Whether the “Heidelberg Platen” press, the GTO, or the Speedmaster – the printing presses from HEIDELBERG have written Germany’s industrial history. Having consistently expanded its expertise in precision component manufacturing, metalworking, and the integration of complex electronic systems, the company now aims to harness this potential even more extensively – including in sectors other than the printing industry.

“Our portfolio covers the development and production of complex systems and equipment, as well as mechanical component manufacturing and the production of power electronics,” says CEO Jürgen Otto. He explains that, in contrast to conventional contract manufacturers, HEIDELBERG industrial customers have a key advantage. “Not only do they get the hands-on, practical support, but they also get an entire package that includes the combined expertise of an industrial company – from development, complete with testing and validation, all the way through to production. We offer top-performance products with integrated, maintenance-friendly software and global service,” he continues.

The current geopolitical developments have reshuffled the deck. Global tensions, trade conflicts, and the Covid-19 pandemic are forcing companies to rethink their supply chains. “Given the global economic and geopolitical situation, the concept of ‘local for local’ is gaining importance once again,” says Klaus Braun, Head of HEIDELBERG Industry. “Short supply chains and supply security are back in the spotlight, making Germany increasingly attractive as a production location.”

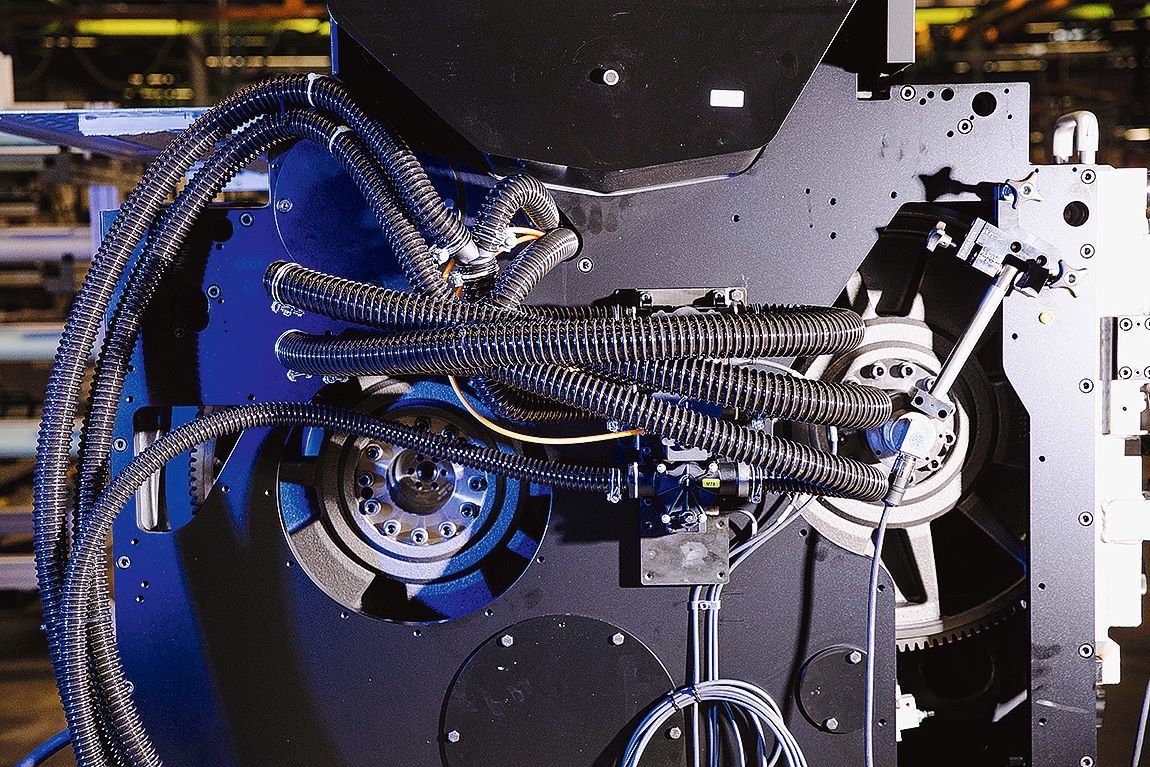

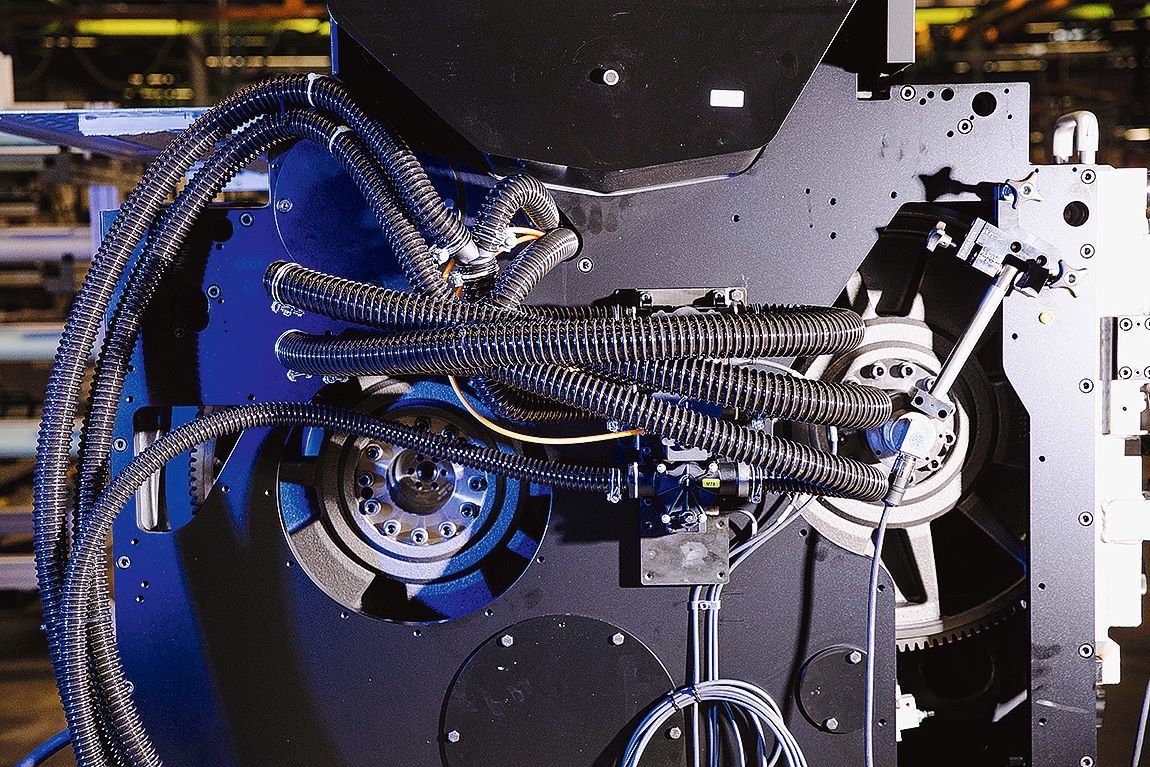

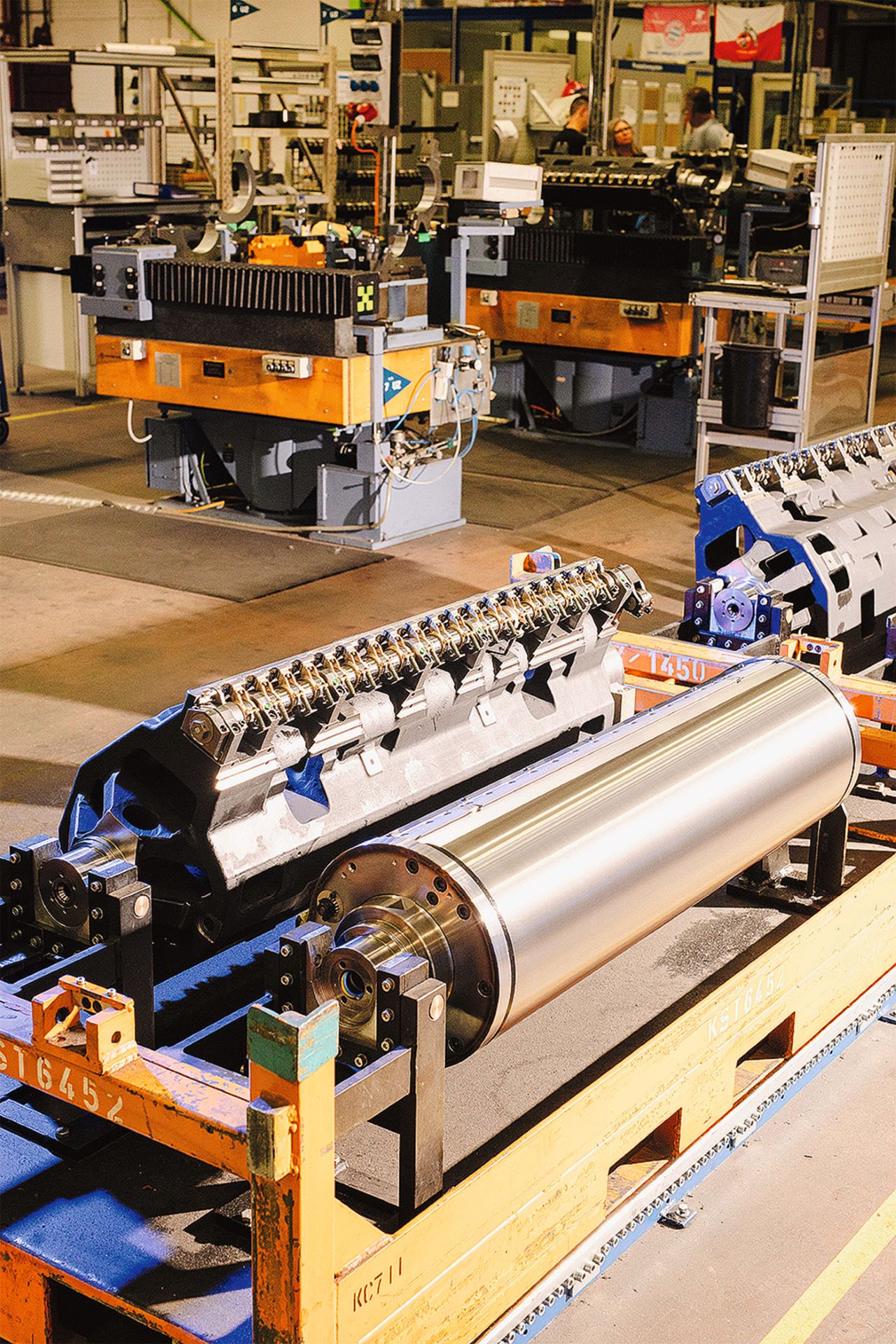

