HEIDELBERG offers users in the packaging and commercial sector a comprehensive range of solutions along the entire value chain, from platesetters to customized printing presses and finishing systems. However, it is only with the integrated "Prinect" software that the philosophy of a complete solution provider becomes reality. With Prinect, HEIDELBERG has established a benchmark in the industry: Around 60 per cent of HEIDELBERG customers worldwide now use the software.

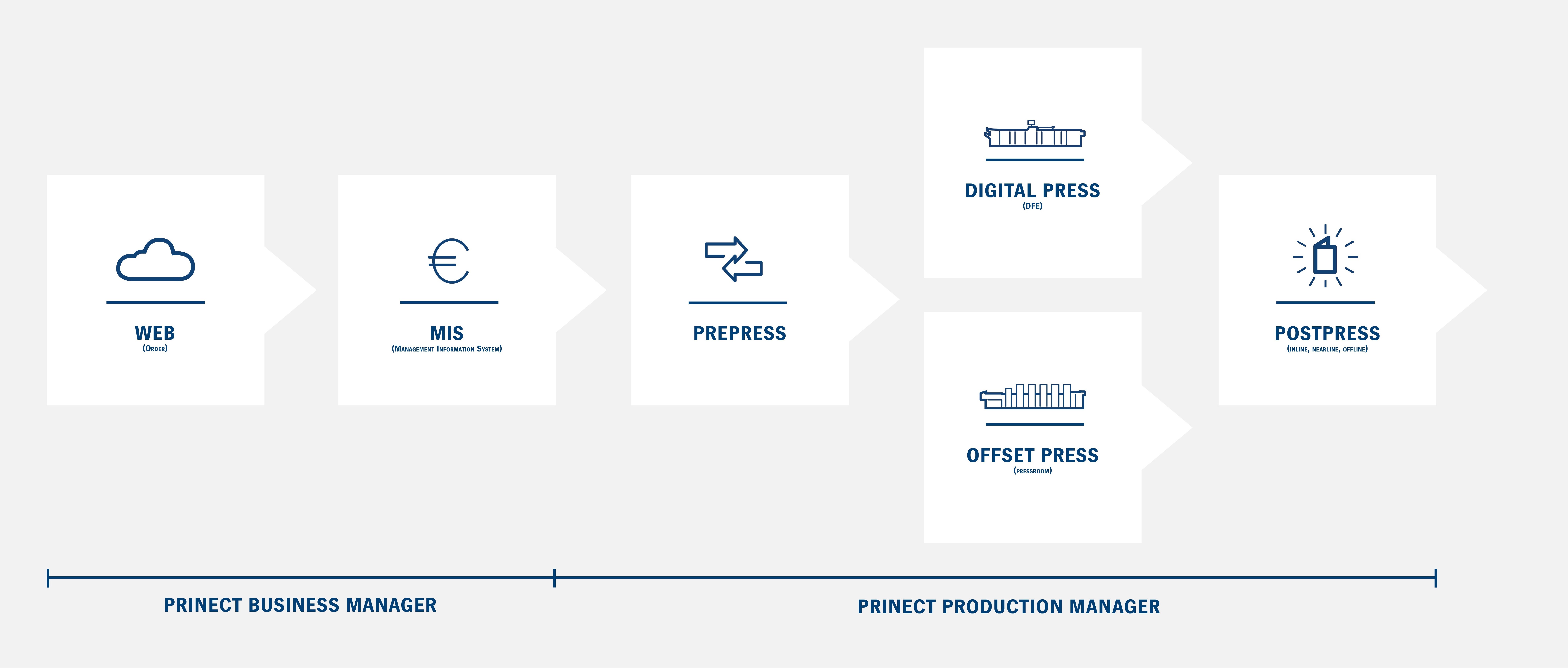

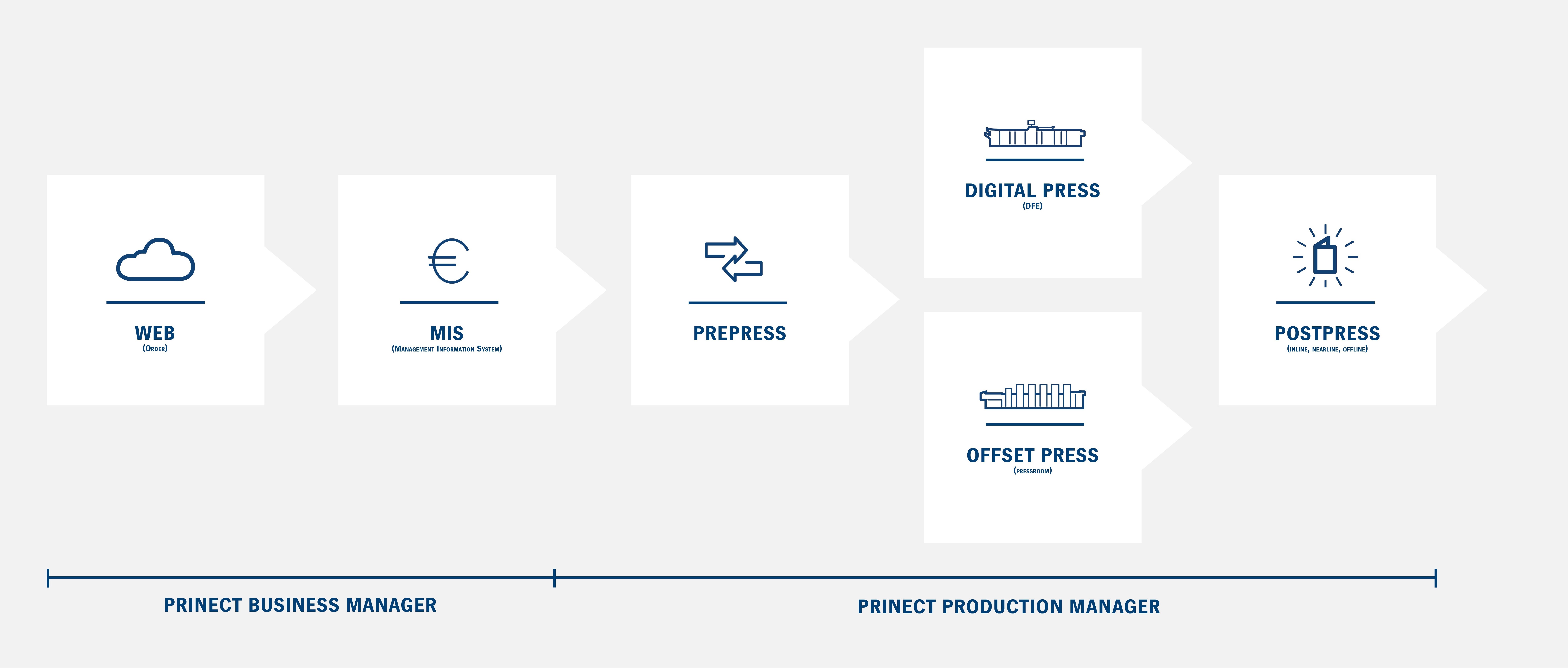

Prinect supports print shops from quotation calculation and production planning through prepress processes to the setting specifications for presses and postpress systems. One of Prinect key system benefits is the reduction of touchpoints and the elimination of multiple entries. Once entered into the system, a print job runs through the production process without any further manual processing steps. Once information has been entered, it is always communicated to the correct recipient - making duplicate entries and errors a thing of the past.

Only Prinect software from HEIDELBERG offers a comprehensive level of integration across the entire value chain of a print shop. The digitalized process chain saves time and costs, avoids operating errors, reduces waste and energy consumption, and thus makes an important contribution to more sustainable production of print products.

