What is this trend for using cold transfer techniques on labels all about?

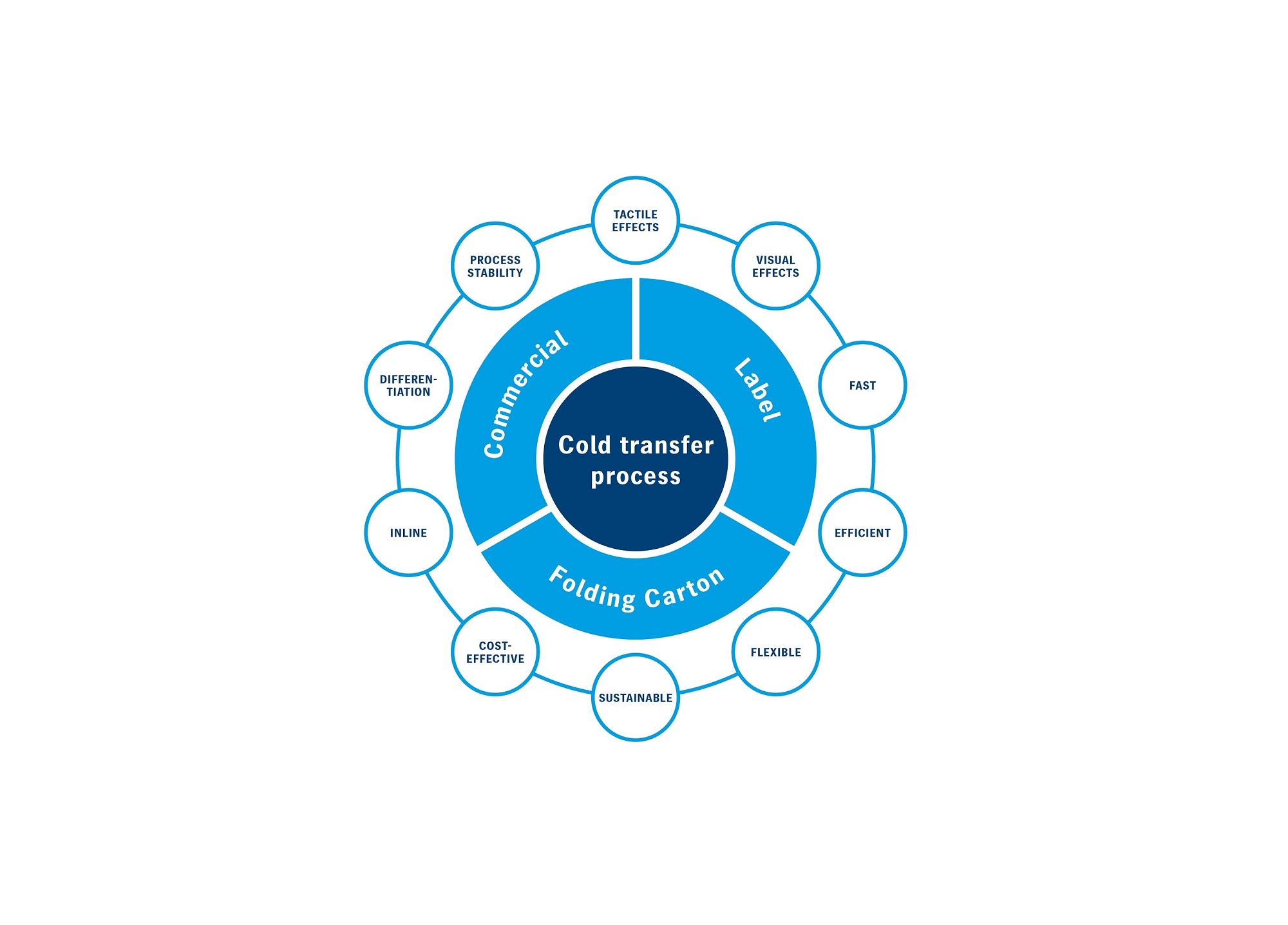

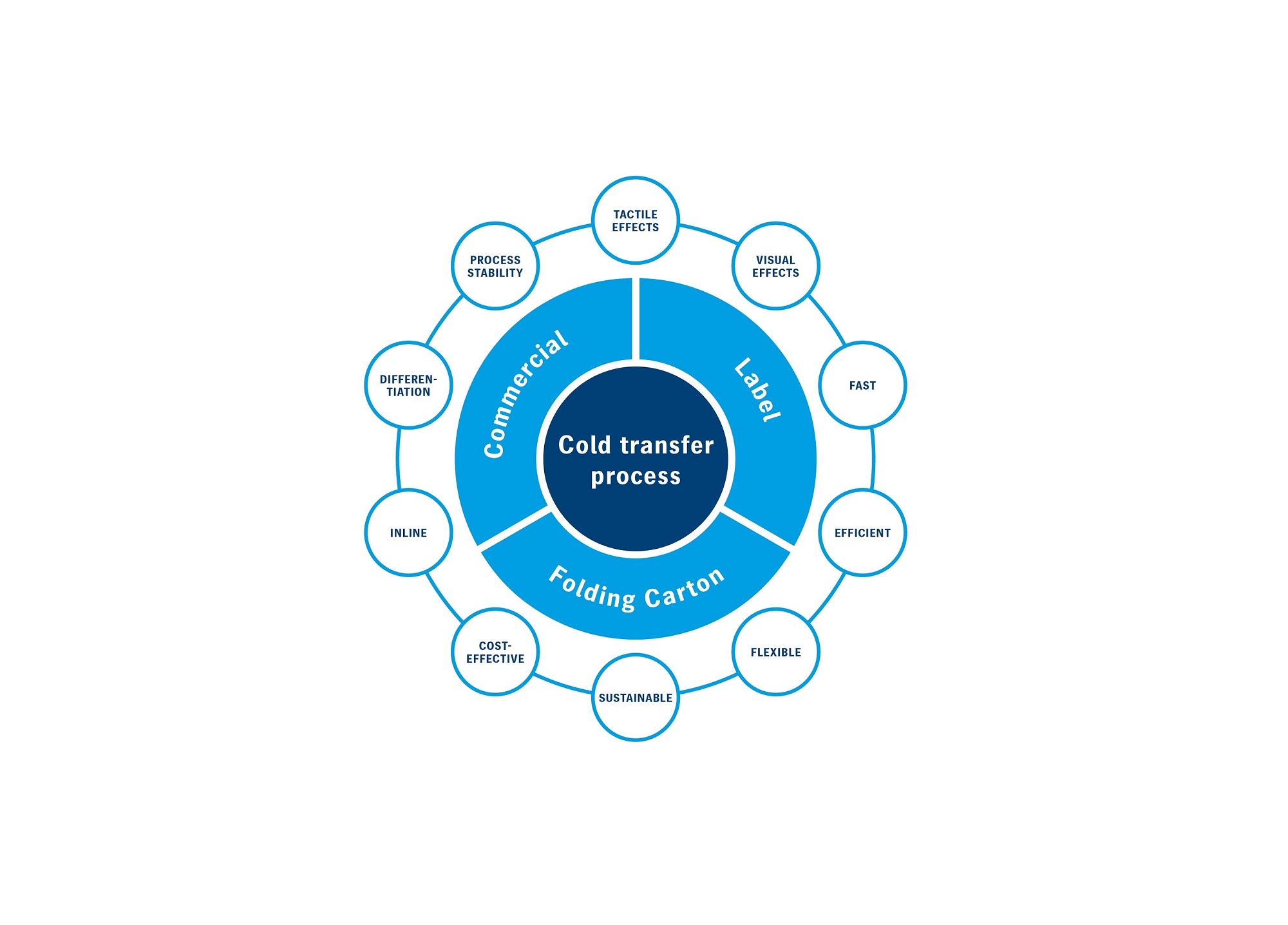

Really standing out at the POS has become a never-ending cycle of innovation and imitation. No sooner has a product with a brand new packaging design landed on store shelves than its first imitators arrive and the whole process starts up again. To put it another way, I need a steady stream of new and striking effects that will trigger a fresh impulse to buy. This applies especially to premium products from the respective brands. On top of that, profit margins start to melt away as run sizes get smaller when using hot foil embossing. When it comes to aluminum-laminated materials, recyclability is poor. All these elements are boosting the trend toward cold transfer, which is now unmistakably taking hold on a global level.

Why was a new technique needed for in-mold labels?

The reason is that, in the past, achieving metallic effects on foil meant having to compromise on quality and productivity. Metallic printing inks don’t achieve the same metallic gloss as cold film. Furthermore, the previous sheetfed offset UV technique could not deliver process stability for cold transfer. That is why we have taken an established technique used in the narrow-web sector and adapted it for our Speedmaster XL 106. New standards are now being set for gloss, adhesion, and process reliability in the sheetfed sector.

What is so special about FoilStar Cure?