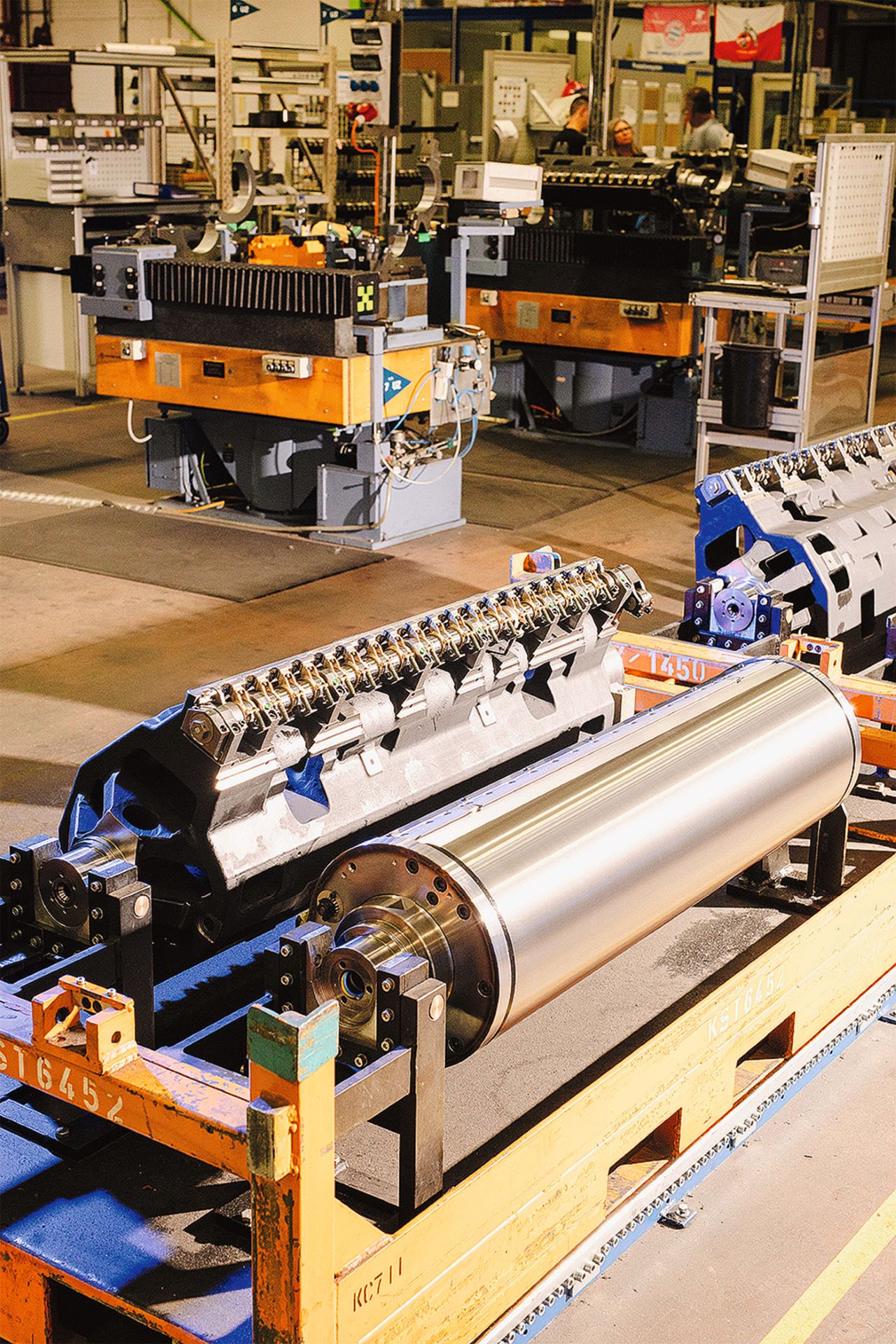

What sets HEIDELBERG apart from its competitors is its exceptional depth of manufacturing. While some competitors offer only individual production steps, HEIDELBERG covers complete value chains. From metal processing to the final assembly of highly complex systems — everything takes place under one roof. The sites in Wiesloch-Walldorf, Brandenburg an der Havel , and the company’s own foundry in Amstetten play a central role. They benefit from short supply chains and enable tailor-made production solutions.

