Unlock the secrets behind the exceptional performance of Speedmaster presses. Discover how the unparalleled quality of their components, our stringent testing methods, and sustainable manufacturing processes can contribute to the success of your printing business.

To achieve unrivaled performance, all Speedmaster presses are equipped with as many automatic processes as possible and integrated into an end-to-end workflow from job receipt to shipping. In addition, intelligent assistants and user-friendly operation reduce sources of error and make working on our Speedmaster presses an enjoyable experience.

Keeping the color quality high and consistent is the backbone of successful print production. Our Prinect color management systems are all directly connected with our Speedmaster presses to reach the match between proof and print fast and easy. Time consuming makereadies as well as start-up waste are reduced resulting in higher profits.

A Speedmaster is a considerable investment that should turn into profit as quickly as possible. This can only be achieved if it can exploit its maximum potential or, in other words, if fast job changes from the last to the first good sheet are stable and highly automated. We can measure how effectively a production system is actually operated by means of overall equipment effectiveness.

The present level of technology would not have been reached without human intervention. Heidelberg employs many young talents in order to keep all the processes that bring a Speedmaster to life up to dateand also develop them further.

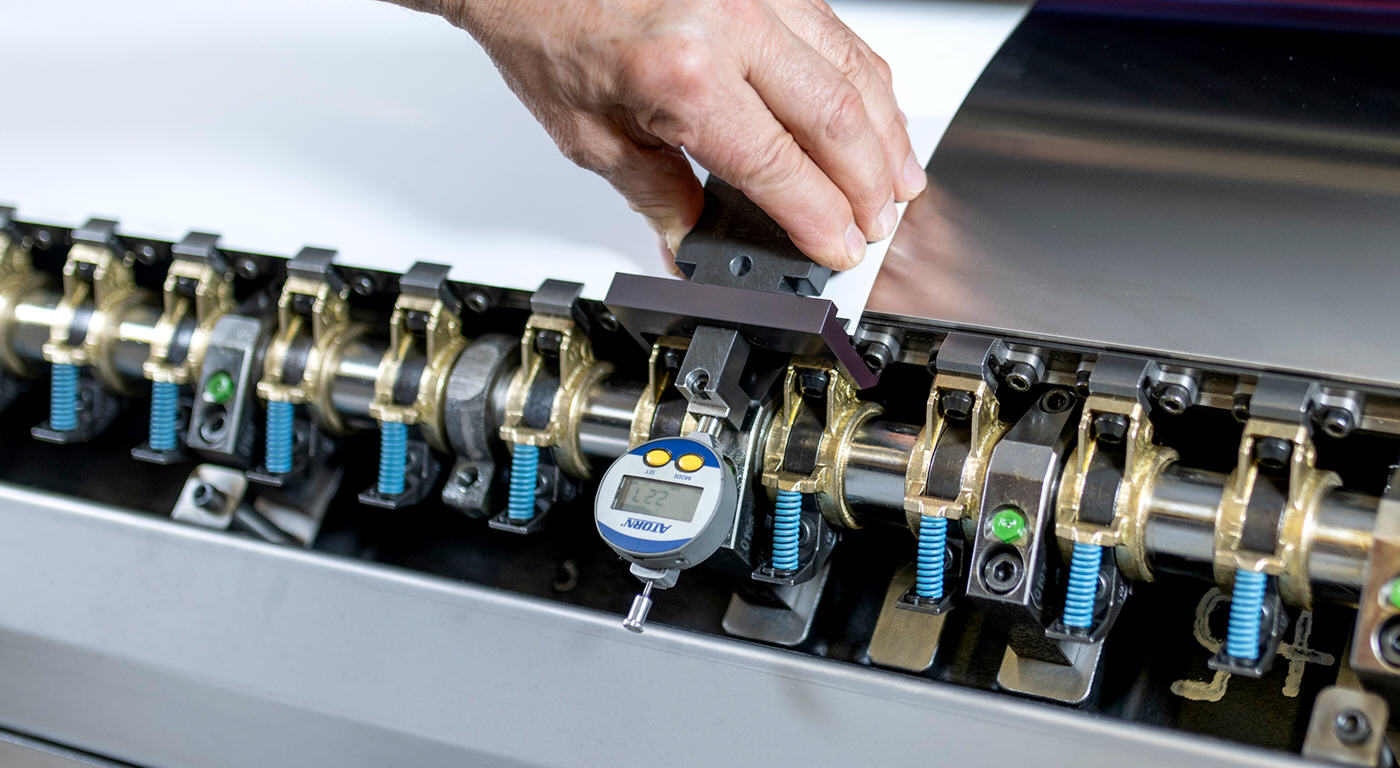

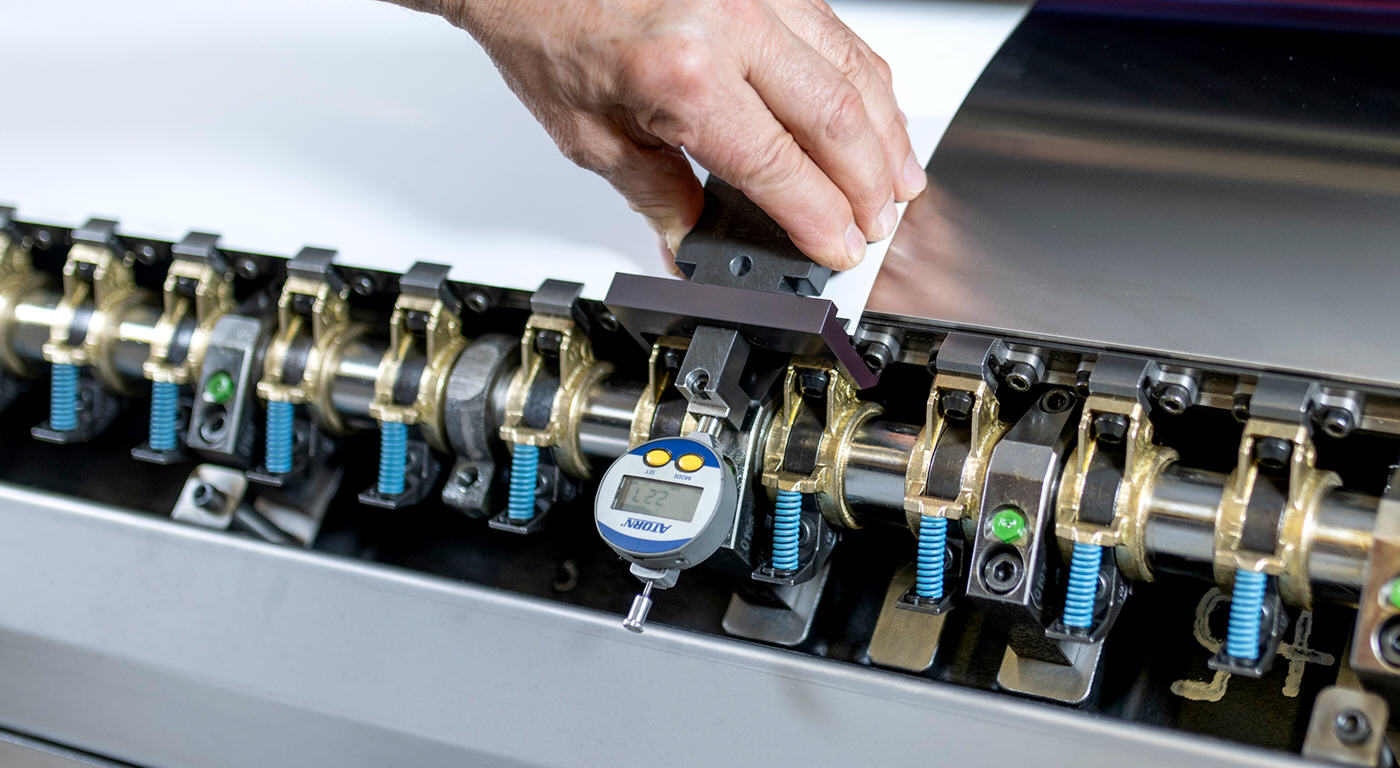

The highest quality requirements are continuously optimized, monitored, and combined with the latest technology in our process chain. In this way, the highest performance requirements are met, and maximum process accuracy and durability are achieved.

An example of this is our patented PLP pulsed laser process, which is used in the in-house production of anilox rollers for coating units, anilox fountain rollers, and in our Anicolor machines.

