Located in Qingpu on the western edge of Shanghai, Heidelberg Graphics Equipment Shanghai (HGES) has celebrated two decades of steady growth since its establishment in 2005.

What began with just 60 employees has grown into a team of nearly 600 professionals, making the site a vital part of the HEIDELBERG global production network. The facility upholds the same high quality standards and engineering expertise as the company’s German headquarters.

Since its establishment, the Shanghai/Qingpu site has been guided by a series of dedicated managers including Stefan Hasenzahl, Achim Mergenthaler, and Michael Nilges, each playing a part in shaping its transformation and success.

From day one, the mission was clear: to create a strong local presence and serve a rapidly expanding market. Qingpu was chosen for its proximity to customers, its pool of skilled talent, and its reliable supplier base, - all critical ingredients for sustainable growth.

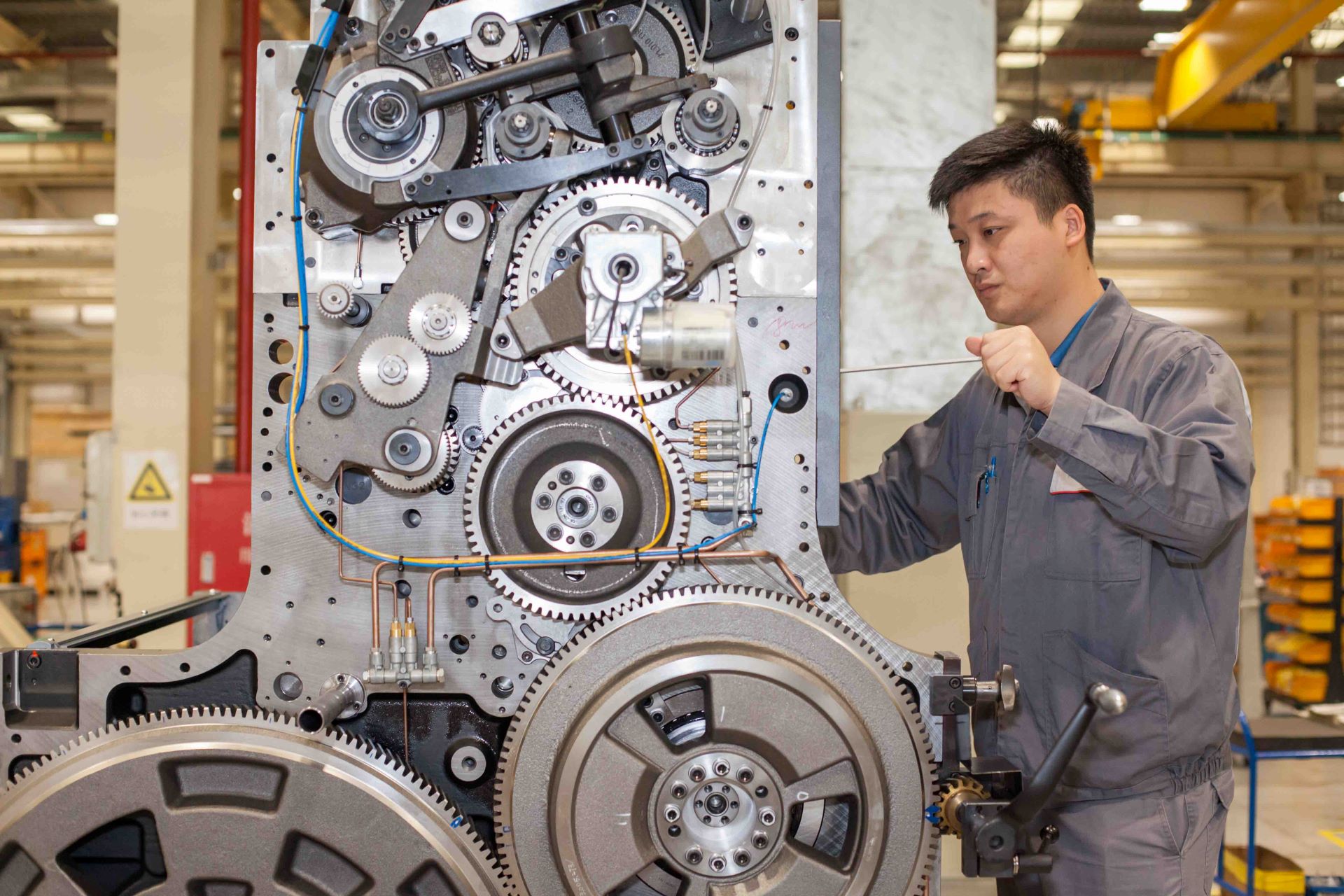