First, there is the use of LED UV technology. This means we can achieve better drying performance while at the same time reducing the heat applied to the IML film and energy consumption. Second, we have made changes to the application in key areas. This has enabled us to perfect cold transfer for industrial IML production.

How does it work?

An LED-UV adhesive is applied to the IML film in the first printing unit. The aluminum pigments are applied in the second printing unit. A change to the web guidance for the cold foil means that it stays on the impression cylinder for longer. This is where the foil is dried from above by our DryStar LED Pro dryer, which causes the aluminum pigments and the adhesive to crosslink with a closer bond as it cures. This technique produces metallic pigments that exhibit much better adhesion and a stronger gloss effect and results in high process stability.

What are the products and markets with especially strong demand for FoilStar Cure?

Brand owners and retailers appreciate the additional options for differentiation, particularly when it comes to foods. Two thirds of the in-mold labels manufactured worldwide are destined for this market. During field tests, we used low-migration LED UV consumables – inks, adhesives, and gloss coating – and cold foils that are certified for food use. Although the first press went to Russia, it led the way for a series of other customers from Europe and North America. China is on the rise, too.

Why is cold transfer emerging as a stronger rival to other techniques such as hot-foil embossing and aluminum lamination?

Cold transfer combines a wide diversity of effects with a high processing speed of up to 15,000 sheets per hour. Every desired metallic effect can be achieved inline in a single pass. Cold foil is usually silver in color, but other colors such as gold, bronze, and copper, as well as holographic and rainbow effects are already available prefabricated. Alternatively, the aluminum pigments can be overprinted with process or spot colors directly after being applied, in the same pass. A final coating application for special visual or tactile effects such as matt, gloss, and soft touch finishes can also be applied inline. Waiting times and additional tool costs – for embossing dies, for instance – are eliminated. This makes the cold transfer technique much faster, more flexible, and better value than hot foil embossing. Given that run sizes are shrinking, it has a clear advantage.

What are the benefits when it comes to the all-important issue of sustainability?

Packaging that utilizes cold transfer surface finishing techniques can be recycled, as the aluminum pigments transferred to the substrate can be separated off during the recycling process. What’s more, the indexing lengths on FoilStar are customizable to suit the print subject. Aluminum pigments are only transferred to the specified areas of the packaging. Depending on the subject, that saves up to 80 percent of material, protects the environment, and lowers material costs. This means brand owners have nothing to worry about when it comes to sustainability.

For which presses is FoilStar available?

It is available for the Speedmaster XL 106, CX 104 and XL 75 series. FoilStar can be retrofitted to the Speedmaster XL 106, XL 105, CX 102, CX 104, CD 102, XL 75 and CD 74 series. Foilstar Cure is so far available for the Speedmaster XL 106.