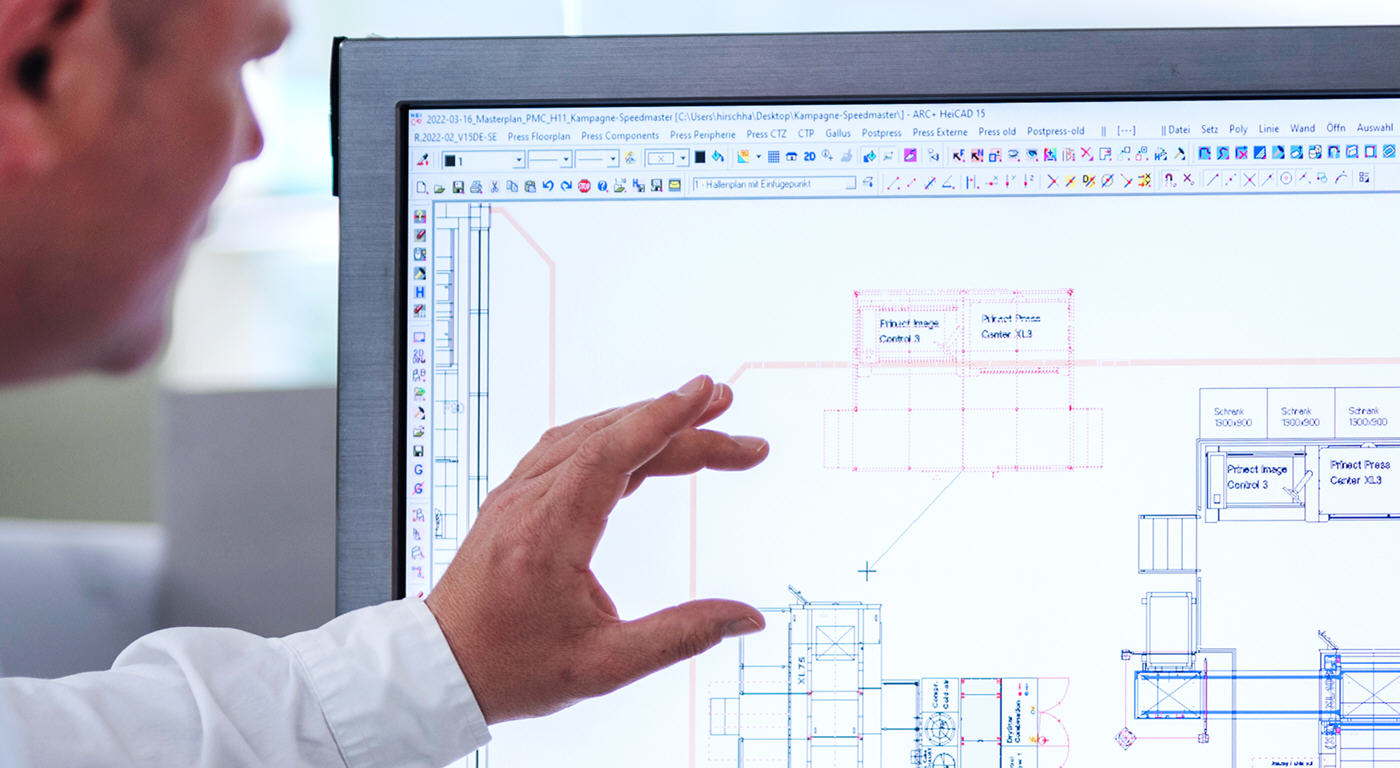

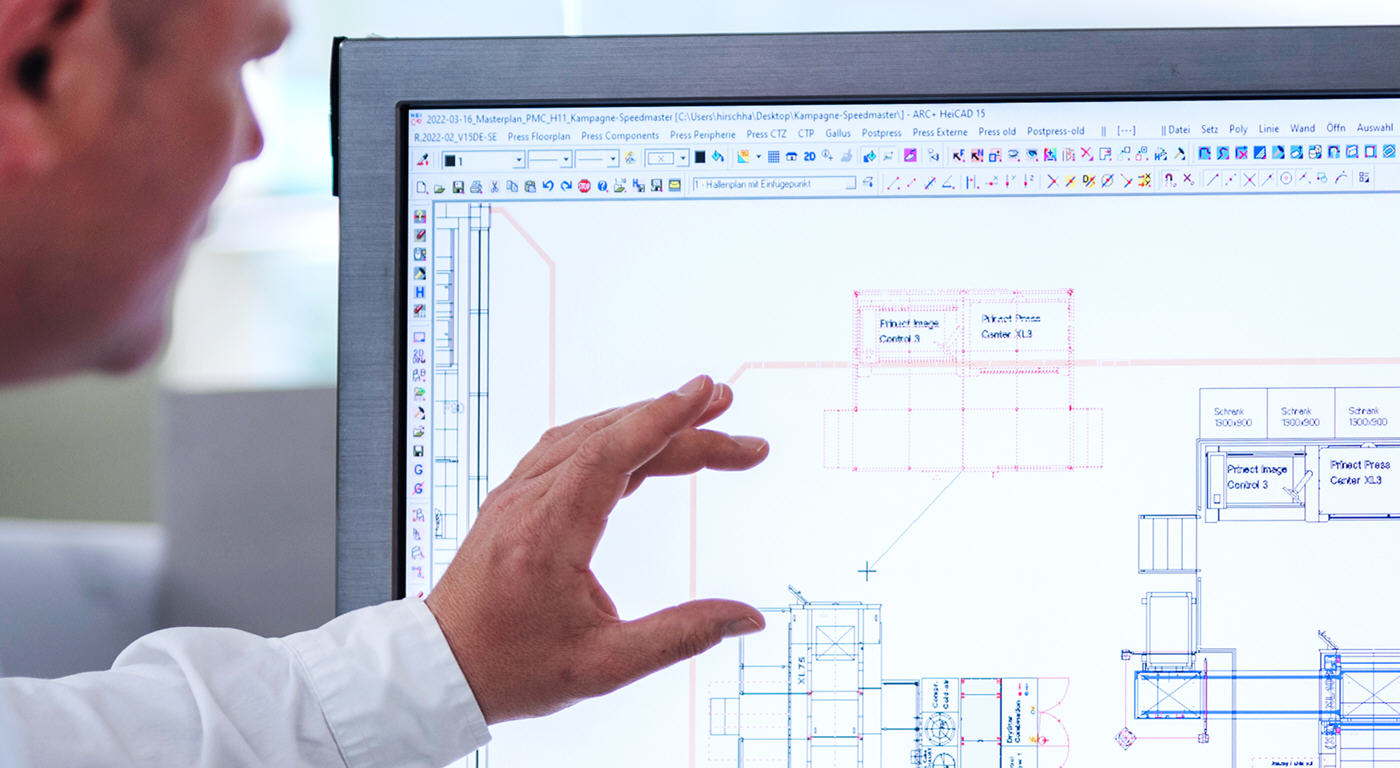

Working closely with you, our colleagues from Heidelberg Planned Service ensure that your new Speedmaster fits perfectly into its new environment.

Every critical detail of planning, positioning, space and structural requirements, cooling and exhaust conditions, as well as power supply, are determined in advance to ensure the efficient installation of your machine.

After the installation is complete, the quality of your machine will be checked again and if you want us to carry out further tests, our experts will be happy to help you.

Everyday stable production in your print shop with as little effort as possible – that’s what every Speedmaster is made for.

Our wide range of services – from technicians who are, of course, also on site, via online offerings and AI-supported solutions to our scalable contract models - additionally secures your investment and reduces downtimes to a minimum.

The Maintenance Manager is just one component of what we offer. Combined with other services, it saves time, money, and unnecessary fuss.

The Heidelberg owned foundry in Amstetten turns appr. 86,000 metric tons of cast iron per year into high precision parts. Perfectly tuned production processes ensure that all heavy metal parts - from the smallest to the biggest gear - will add to smooth print production.

Machine guards, cylinders, gears and countless other essential parts are designed and made in close cooperation between R&D and manufacturing.

Everything has to fit perfectly down to the last millimeter to contribute to the highest quality output possible.

Before a machine is delivered to our customers we also test the details for precision and quality to have the paper travel smoothly through each Speedmaster.

Making printing environmentally friendly is one of important initiatives. Speedmaster presses are a great example of how our technology can contribute to a better future and a cleaner planet. The production of all our machine models can be CO2-compensated. This is another reason why they are a great investment, also for the reputation of your company.

The Speedmaster line is designed and engineered in close partnership with our customers to get the best possible results for full day-to-day operation. The two main benefits are:

Do you have any special demand for your print shop?

Each Speedmaster comes “ready to print” - presettings and characteristic curves that have been developed and extensively tested in our R&D facilities. These automatically set functions make the press ready to start production in no time. We are turning Big Data, Artificial Intelligence, Cloud Computing, and Business Analytics into measurable increased success.

Transform your print shop into a digital one to achieve measurable success.

To really appreciate a Speedmaster, we must look “into its soul”. Each model has numerous novel features and functions that have never been implemented before by anyone in the printing industry. These innovations are developed to serve today’s demands and get print shops around the world ready for tomorrow’s challenges.

Get ahead of the industry with the help of cutting-edge technology.