The trend towards shorter runs in the pharmaceutical industry is characterized by different package sizes and highly specialized medicines. Print shops therefore really have to step on the gas when performing job changes if they want their production to be profitable. “Like in Formula 1, the race against time and unit costs is not only decided by speed, but also the time spent in the pit stop,” asserts Jürgen Link, Product Manager at Heidelberg. And this is precisely where the Speedmaster XL 75 Anicolor 2 , with its short makeready times, shines.

A color change with three or four spot colors can be easily performed in less than five minutes with the Speedmaster XL 75 Anicolor 2. This is because the Anicolor has something that printers have always wanted: the complete ink chamber can be easily removed from the machine in a few simple steps and replaced with another one containing the next spot color. And all within just seconds. “The ink chamber for the next job can be prepared with a new spot color while production is still underway. The used ink chamber is put aside if the same spot color is needed in one of the subsequent jobs,” explains Jürgen Link.

The other benefits of the Anicolor technology come into play after the ink is replaced. The machine does not use ink zones. The fast and constant inking means that a new job is ready to print after just 30 start-up sheets, give or take. With standardized workflows, the color sample and produced print job are an exact match. This increases productivity by up to 50 % and reduces start-up sheet consumption by up to 90 % compared with conventional offset machines.

The challenge in the pharmaceutical folding carton sector is to keep the repeats with their small areas and lettering in spot colors constant across the sheet and the entire run, and to achieve the fastest possible inking-up with only a few start-up sheets. Yet another challenge that can be easily mastered with the Anicolor. This is ensured by the technologically sophisticated inking unit: a format-size screen roller and an ink form roller apply the desired ink volume to the printing plate. This selective ink transfer means that it makes no difference whether only a small area or piece of lettering or an area spanning the entire sheet needs to be printed. With each revolution, the printing plate gets the exact amount of ink needed to print the desired area. The design therefore rules out over-inking or under-inking. Precise metering of the ink volume is achieved by heating or cooling each individual screen roller. The result is uniform inking across the entire run, even with the lowest possible ink consumption. This enables the quality standards of the pharmaceutical industry to be reliably met, and the finest security features such as micro lettering to be perfectly printed.

Standardized color management in combination with Saphira consumables also contributes to production reliability. “We have optimally tailored the Saphira process and spot colors to the Anicolor technology. The spot colors correspond to the PANTONE® Matching System,” emphasizes Jürgen Link. The benefit of this for print shops is that they can process the color systems approved the customer. They can also achieve the same color reproduction in print jobs produced on the Speedmaster XL 75 Anicolor 2 or on conventional offset machines.

It should come as no surprise that the Speedmaster XL 75 Anicolor 2 can also meet special requirements. Anti-counterfeiting protection plays an important role in the pharmaceutical industry. Every second drug sold online is now considered to be counterfeit*. As security features, the Anicolor processes fluorescent inks that illuminate under black light and coin reactive inks that only become visible when they come into contact with a coin or metal.

In the fast-growing OTC segment (over-the-counter market), the strengths of the Speedmaster XL 75 Anicolor 2 go beyond anti-counterfeiting protection: “When it comes to attention-grabbing effects such as metallic inks like gold and silver or opaque white on expensive substrates like metalized cardboard, every sheet of waste paper saved reduces the unit costs,” emphasizes Jürgen Link. “But the Speedmaster XL 75 Anicolor can also produce coating effects easily and cost effectively with one coating unit. And in UV on request.”

