04/18/2024

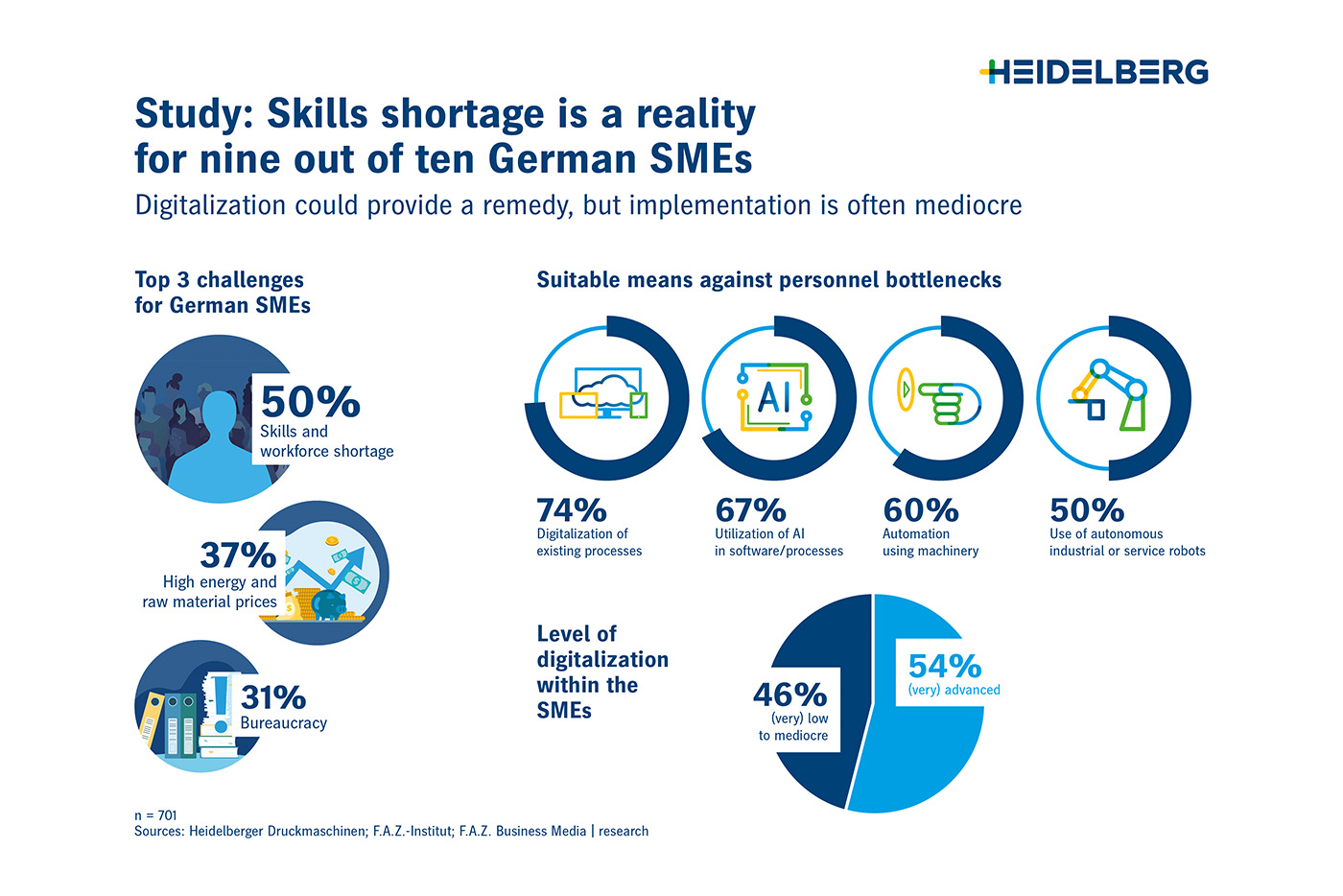

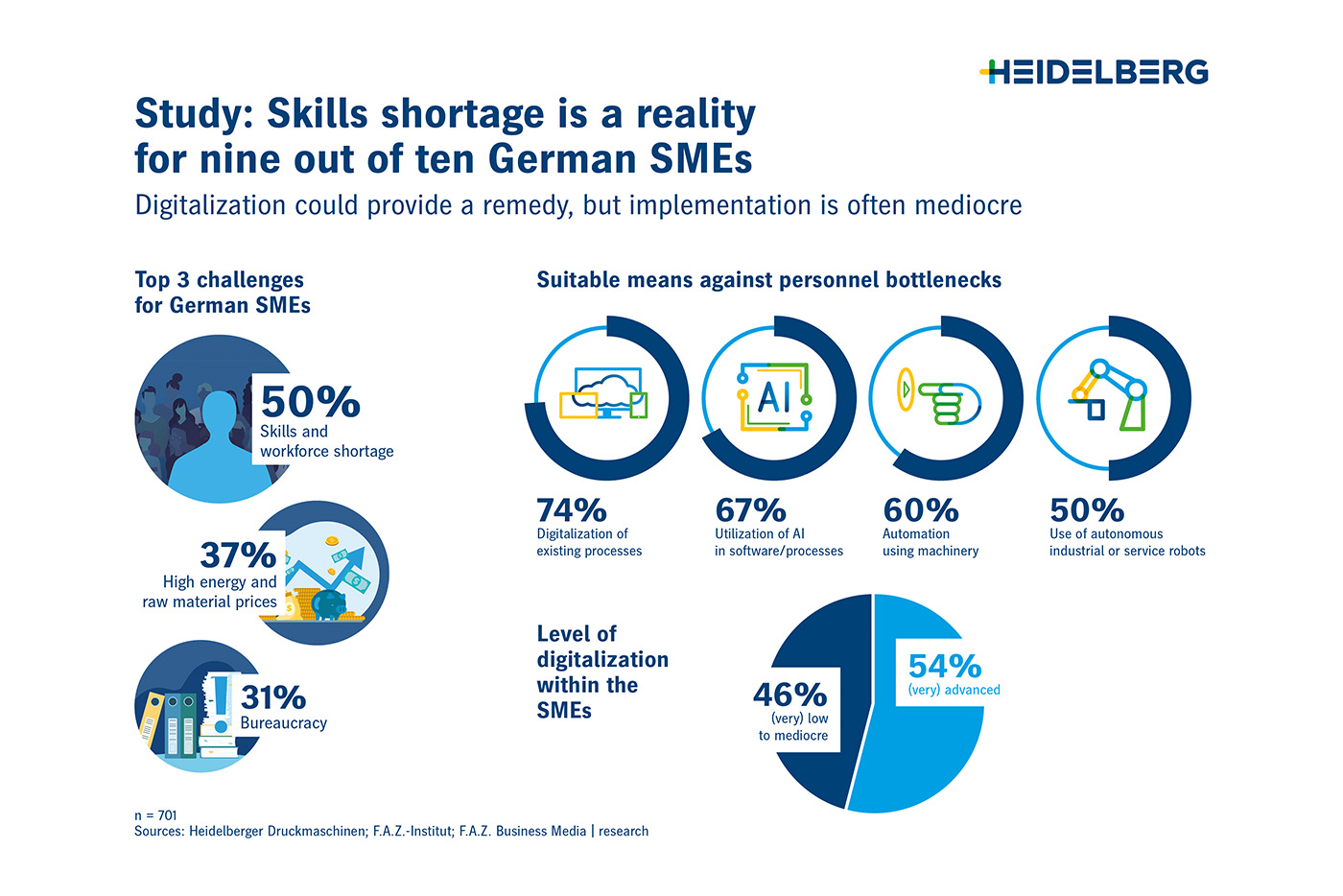

German SMEs are suffering a massive skills and workforce shortage – a fact highlighted by a representative survey among SME decision-makers that the F.A.Z. Institute conducted for Heidelberger Druckmaschinen AG (HEIDELBERG). According to this survey, nine out of ten German SMEs do not have enough staff. Just under half (49 percent) said they were badly or very badly affected by the skills and workforce shortage. “Our customers in the printing industry have been facing a skills and workforce shortage for years. HEIDELBERG therefore wanted to know whether this is a general trend among German SMEs. Our solutions for combating staff shortages at print shops are automation and digitalization, which make jobs more technical and also mean these jobs appeal to a larger number of potential recruits. This strategy can serve as an example for SMEs from other sectors,” says HEIDELBERG CEO Dr. Ludwin Monz.