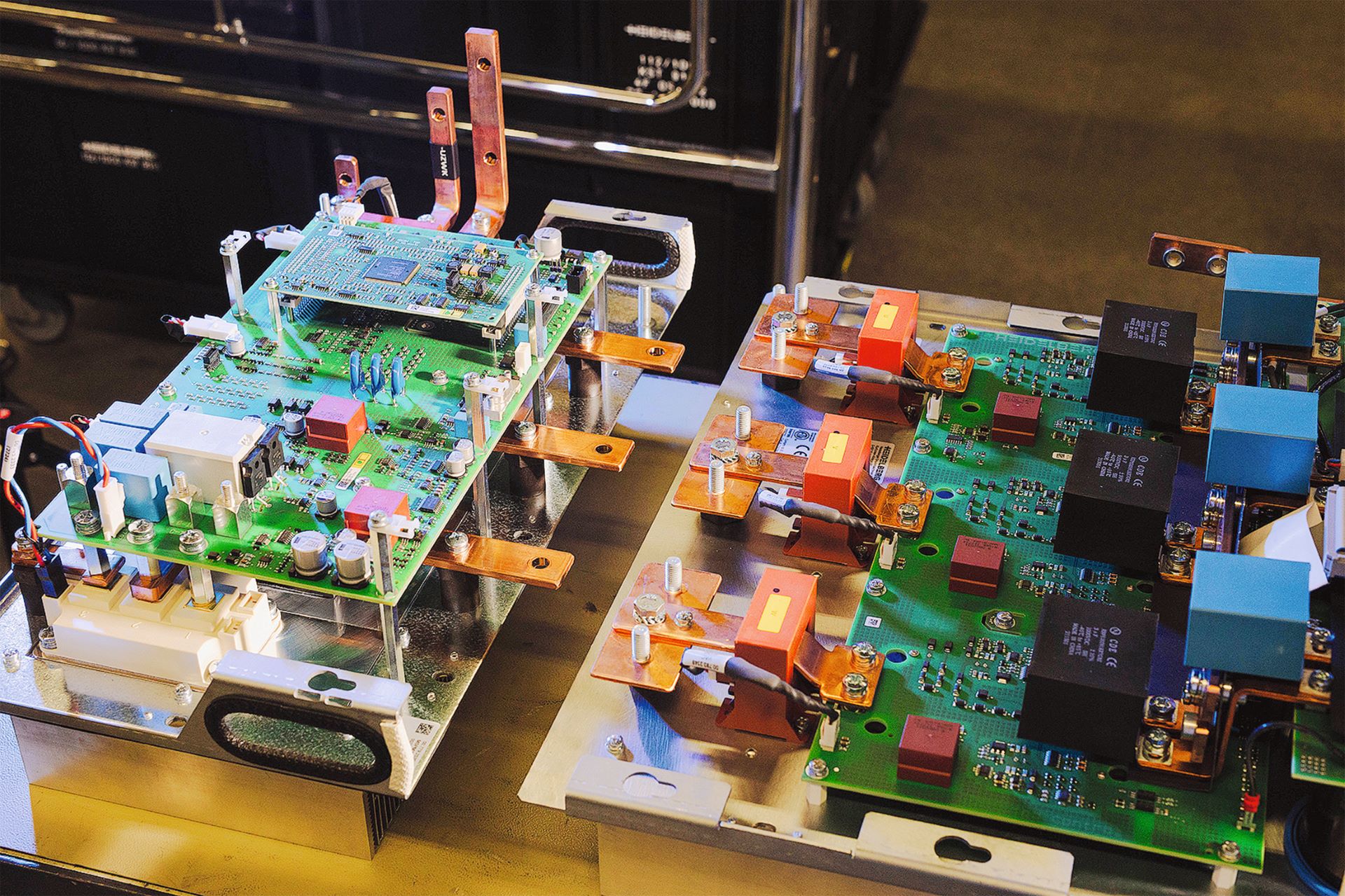

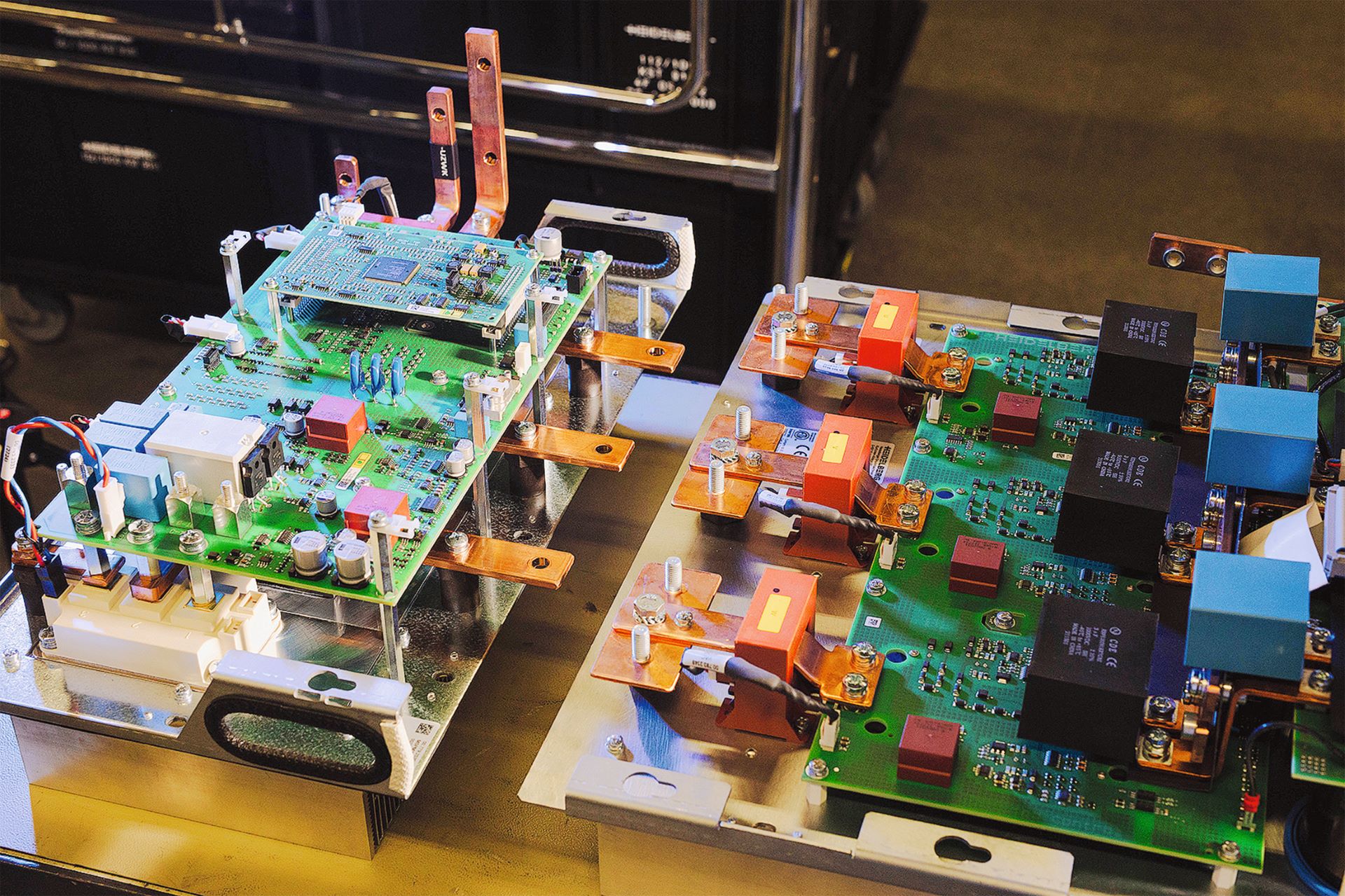

Additionally, HEIDELBERG possesses extensive expertise in power electronics. The company’s ability to internally develop, manufacture, and globally integrate complex electronic controls into power grids makes it a sought-after partner in industries such as automotive and automation technology. HEIDELBERG’s range of services includes components as well as the development of complete products.

The industrial manufacturing sector has become a central pillar of the company’s strategy. “As a technology corporation, we look for opportunities to apply HEIDELBERG’s capabilities and resources beyond the printing industry,” says Sascha Donat, Head of the Technology Segment. “The company possesses extensive capacity and know-how in highly precise, highly automated heavy machinery, applicable to the automotive industry and energy sector alike.”

This approach enables the company to tap into new markets. A standout example of successful diversification is the subsidiary Amperfied, which offers innovative charging solutions for electric mobility. The synergies are clear: electronic controls are developed, tested, and assembled on-site in state-of-the-art production facilities. Amperfied exemplifies how HEIDELBERG leverages its manufacturing depth and technological expertise to successfully enter new business areas. “Working with HEIDELBERG allows us to access first-class production infrastructure and deliver products of the highest quality,” says Robin Karpp, CEO of Amperfied.

A milestone in this development has been expanding the product portfolio beyond hardware. Florian Franken, Head of Product Management and Business Development at Amperfied, explains: “Less visible than our wallboxes, but no less important, are Amperfied’s cloud-based backend for managing charging points and Amperfied Rental as a flexible financing solution. Together, these offerings form the foundation for our growth plans and our transformation into a comprehensive solutions provider.”