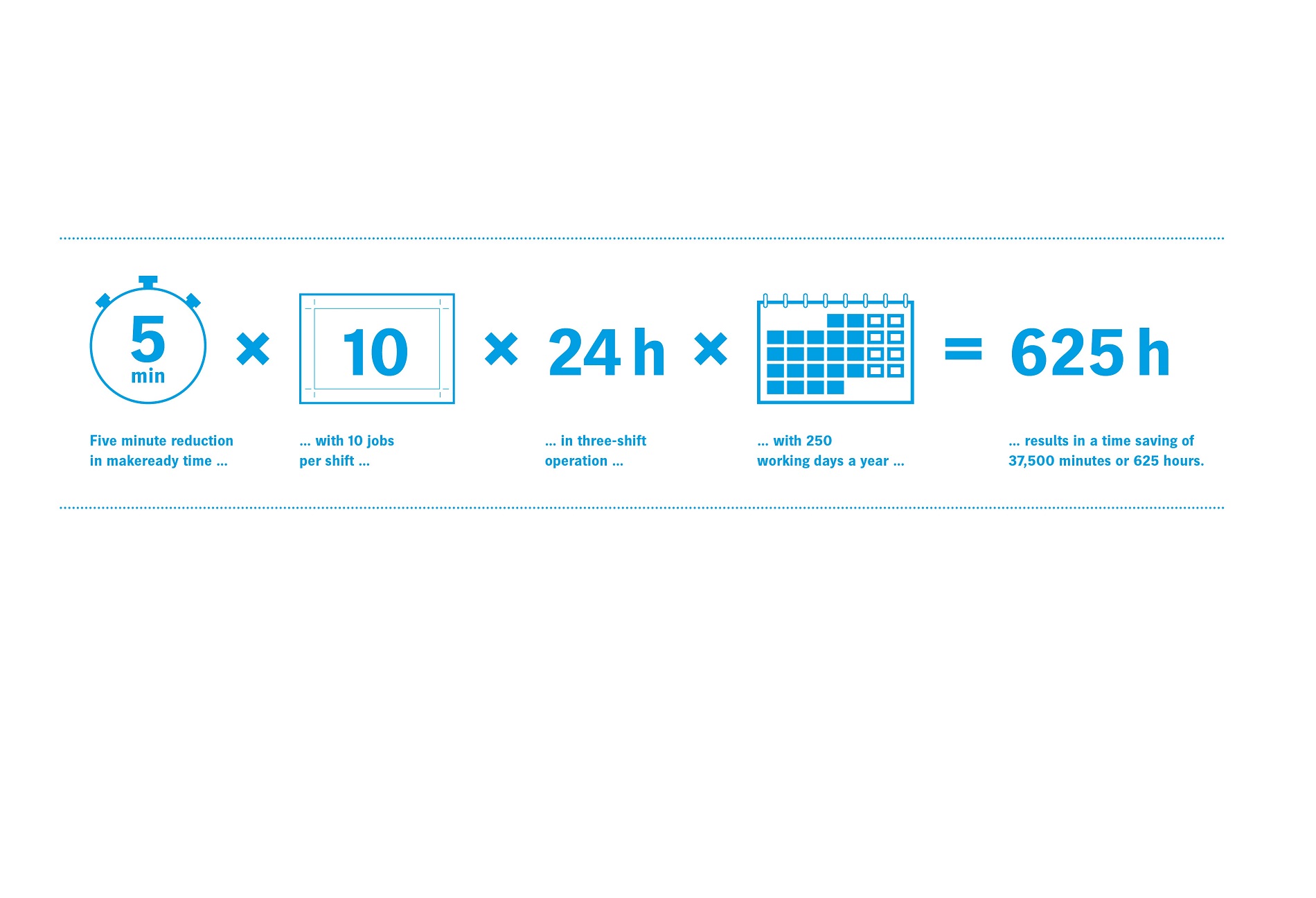

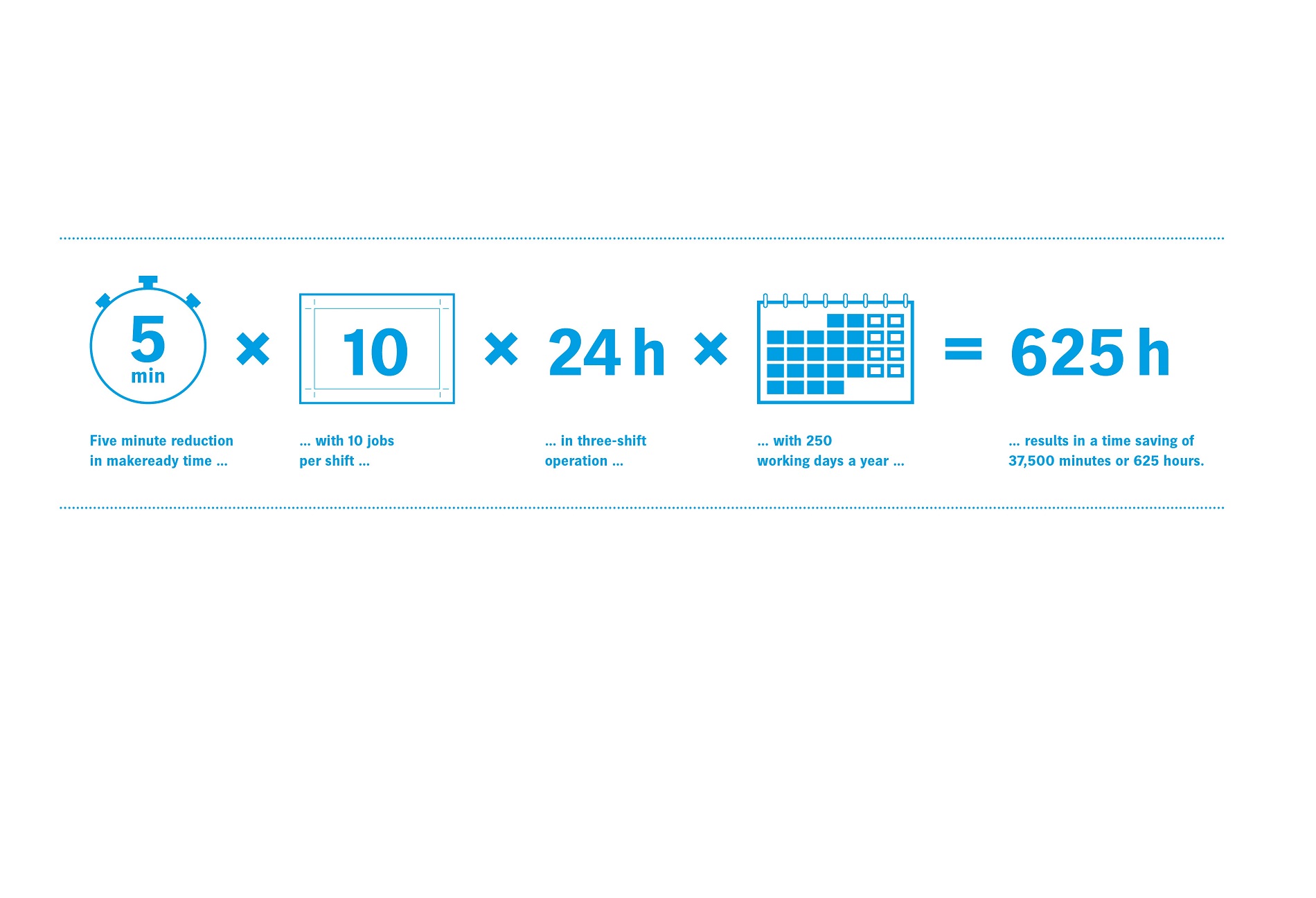

“The economic benefits and print quality are such that customers from the pharmaceutical packaging sector have already invested in the second Speedmaster XL 75 Anicolor 2,” reports the product manager. This is because the shorter the runs and the more frequent the job changes, the greater the benefits of the Speedmaster XL 75 Anicolor 2. For example, the reduction in makeready times with ten jobs per shift in three-shift operation results in additional capacity of an impressive 625 hours per year.

Added to this are the cost advantages of saving material: the reduction in start-up sheets enables businesses to save around €150,000 a year. They also gain flexibility since, depending on their order situation, they can also produce high runs of several tens of thousands of sheets economically using offset printing. “The Speedmaster XL 75 Anicolor 2 has completely won over, if not bowled over, our customers,” says Jürgen Link. “The machine gives them a decisive increase in productivity, cost efficiency, and delivery capability in a highly competitive market.”