Did you know? HEIDELBERG offsets the greenhouse gas emissions generated in the manufacture of all folding machines by purchasing climate protection certificates. This means you can be sure that you are helping to protect the environment when you buy a Stahlfolder machine.

This is because the kinds of critical speeds at which faults are likely to occur in the folding process are not actually necessary to achieve output of over 18,000 sheets per hour when producing 16-page signatures in A4 format.

This innovative concept makes the Stahlfolder TX 96 folding system an absolute peak performance machine. The combination of oblong format processing and shingled folding pairs two methods of increasing performance in one machine. The result is optimum efficiency – a completely new level of performance in industrial signature folding.

This peak performance is easily accessible to you. This is because the machine configuration comprising two folding stations with six buckle plates and pre-assembled slitter shafts is optimally coordinated and designed for the highest productivity. The folding programs together with all fine adjustments and the Air Management settings can be saved and quickly called back up for repeat jobs.

The secret to the success of the Stahlfolder TX 96 is therefore increasing the performance while keeping the machine speed the same through shingled folding and oblong format processing. This is how your folding machine keeps up with the performance of your press. Guaranteed.

Pallet feeder PFX – shingled feeding and two-step acceleration of sheets

With the PFX pallet feeder it is possible to feed sheets into the folder in an overlapping shingle-stream, and no longer separately with sheet gap as before. Due to the overlapping of the sheets their infeed length is almost halved depending on the fold type. Much more sheets can be fed at the very same machine speed. Up to this day, this technology is unique and is only available at Heidelberg.

The PFX-feeder is optimized for large circulations to achieve a more stable production even with sensible materials. For the Stahlfolder TX 96 folding system, the PFX-feeder is the start of a perfectly matched folder for highest productivity.

Modular control concept: your key to profitability

The machine control system of the Stahlfolder TX 96 folding system supports the operator at all operations via the ergonomic touchscreen at the feeder. The operator has full access to the job management and the storage for repeat data.

The set-up assistant leads the operator through the individual steps of the job changeover process and provides graphical hints for the setting of required machine components.

Advantages of system configuration

Due to the given machine assembly of a Stahlfolder TX 96 folding system, neither the second fold unit nor the delivery must be removed in case of a job change. All necessary creasing and trimming tools are already included in the machine and are simply activated as required.

With the TX 96 buckle plate unit and the pneumatic twin-lay device it is possible to process the shingled sheet stream of the feeder in the fold unit as well. This is the only way to make use of the productivity advantage of the shingled feeding throughout the whole folding machine up to the delivery. Thus with maximum overlapping in the fold unit it is possible to fold a total of 50 % more sheets in the same time and at the same mechanical speed. After the first fold the sheets are carried on with a sheet gap as usual. Before entering the second fold unit, the pneumatic twin-lay device ensures that the sheet stream is divided into two parallel sheet streams. Moreover the adapted machine speed of the second fold unit ensures stable production conditions and optimum fold quality.

Top fold accuracy and mark-free sheet guidance: the right folding roller technology for precise folding results

Perfect Grip folding roller technology

The innovative Perfect Grip folding roller technology ensures outstanding folding results over the entire length - without compromise. They are less prone to wear and require less maintenance than previous folding roller variants. In addition, the ideal setting range for the folding roller gap is up to two times greater. This makes them more forgiving and reduces set-up times, particularly on manual folding machines, but also on automated folding machines.

The Stahlfolder TX 96 is equipped with Perfect Grip folding rollers as standard.

Motor-driven folding roller adjustment

For an exact adjustment of the gap of folding rollers and slitter shafts, the Stahlfolder TX 96 folding system is equipped with a motor-driven folding roller adjustment. Here, the paper thickness is measured by the integrated sheet thickness measurement at the feeder. A previous piling of paper to feed a learning sheet is not necessary. Therefore, the control system takes over the setting of folding roller gaps and the folding roller traction, considering fold type and paper specification.

Motor-driven combination buckle plates

The first buckle plate of the Stahlfolder TX 96 is equipped with a continuous sheet stop as well as with a continuous buckle-plate lip, ensuring top fold quality.

As a standard, motor-driven combination buckle plates are used. Depending on fold type and format the sheet stops are positioned and – in case of angle adjustments – the fold length is automatically compensated. With every new order an absolute parallelism of the sheet stops – even in deflector position – is guaranteed. All important buckle plate adjustments like clearance, buckle space, and pre-tension of the lower buckle-plate lip can also be done with running production.

Slitter shafts before and after the fold unit: processing like creasing, perforating and cutting

Standard equipment of the Stahlfolder TX 96 folding system in the 1st fold unit is a single front-mounted pair of slitter shafts and a double rear-mounted pair of slitter shafts with lift function. All necessary tools are already included in the folding machine. The easy activating of the required tools allows for a quick change-over of the folder depending on the fold type.

The 45-degree undercarriage ensures with the compact construction of the Stahlfolder TX 96 folding system that all operating elements can be reached easily and in an operator-friendly way. The second fold unit can be moved very easily, e.g. to adjust slitter shafts. Over the carriage rails, it slides precisely back into its production position.

After the first folding unit the shortened sheets are carried on with sheet gap as usual. Before entering the second folding unit, the pneumatic twin-lay device ensures that the very close sheet stream is divided into two parallel sheet streams. Moreover the adapted machine speed of the second fold unit ensures stable production conditions and optimum fold quality.

