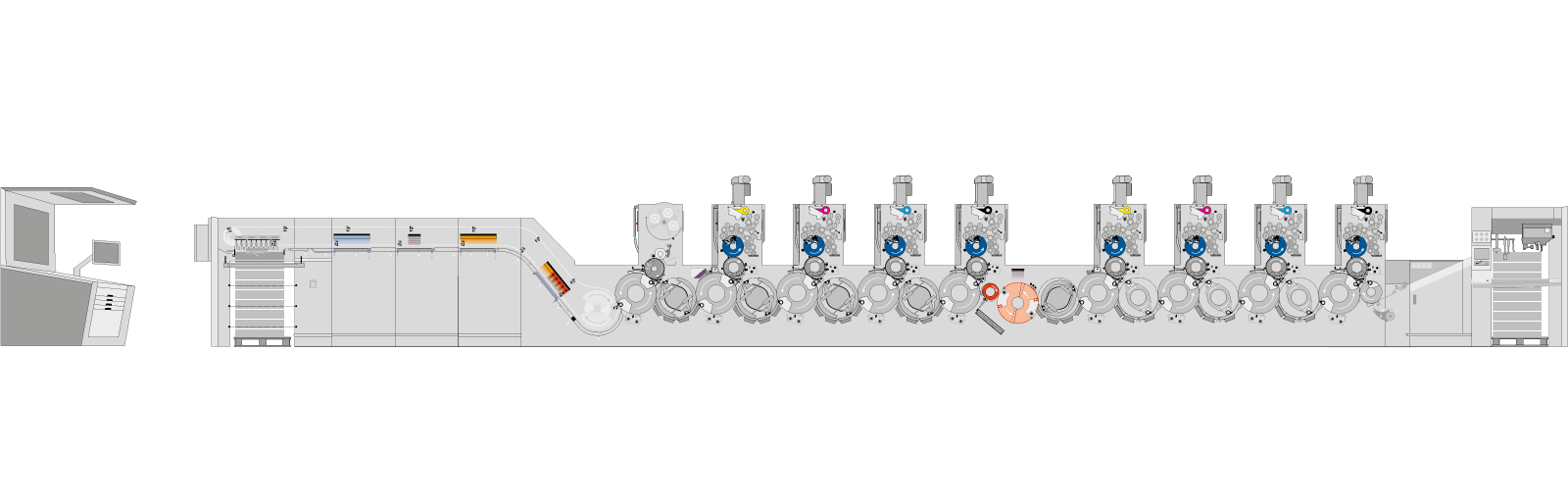

A new Speedmaster XL 106 with 12 printing units and a perfecting device to service the growing and popular K-Pop industry.