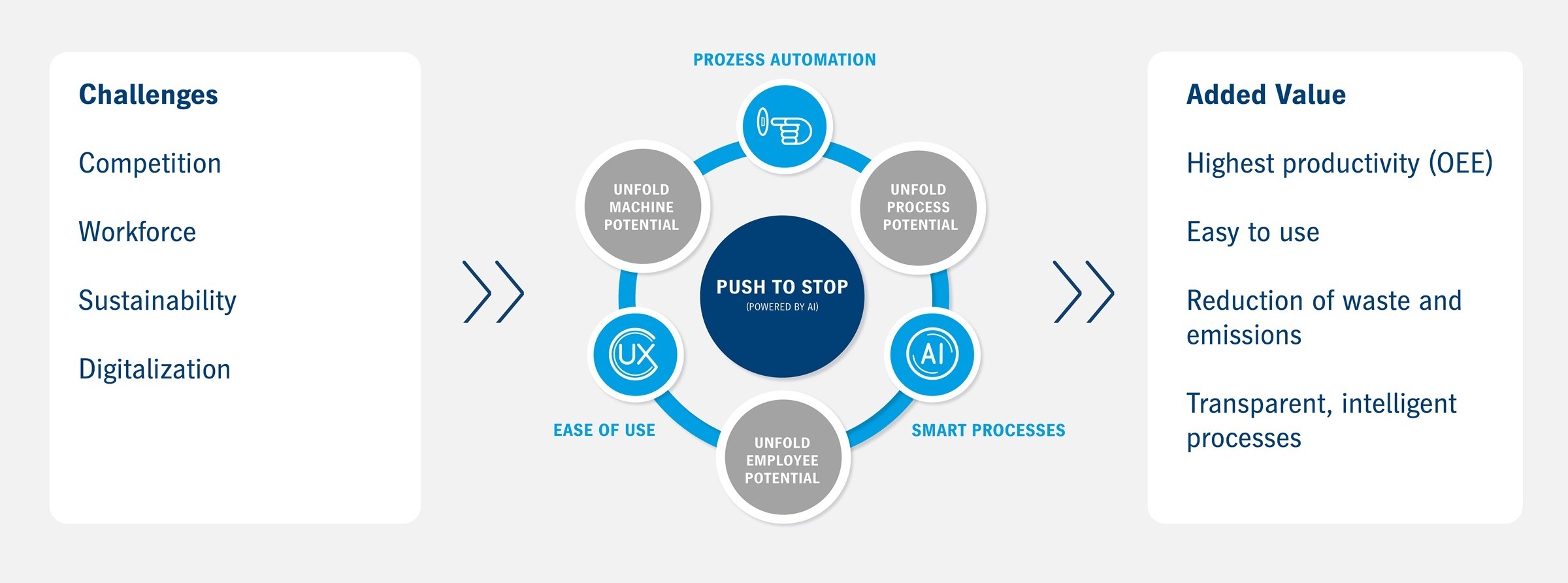

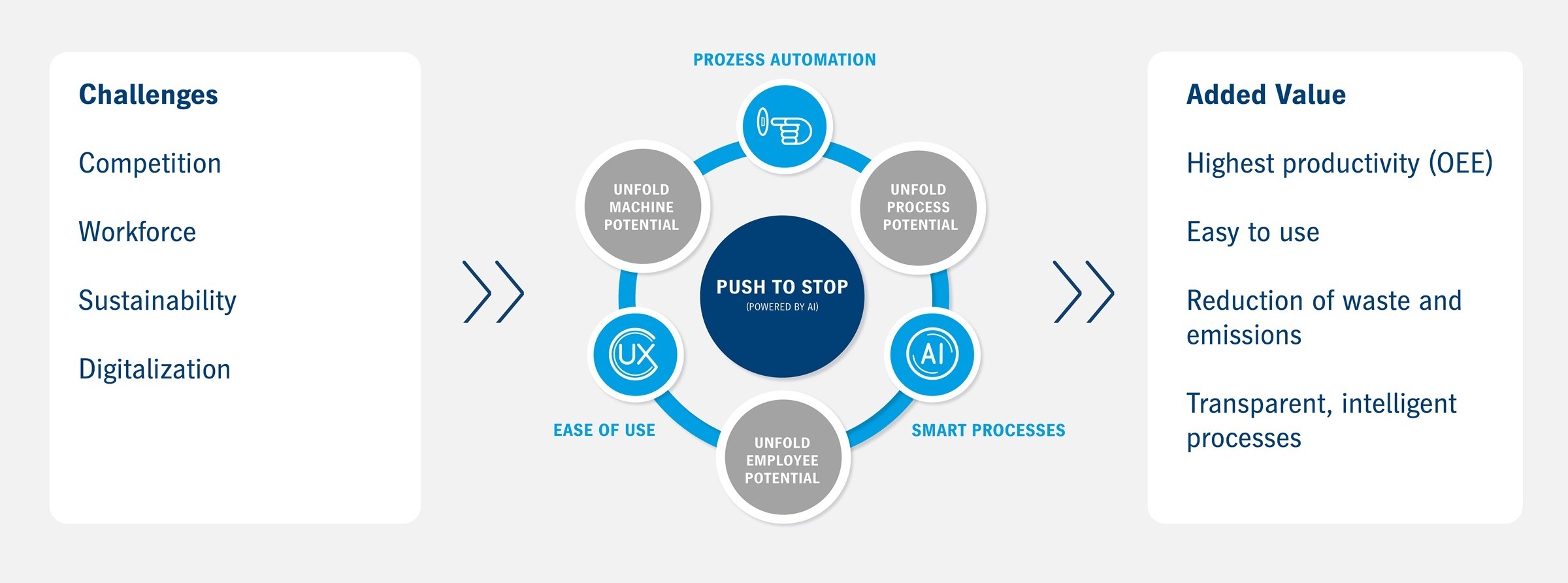

With increasing cost and competitive pressure and a shortage of labor, more and more companies are turning to fully digitized, autonomous print production with the Push to Stop concept from HEIDELBERG to reduce the cost per printed sheet. The Prinect architecture is the prerequisite for autonomous printing. It ensures the continuous flow of data in the production process and supplies the numerous assistance systems in the press with the required information.

At the upcoming drupa, HEIDELBERG will be presenting the enhanced Push to Stop concept in conjunction with the world premiere of the new Peak Performance Speedmaster XL 106. The digital innovations with Prinect will show how multiple work steps can be replaced and how Push to Stop takes automation to the next level of productivity through the increasing use of artificial intelligence. Thanks to Prinect, autonomous print production in conjunction with the new Peak Performance generation is now also possible in packaging printing. HEIDELBERG expects this to increase overall productivity for packaging customers by up to 20 per cent.

The Prinect Production Manager is of crucial importance for customers in production operations, as it is responsible for the automation of production processes, color and quality management, as well as reporting. The advantage is that it is available as a subscription service and customers only pay for the functions they actually need. Users also benefit from always having the latest version. This makes the tool an attractive offer for print shops regardless of the size of their business.