Robin Karpp, Managing Director of Amperfied

The next step for Amperfied is entering the fleet solutions market and building its institutional business. A key enabler is the strategic partnership with DB Bahnbau Group. “Our collaboration with DB Bahnbau Group allows us to leverage their extensive network and infrastructure expertise. The effort required for civil engineering in setting up charging infrastructure is often underestimated,” says Karpp. “This partnership positions us to deliver large-scale charging solutions across Germany more effectively.”

Additionally, the company plans to launch a high-power DC fast-charging system, which Karpp describes as “a game-changer” for Amperfied. With a charging capacity of 400 kilowatts, it is ideally suited for ultra-fast charging along highways. “Our DC charging solutions, as well as our infrastructure for commercial and public applications, will be critical for continued growth. We also prioritize high uptime for all charging points. Overall, these offerings generate stable and recurring revenue streams,” Karpp explains.

With its renewed focus on industrial manufacturing and utilization of in-house production capabilities, HEIDELBERG is well-positioned to meet future challenges. Trends such as re-regionalization and nearshoring – leveraging lower production costs within Europe – open up new opportunities.

“HEIDELBERG is already a trusted partner to customers through 250 locations in 170 countries, offering a comprehensive global sales and service network across industries,” says CEO Jürgen Otto. The goal now is to extend this network beyond the printing sector and demonstrate the company’s manufacturing excellence to new industrial clients.