Using the latest machines, print shops can work fully automatically in both packaging production and commercial printing. The entire process is digitalized. Robotics systems complement the presses, meaning that print shops can manage with fewer prepress and postpress staff as well. For example, the new coexisting StackStar C robot works directly alongside people and relieves them. “All German SMEs need a strategy that enables them to compensate for staff shortages using state-of-the-art technologies, and yet the survey shows that many small and medium-sized enterprises still have some catching up to do in terms of digitalization,” continues Monz.

According to the study, almost half of SMEs rate their own companies as no better than moderate when it comes to digitalization. At the same time, however, making greater use of technology is a good way for many SMEs to compensate for staff shortages. Three-quarters of respondents (74 percent) are looking to the digitalization of their work processes as a remedy. Two-thirds (67 percent) regard the use of artificial intelligence (AI) in software and their own processes as an effective means of minimizing staff shortages at their company. Industrial SMEs in particular see opportunities in the further automation of their production. Some 67 percent of respondents from the manufacturing sector feel machine- based automation is a good way of tackling the skills and workforce shortage, while 58 percent of industrial SMEs think using industrial and service robots is a good idea.

“The German economy still has a lot to do when it comes to digitalization, and that goes beyond individual companies,” says Monz. Seven out of ten respondents rate the digitalization of Germany’s economy as no better than moderate. Only just under a third consider it to be advanced or very advanced.

Germany requires digital and automated processes to remain a successful major industrial location in the future. Some 91 percent of the SMEs responding to the survey agreed that Germany’s economy is not competitive without digitalization and automation.

The issues ranked highest by SMEs when asked about the most pressing problems at the present time were the skills and workforce shortage (50 percent), high energy and raw material prices (37 percent), and bureaucracy (31 percent).

HEIDELBERG asked the F.A.Z. Institute to conduct a representative survey of 701 companies with fewer than 500 employees in order to find out whether the skills and workforce shortage is as widespread in German SMEs as it is at print shops. HEIDELBERG offers print shops cutting-edge, networked, and highly automated machinery, robotics systems, control software, and cloud solutions. Assistance systems with in-built artificial intelligence can be used to automate processes, even to the extent of implementing autonomous printing. B2B platforms for consumables and service parts, software for controlling the entire workflow in the printing process, and Internet-based remote diagnoses for machine maintenance are also included in the portfolio.

Download Infographic with key results of the survey: Skills shortage at 9 out of 10 SMEs in Germany. Digitalization could help, but implementation is often only mediocre.

Download survey results from the F.A.Z. Institute

You will find a video about workforce issues in the printing industry on our drupa website for the 2024 industry trade show.

Figure 1: The new Speedmaster XL 106 from the Peak Performance generation is being showcased at drupa 2024. Geared toward the future, its performance is further enhanced by cloud functions. It also benefits from even more AI software that can think for itself. Thanks to fully automatic printing plate logistics, the press is highly productive and needs fewer operators.

Figure 2: The new coexisting robot "StackStar C" does not require a safety fence, but has an innovative safety concept that works with mobile markers, among other things. The "StackStar C" relieves people in the further processing of printed matter. It thus expands HEIDELBERG's robotics range, which has included the industrial robot "StackStar P" (formerly "Stahlfolder P-Stacker") since 2020.