Another USP of HEIDELBERG in terms of software expertise is the integration of offset and digital printing into a continuous workflow via the Prinect Digital Frontend. The automated calculation of a print job in prepress determines which output device - offset or digital printing - is the most cost-effective and the job is fed into production accordingly via Prinect.

With the Prinect Business Analytics Apps - a tool for efficiency comparisons and data-based decisions - and the Service Apps, which increase the availability of the machine park, HEIDELBERG is now opening the door to cloud-based software solutions. HEIDELBERG is working with an established partner whose server infrastructure is installed in Germany in accordance with European law. In these service solutions, software is not stored on servers in the print shops or at HEIDELBERG but is provided via a high-performance platform. The advantages for users are obvious: They do not have to invest in their own hardware, IT staff or maintenance work. They can customize computing power and storage space to their individual needs and always work with the latest software versions, as updates are rolled out automatically.

The cloud-based apps also enable new subscription models: Customers can select the applications they need in their business. The Prinect apps and other digital offerings can be obtained via new HEIDELBERG customer portal, the global rollout of which will be completed this year. The declared strategy of HEIDELBERG is to make new software products available in future via this portal and in the form of apps. The portal is accessed via the HEIDELBERG ID, which also defines the user's role and rights. Printing companies can thus specifically define which functions employees have access to. Another advantage: A single login to the account is all that is needed to use all the services that have been activated.