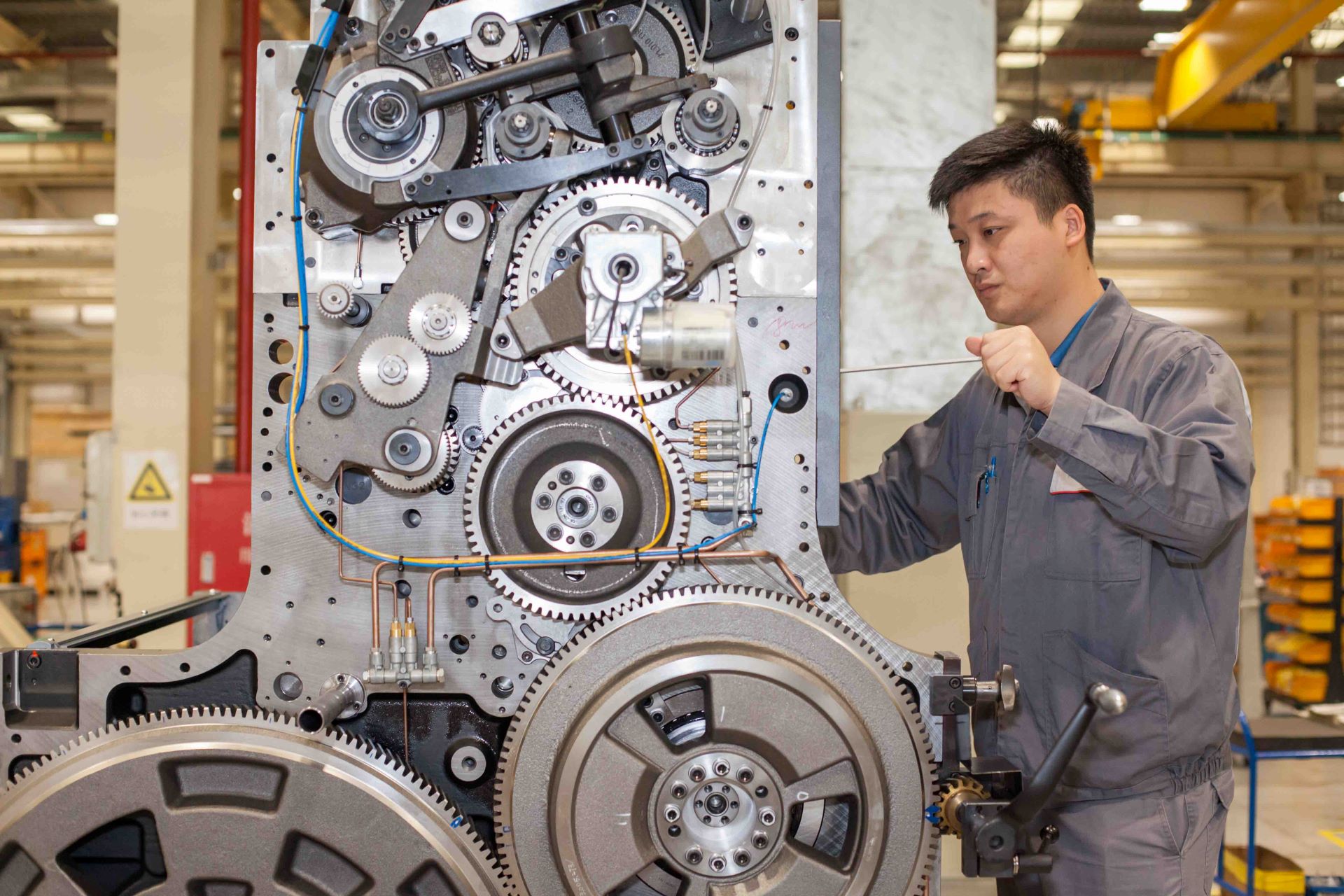

Production began with folding machines. By 2006, the Speedmaster SM 52 joined the line, followed by larger formats such as the Speedmaster SM 74 and Speedmaster CD 102. Expansion continued with a second production hall in 2011. Today, the facility covers 100,000 square meters, including 70,000 square meters of production space, making Shanghai the largest manufacturing site of HEIDELBERG outside Germany.

As capabilities grew, Qingpu evolved from a local operation into a global production hub, delivering sophisticated models like the Speedmaster CD 102 to customers around the world, particularly in the packaging sector.

Over the years, the Qingpu/Shanghai site has celebrated many milestones:

Achim Mergenthaler, now Director of Operations at HEIDELBERG, recalls: “What impressed me most was how a small production line became a real manufacturing facility. Every milestone — new buildings, new machines, new awards — was based on teamwork. It wasn't just technical growth, but also the spirit of unity, learning, and commitment that shaped Qingpu.”

Today, the site produces mid- and large-format presses, with around 80% of its supply chain sourced locally..

China is for HEIDELBERG the largest single market for printing presses, driven by strong demand from the packaging and consumer goods sectors, as well as the rise of advanced print service providers.

The presses manufactured in Shanghai meet the same reliability, usability, and efficiency benchmarks as those made in Germany. They are then shipped across Asia and Europe.

“The Speedmaster SX 102 and Speedmaster CX 104 are now fully assembled here in Qingpu" explains factory leader Michael Nilges. "Every order for these models is fulfilled from this site.”

To date, presses from Qingpu have been delivered to more than 70 countries, with over 16,000 printing units and 3,000 complete presses shipped since 2005. The site has become a vital link in the global production chain of HEIDELBERG.