High-capacity delivery to guarantee your productivity

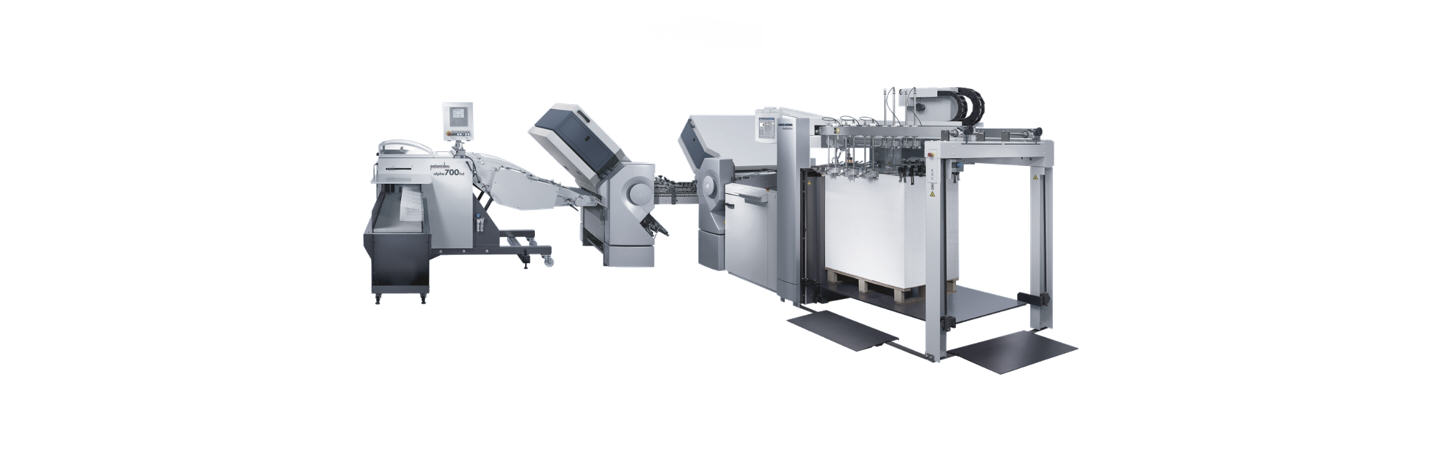

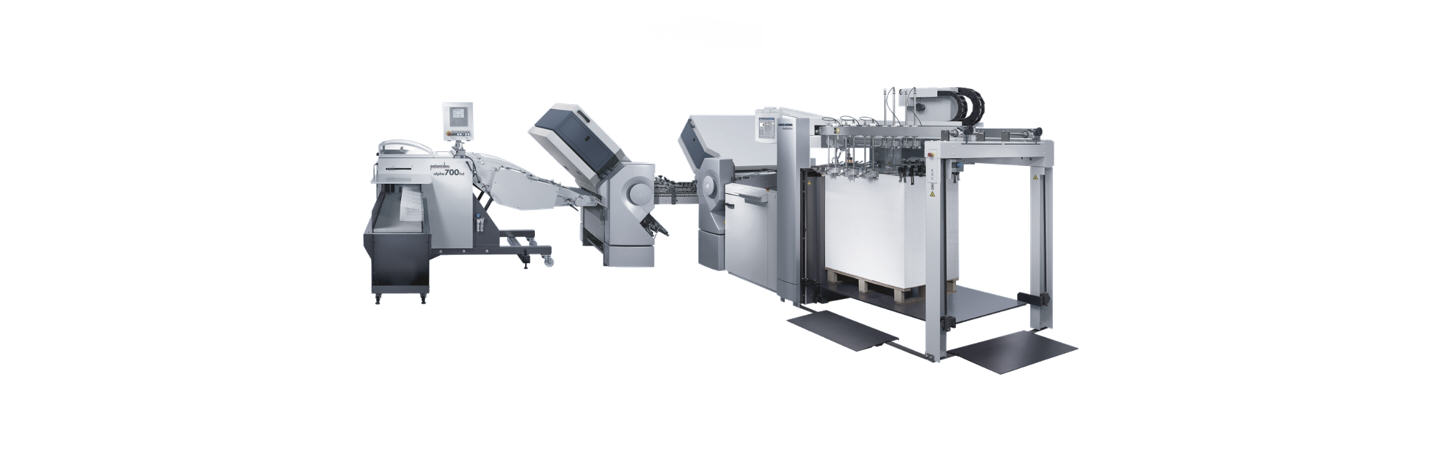

The Palamides alpha hd 70 is a delivery matched to the Stahlfolder TX 96 folding system to process signatures. The fold products are pressed by the machine, gathered, piled and afterwards conveyed to the buffering table neatly jogged. The operating staff can take out the neatly aligned stacks from an ergonomically favorable working height. At the same time, it maintains high productive capacities.

The alpha hd delivers mark-free for the set-up time.

Alternatively, the brand new Stahlfolder P-Stacker can be positioned behind the delivery, which takes over the stacking of the signature packages completely autonomously. This even makes it possible to operate up to two TX 96 folding systems with one operator.

With its unrivaled level of automation, the

Stahlfolder KH 82 is our best-selling

folding machine.