Our maintenance programs improve productivity and cut unanticipated down-time. They cover basic technical condition checks, fine-tuning your press and, if required, replacing wear parts. We supply you with a final assessment based on the maintenance we have carried out. This provides transparency in terms of your press's technical condition and if necessary, suggestions for additional preventive measures. This helps you to improve performance and throughput, safeguards your investment and maintains resale value.

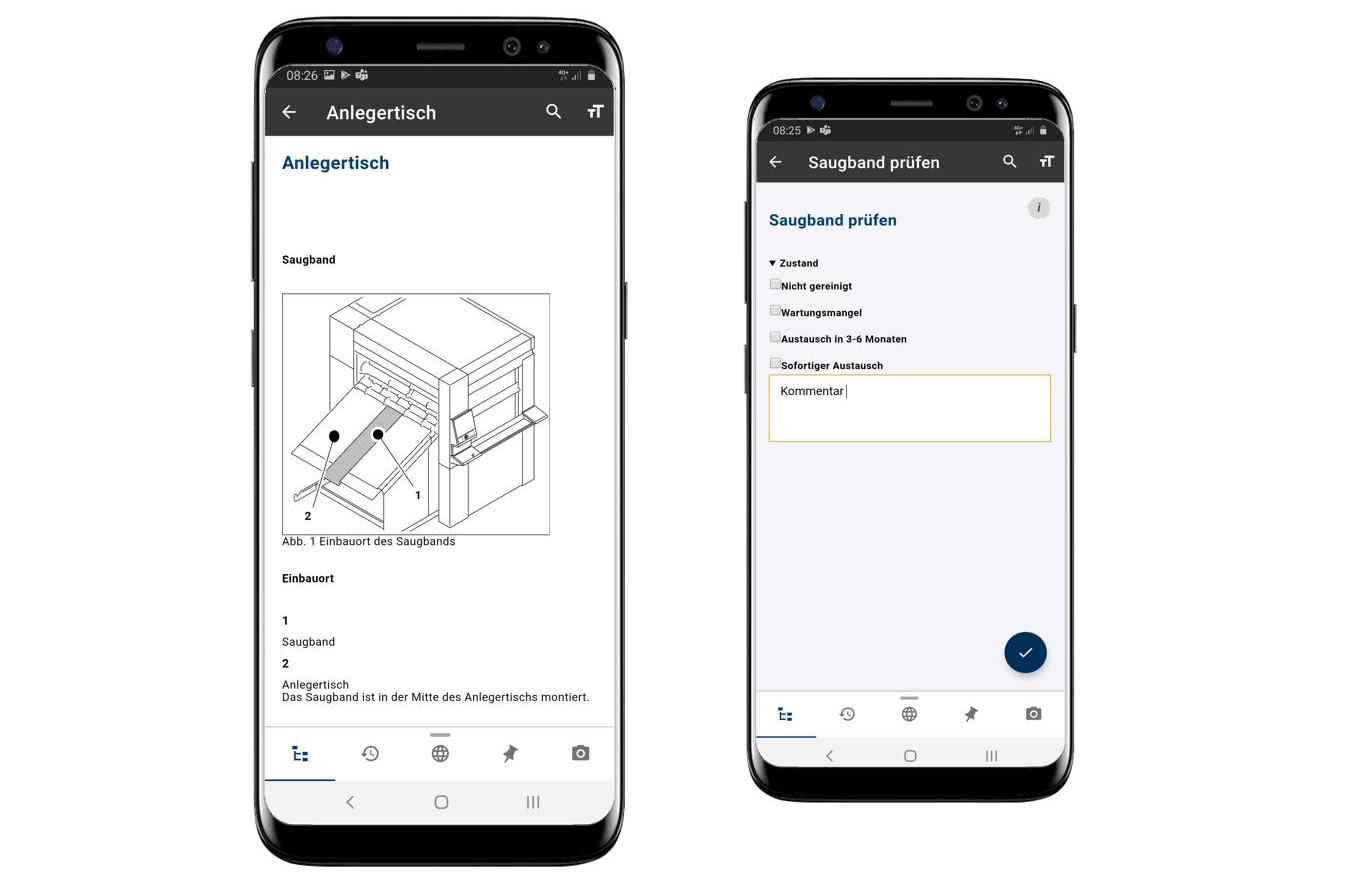

Machine Check - Keep your machine running smoothly with regular inspections using our standardized checklists. By evaluating system performance and settings, and recommending replacement of worn parts, we offer quick, straightforward solutions to enhance productivity and prevent downtime.