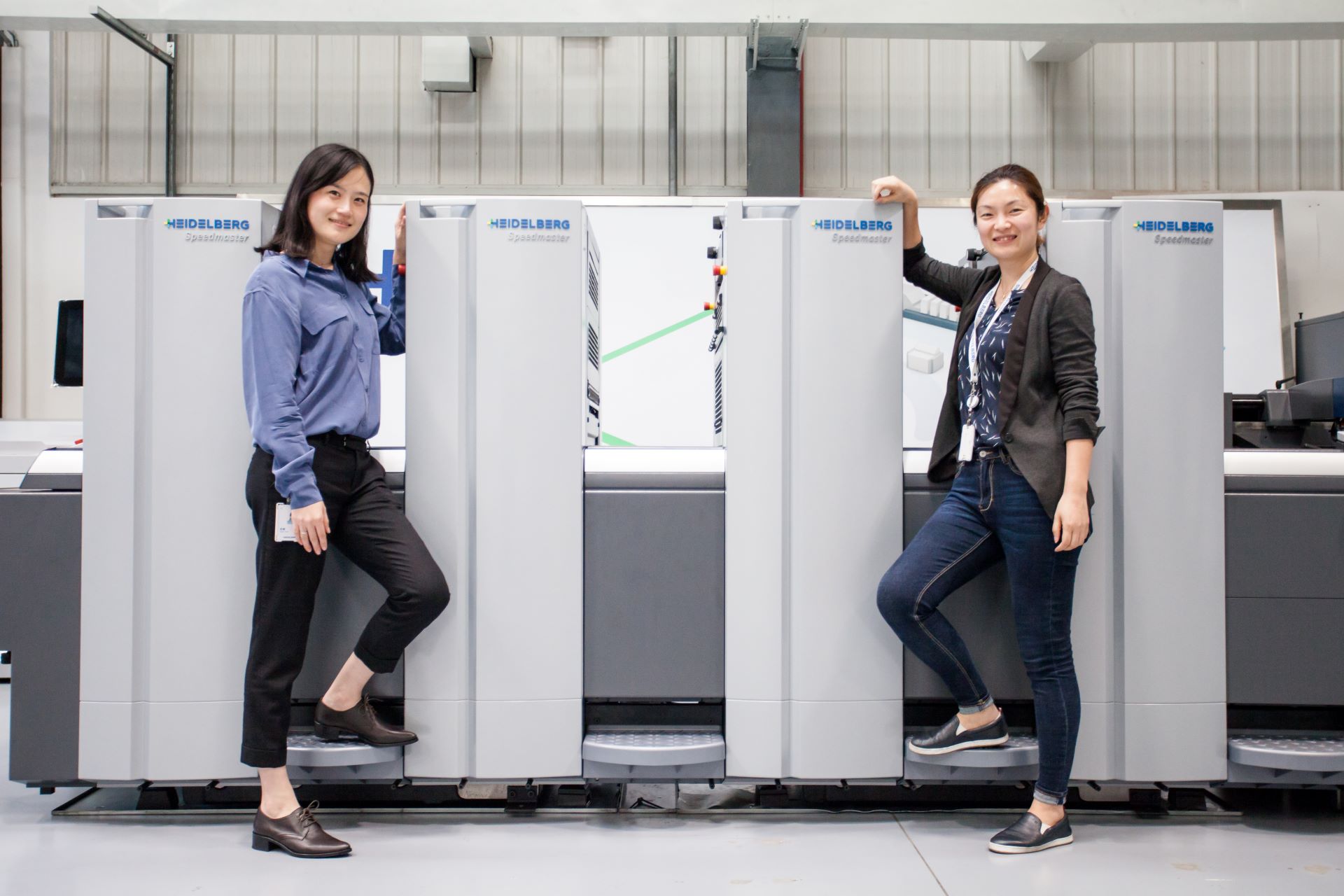

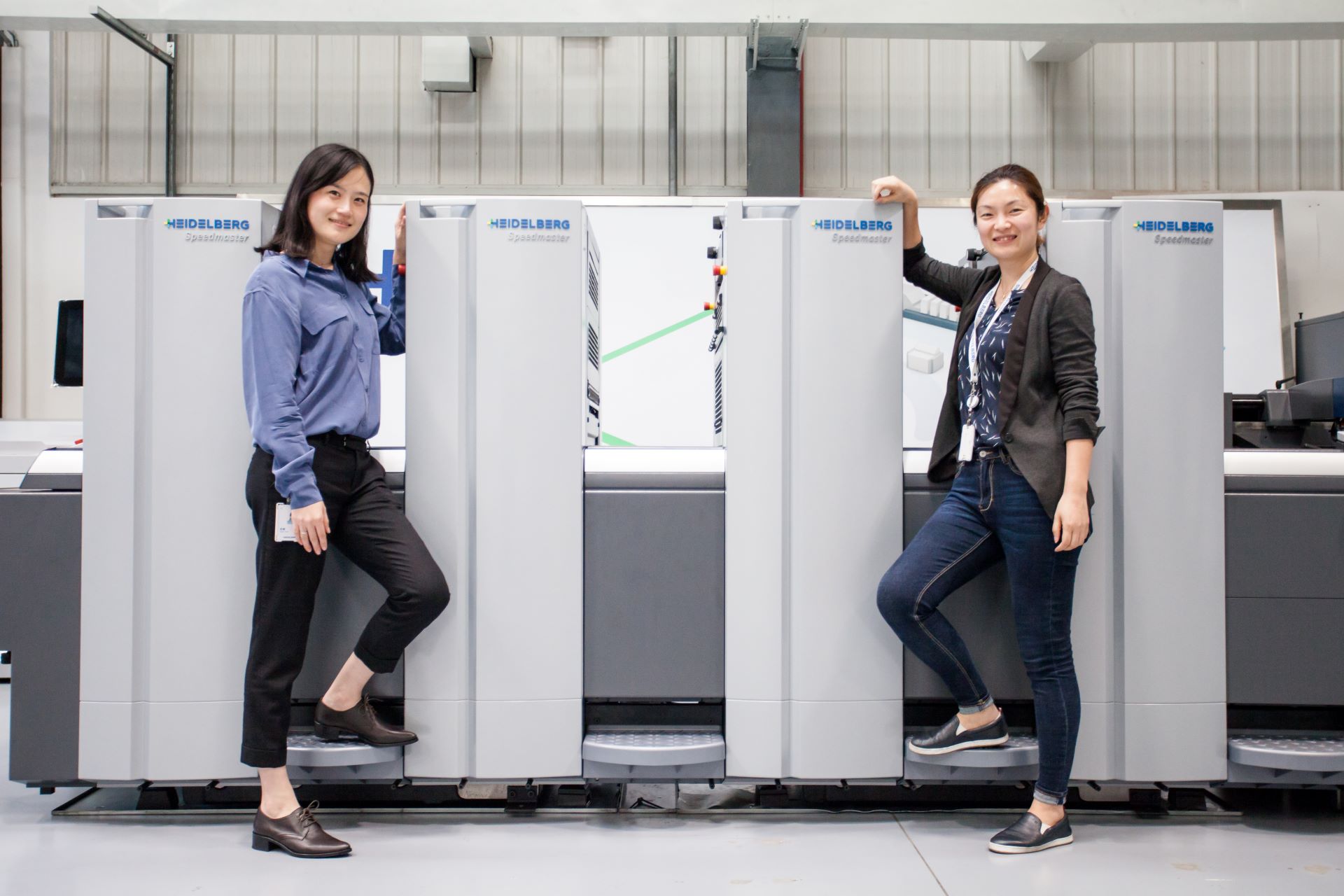

Qingpu’s success story is, above all, a story about its people. Many of the nearly 600 employees have been part of the company since the early days. The workplace culture is built on respect, continuous learning, and teamwork. “Qingpu feels like a family,” says Nilges. “From managers to line workers, everyone pulls together. That’s how we meet ambitious targets and deliver on time.”

From the start, collaboration between Chinese and German teams has been close and genuine. Stefan Hasenzahl recalls: “We treated each other with honesty and respect, and built friendships that have lasted to this day. The spirit here is hardworking, eager, and proud. If I had to choose one word, it would be ‘Gung Ho’ – all in, full of energy.”

Through joint training, aligned processes, and continuous exchange with Wiesloch headquarters, Qingpu has become an inseparable part of the HEIDELBERG family.

Today, Qingpu is a key part of the global HEIDELBERG production network. The site continues to drive innovation and respond efficiently to market needs, with local teams taking on broader responsibilities in product development and manufacturing.

There’s much to learn between sites. Mr. Hasenzahl notes: “German colleagues can learn from China’s flexibility.” Qingpu’s quick response, practical solutions, and efficient execution have inspired new thinking in Germany. In return, Qingpu gains from Wiesloch’s structured ways, long-term vision, and deep engineering expertise, keys to lasting growth and excellence.

Mr. Mergenthaler adds: “In Qingpu, decisions can be made fast and direct. That’s a strength we don’t always have in Germany. Sometimes, we should be bolder.” He emphasizes the strong partnership: “Shared standards and close ties with Wiesloch are the heart of our success.”

The collaboration between Qingpu and our global teams has turned the site into more than just a manufacturing location: it’s a key contributor to the ongoing development of HEIDELBERG. With a strong foundation in shared standards, continuous learning, and practical innovation, Qingpu is well positioned to support the company's future growth and evolving market needs.