At speeds of up to 7,500 sheets per hour and a cutting pressure of 300 metric tons, this machine offers solutions for a wide range of applications and material types.

With an output of 7,700 sheets per hour and short set-up times, the Easymatrix 106 C/CS die-cutting system stands for productivity and cost-effectiveness up to the 106 format. It processes materials from 90 to 2,000 g/m². Even corrugated board up to 4 mm thickness can be processed.

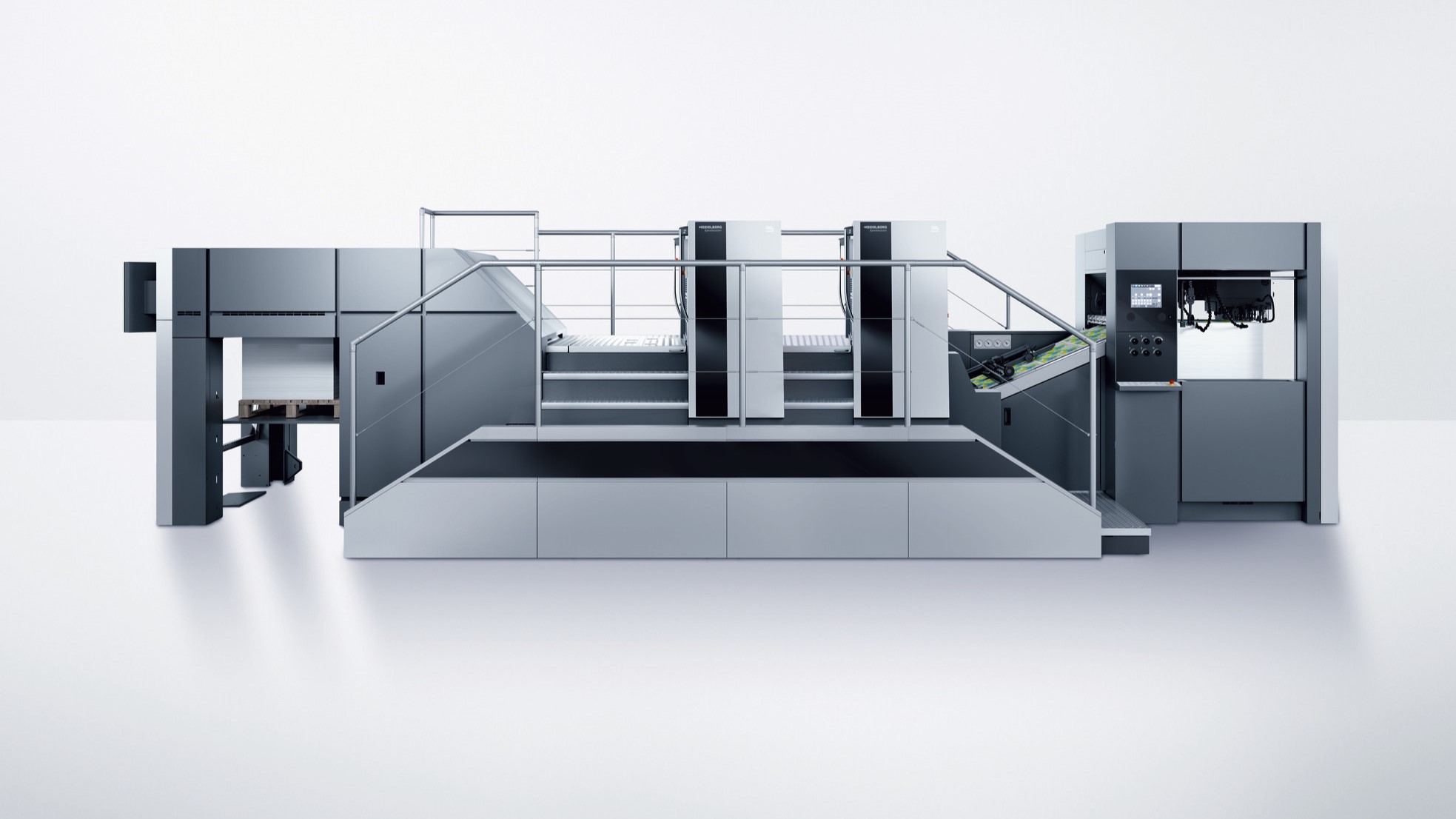

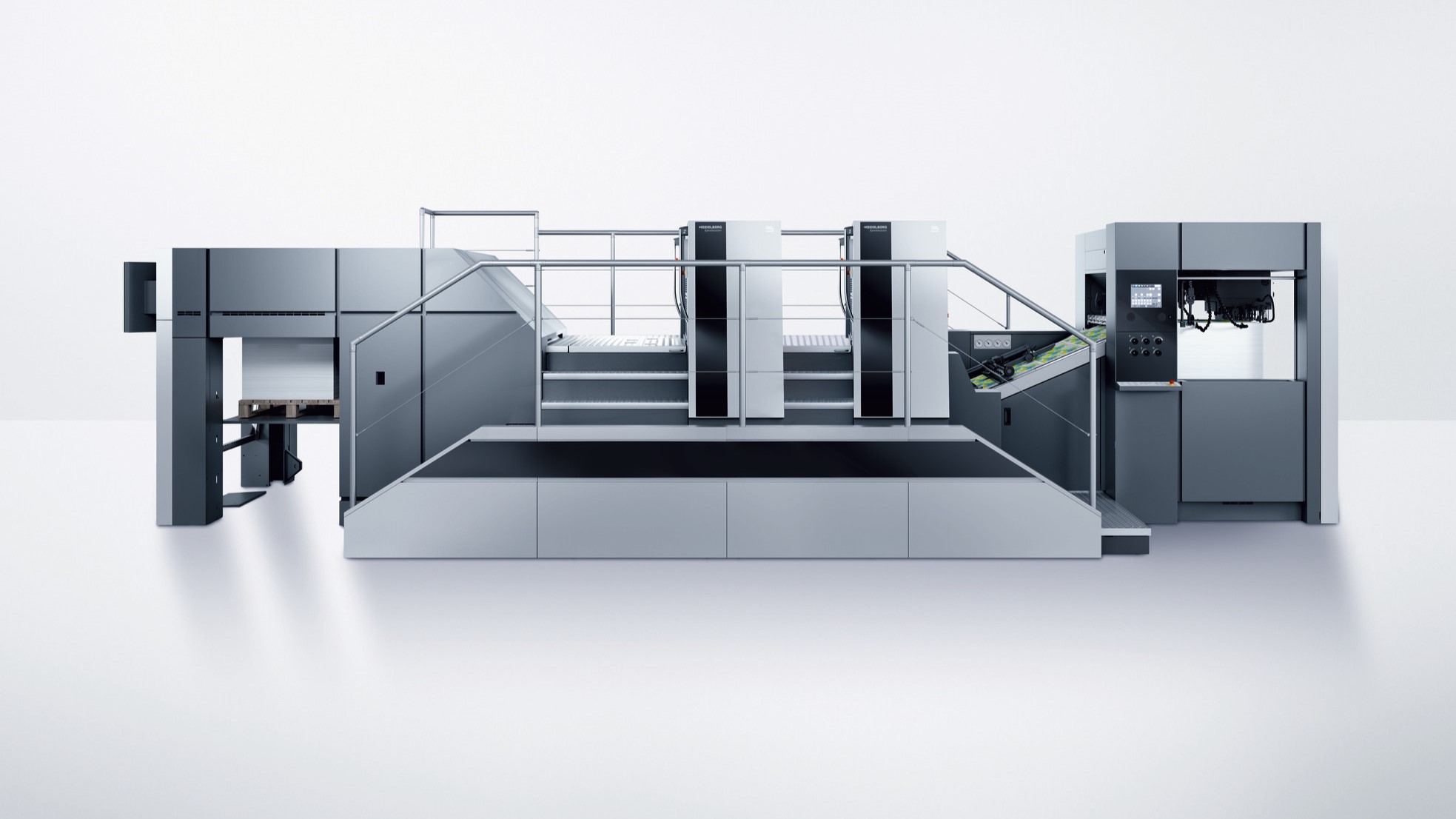

The Promatrix 106 CS die-cutting and embossing system captivates with precision in folding carton production. With an output of 8,000 sheets per hour and short set-up times, it stands for productivity and cost-effectiveness up to the 106 format. It processes materials from 90 to 2,000 gsm. Even corrugated board up to 4 mm thickness can be processed.

The Promatrix 106 CSB is fully equipped to consistently perform in demanding folding box production plants. It is particularly suited for companies looking to reduce their manufacturing costs and shorten production time by eliminating manual operations - as well as for established packaging printers already producing on an industrial scale who need to increase capacity or replace obsolete equipment.