Preventative Parts Packages - Maintain consistent print production and maximize throughput with our preventative maintenance and parts packages. After a thorough assessment of your system’s technical condition, we’ll provide tailored recommendations and suggest any necessary preventative measures to improve machine availability and minimize unexpected downtime.

POLAR Maintenance Kits - Maintaining your POLAR Cutter is now simpler than ever. We created a specially designed kit that includes all the essential wear-and-tear parts to keep your cutter operating at peak efficiency.

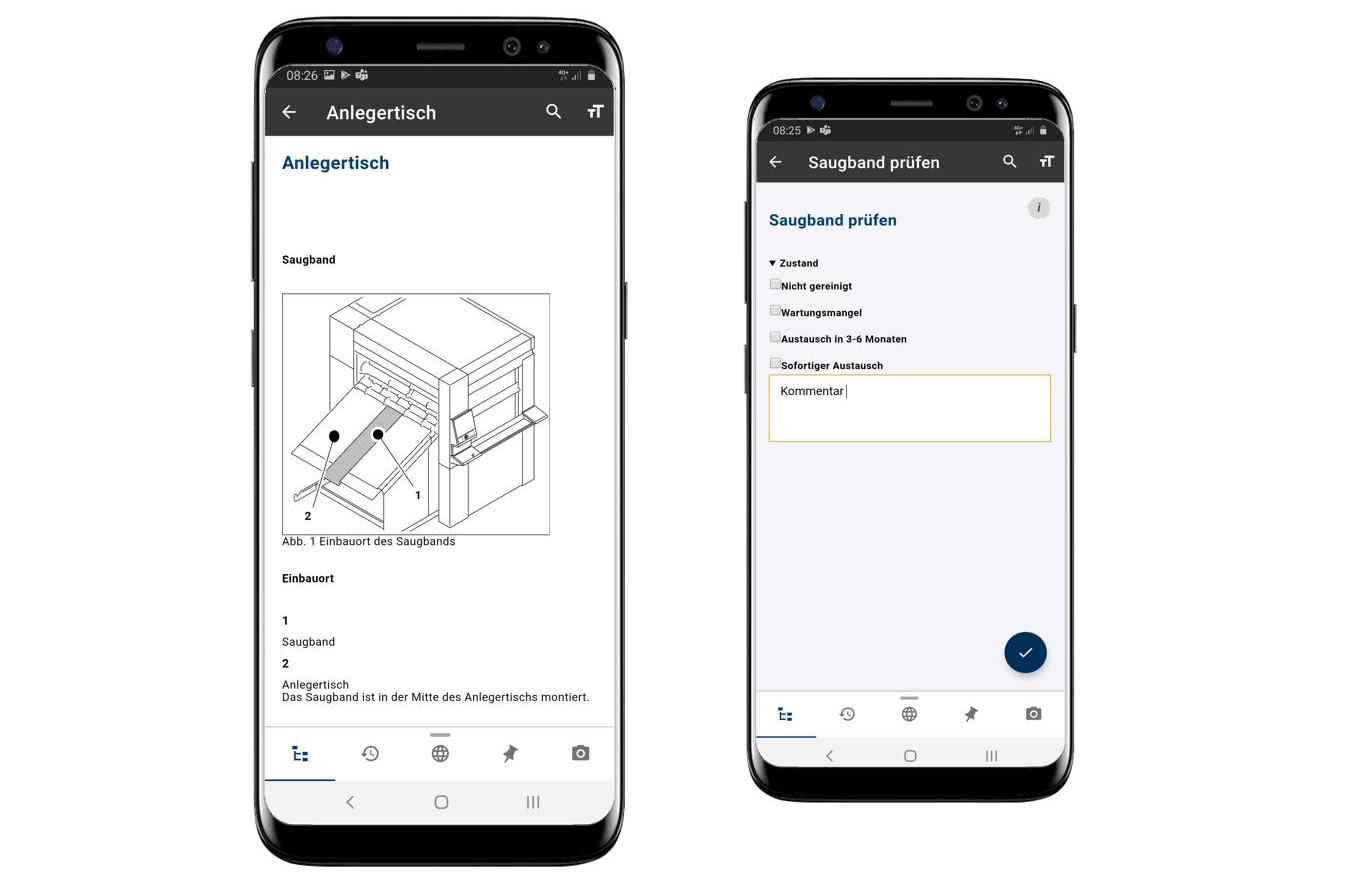

The Maintenance Manager ensures all members of the maintenance team have access to the exact information they need to maximize machine availability with the minimum of effort.

Whether you need urgent support, spare parts or technical advice, please do not hesitate to contact us.