Oliver Claas

Press Officer

Tel.: +49 (0)6222 82 67179

Email: oliver.claas@heidelberg.com

04/18/2024

German SMEs are suffering a massive skills and workforce shortage – a fact highlighted by a representative survey among SME decision-makers that the F.A.Z. Institute conducted for Heidelberger Druckmaschinen AG (HEIDELBERG). According to this survey, nine out of ten German SMEs do not have enough staff. Just under half (49 percent) said they were badly or very badly affected by the skills and workforce shortage. “Our customers in the printing industry have been facing a skills and workforce shortage for years. HEIDELBERG therefore wanted to know whether this is a general trend among German SMEs. Our solutions for combating staff shortages at print shops are automation and digitalization, which make jobs more technical and also mean these jobs appeal to a larger number of potential recruits. This strategy can serve as an example for SMEs from other sectors,” says HEIDELBERG CEO Dr. Ludwin Monz.

Using the latest machines, print shops can work fully automatically in both packaging production and commercial printing. The entire process is digitalized. Robotics systems complement the presses, meaning that print shops can manage with fewer prepress and postpress staff as well. For example, the new coexisting StackStar C robot works directly alongside people and relieves them. “All German SMEs need a strategy that enables them to compensate for staff shortages using state-of-the-art technologies, and yet the survey shows that many small and medium-sized enterprises still have some catching up to do in terms of digitalization,” continues Monz.

According to the study, almost half of SMEs rate their own companies as no better than moderate when it comes to digitalization. At the same time, however, making greater use of technology is a good way for many SMEs to compensate for staff shortages. Three-quarters of respondents (74 percent) are looking to the digitalization of their work processes as a remedy. Two-thirds (67 percent) regard the use of artificial intelligence (AI) in software and their own processes as an effective means of minimizing staff shortages at their company. Industrial SMEs in particular see opportunities in the further automation of their production. Some 67 percent of respondents from the manufacturing sector feel machine- based automation is a good way of tackling the skills and workforce shortage, while 58 percent of industrial SMEs think using industrial and service robots is a good idea.

“The German economy still has a lot to do when it comes to digitalization, and that goes beyond individual companies,” says Monz. Seven out of ten respondents rate the digitalization of Germany’s economy as no better than moderate. Only just under a third consider it to be advanced or very advanced.

Germany requires digital and automated processes to remain a successful major industrial location in the future. Some 91 percent of the SMEs responding to the survey agreed that Germany’s economy is not competitive without digitalization and automation.

The issues ranked highest by SMEs when asked about the most pressing problems at the present time were the skills and workforce shortage (50 percent), high energy and raw material prices (37 percent), and bureaucracy (31 percent).

HEIDELBERG asked the F.A.Z. Institute to conduct a representative survey of 701 companies with fewer than 500 employees in order to find out whether the skills and workforce shortage is as widespread in German SMEs as it is at print shops. HEIDELBERG offers print shops cutting-edge, networked, and highly automated machinery, robotics systems, control software, and cloud solutions. Assistance systems with in-built artificial intelligence can be used to automate processes, even to the extent of implementing autonomous printing. B2B platforms for consumables and service parts, software for controlling the entire workflow in the printing process, and Internet-based remote diagnoses for machine maintenance are also included in the portfolio.

Download Infographic with key results of the survey: Skills shortage at 9 out of 10 SMEs in Germany. Digitalization could help, but implementation is often only mediocre.

Download survey results from the F.A.Z. Institute

You will find a video about workforce issues in the printing industry on our drupa website for the 2024 industry trade show.

Figure 1: The new Speedmaster XL 106 from the Peak Performance generation is being showcased at drupa 2024. Geared toward the future, its performance is further enhanced by cloud functions. It also benefits from even more AI software that can think for itself. Thanks to fully automatic printing plate logistics, the press is highly productive and needs fewer operators.

Figure 2: The new coexisting robot "StackStar C" does not require a safety fence, but has an innovative safety concept that works with mobile markers, among other things. The "StackStar C" relieves people in the further processing of printed matter. It thus expands HEIDELBERG's robotics range, which has included the industrial robot "StackStar P" (formerly "Stahlfolder P-Stacker") since 2020.

Press Officer

Tel.: +49 (0)6222 82 67179