The Mastermatrix 106 CSB has been specifically optimized for higher machine speed (max. 9,000 sheets per hour), greater productivity, and shorter makeready times.

The Ecocut 170 CS flatbed die cutter was specially designed for large-format corrugated cardboard and laminated cardboard. It processes sheet formats up to 1,260 x 1,700 mm, achieves a top speed of 6,000 sheets/hour, and processes materials from 1.0 to 8.5 mm thick – for precise and productive die cutting and stripping.

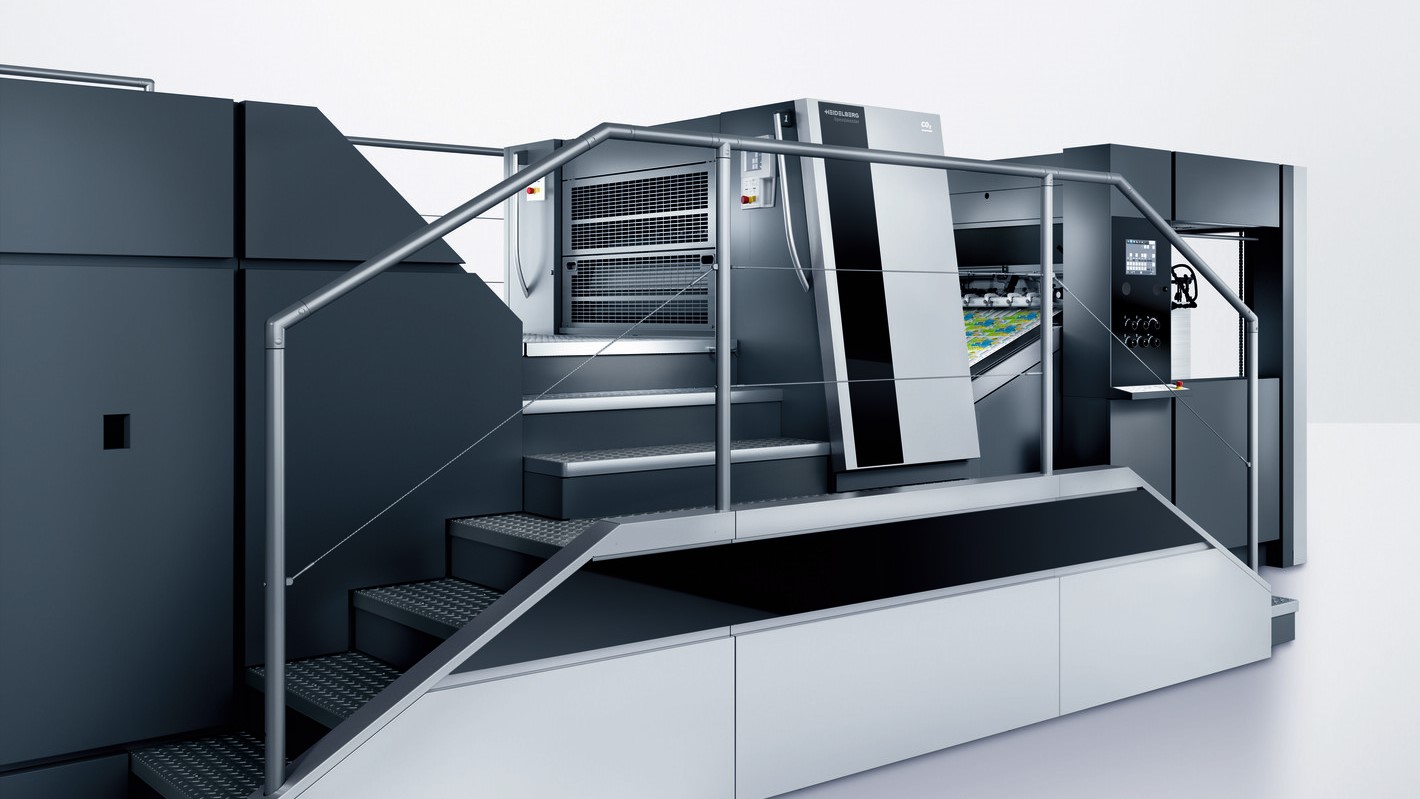

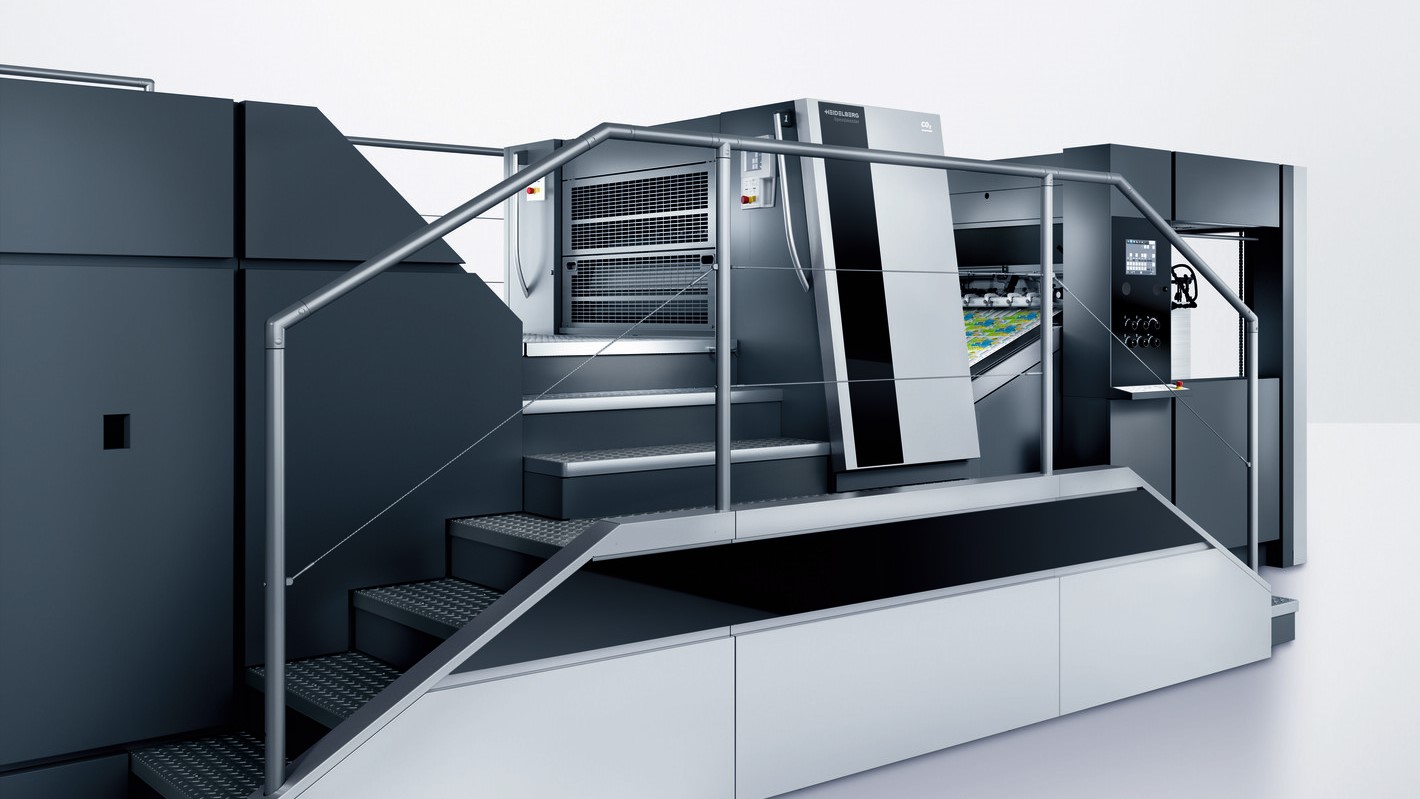

The Speedmaster 106-DD twin-unit die-cutter combines another important production step in a single operation. The first unit places the injection hole with extreme precision by means of a die on a magnetic cylinder. Even the tiniest holes of five millimeters diameter are possible. The waste is reliably removed by an additional extraction system.

The compact Speedmaster XL 106-D single-unit die cutter boasts a small footprint and low investment costs. With the Speedmaster XL 106-D/DD, you benefit from maximum stability and cut quality. It is the combination of new optimized side walls, stiffer die-cutting cylinders, reinforced bearings and improved anti-static devices on the feeder and delivery that ensures optimized sheet travel and thus high production speeds of up to 10,000 sheets per hour.

The Kawahara TXS-1100 is the perfect entry-level machine for label and folding carton postpress because of how easy it is to use. It combines consistently high blanking quality and productivity with maximum flexibility for a wide range of blank shapes. With its wide range of materials, it addresses both in-mold label printers and folding carton printers.