Even with high ink coverages, the LED system designed by HEIDELBERG achieves best curing results of highly reactive LED inks and LED coating applications in sheetfed offset printing.

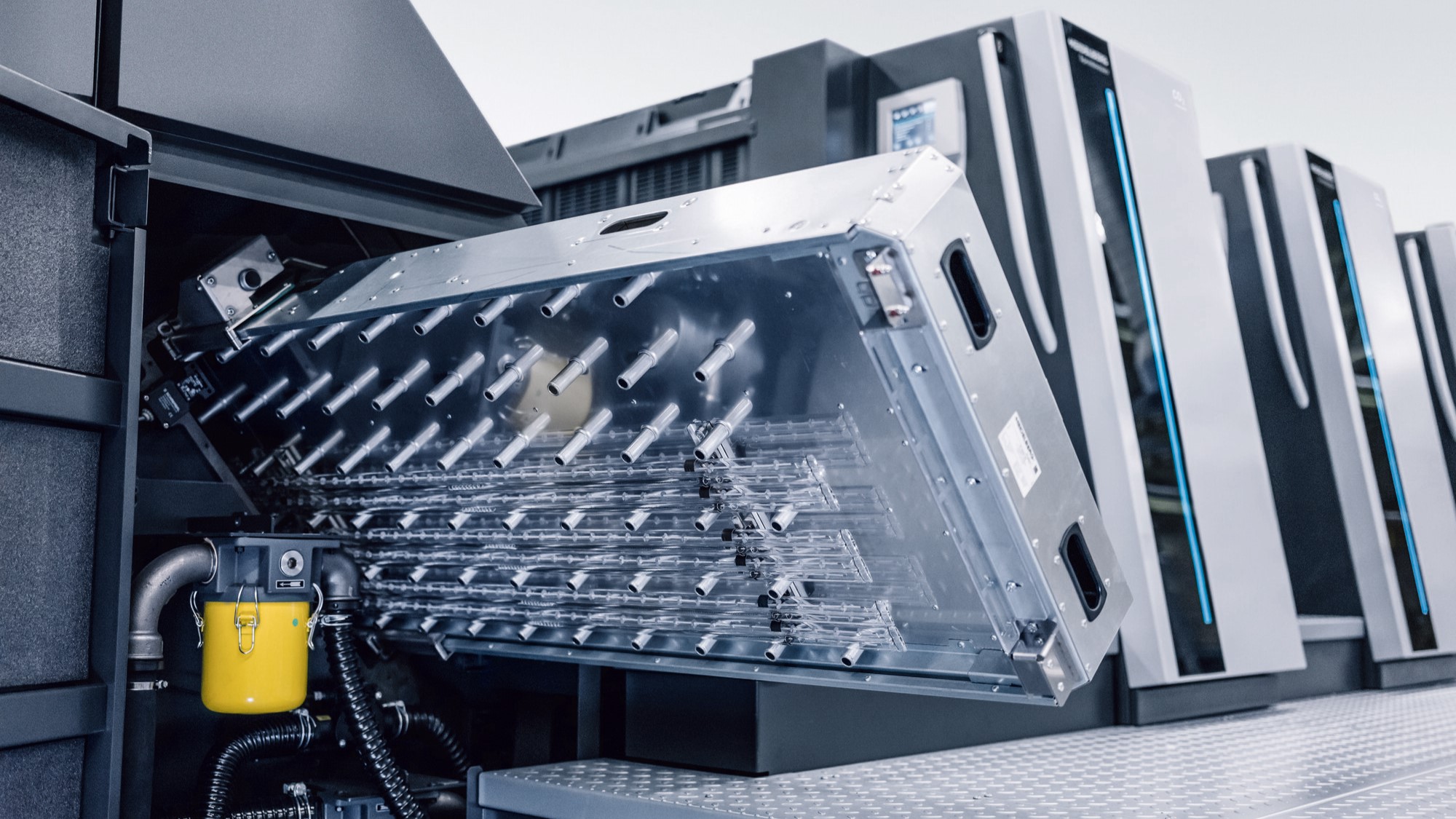

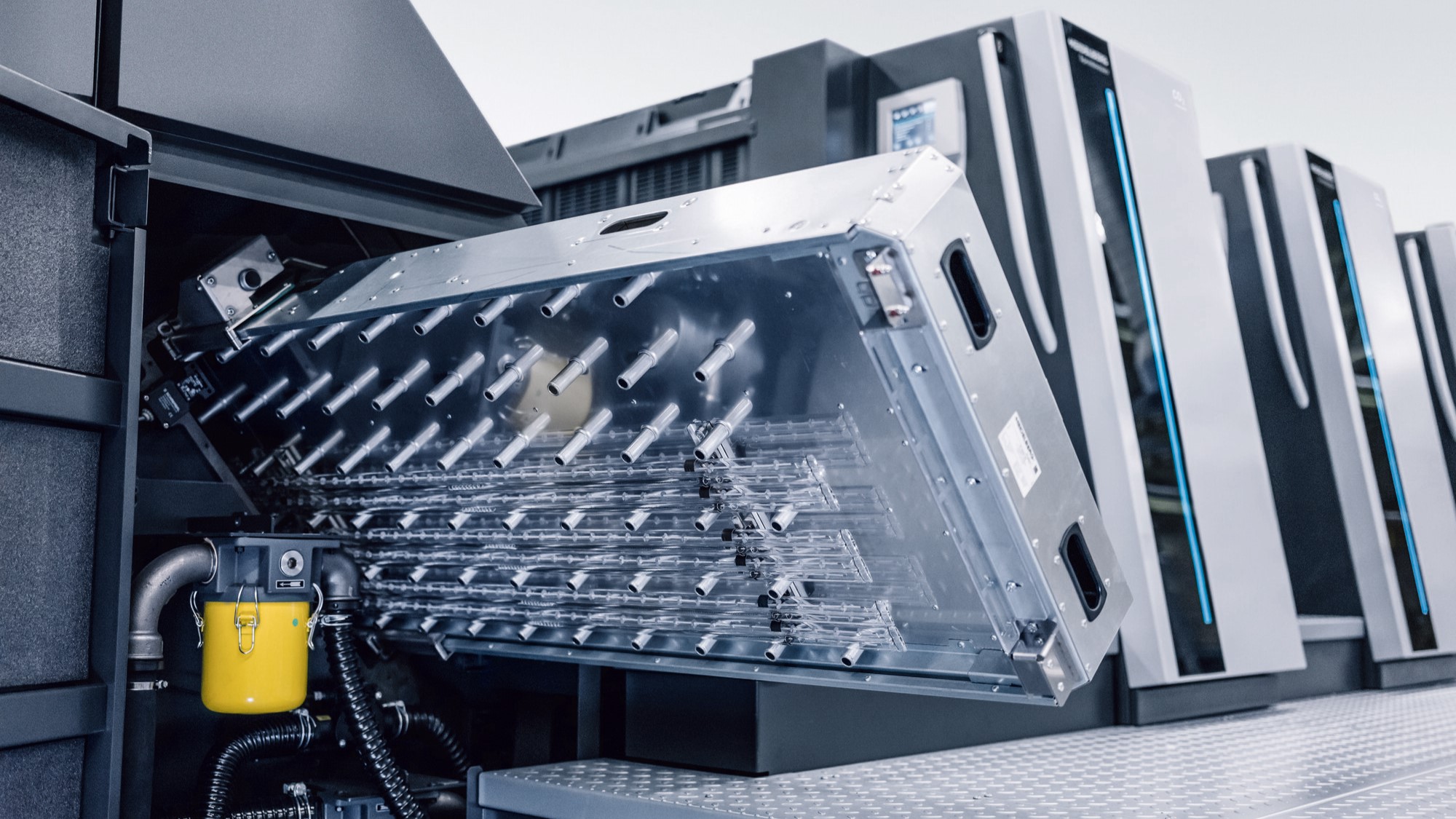

The system runs at lowest energy consumption and still delivers highest performance. During stand-by and make ready it automatically reduces consumption to close to zero. When entering the sheet size at the Prinect Press Center, Auto Format Setting sets all LEDs accordingly in lateral and circumferential direction. This results in additional energy savings of up to 30% during full production.

The emitted light is optimally focused via the double lens technology. The high distance between sheet and the LED-dryer reduces the heat input on the substrate to a minimum and ensures safe sheet travel.

With its DryStar LE (low energy), HEIDELBERG has created a special UV system as an entry-level option for commercial printers who are looking to move into UV printing. The use of highly reactive inks reduces energy consumption and the number of UV lamps required. The DryStar LE UV is based on the tried-and-tested technology of the DryStar UV. The result is impressive quality, rapid curing, and print sheets that require only minimal amounts of powder before being transferred directly to postpress.

The DryStar LE UV is available with one, two or a maximum of three lamps per press configuration. Depending on the job specification, the output of each lamp can be adjusted flexibly between 80 and 200 W/cm. The versatility of the DryStar LE UV makes it a perfect alternative for commercial print shops that are looking to harness the benefits of UV printing so as to improve their response to changed market requirements (uncoated papers, coating effects, very short throughput times).

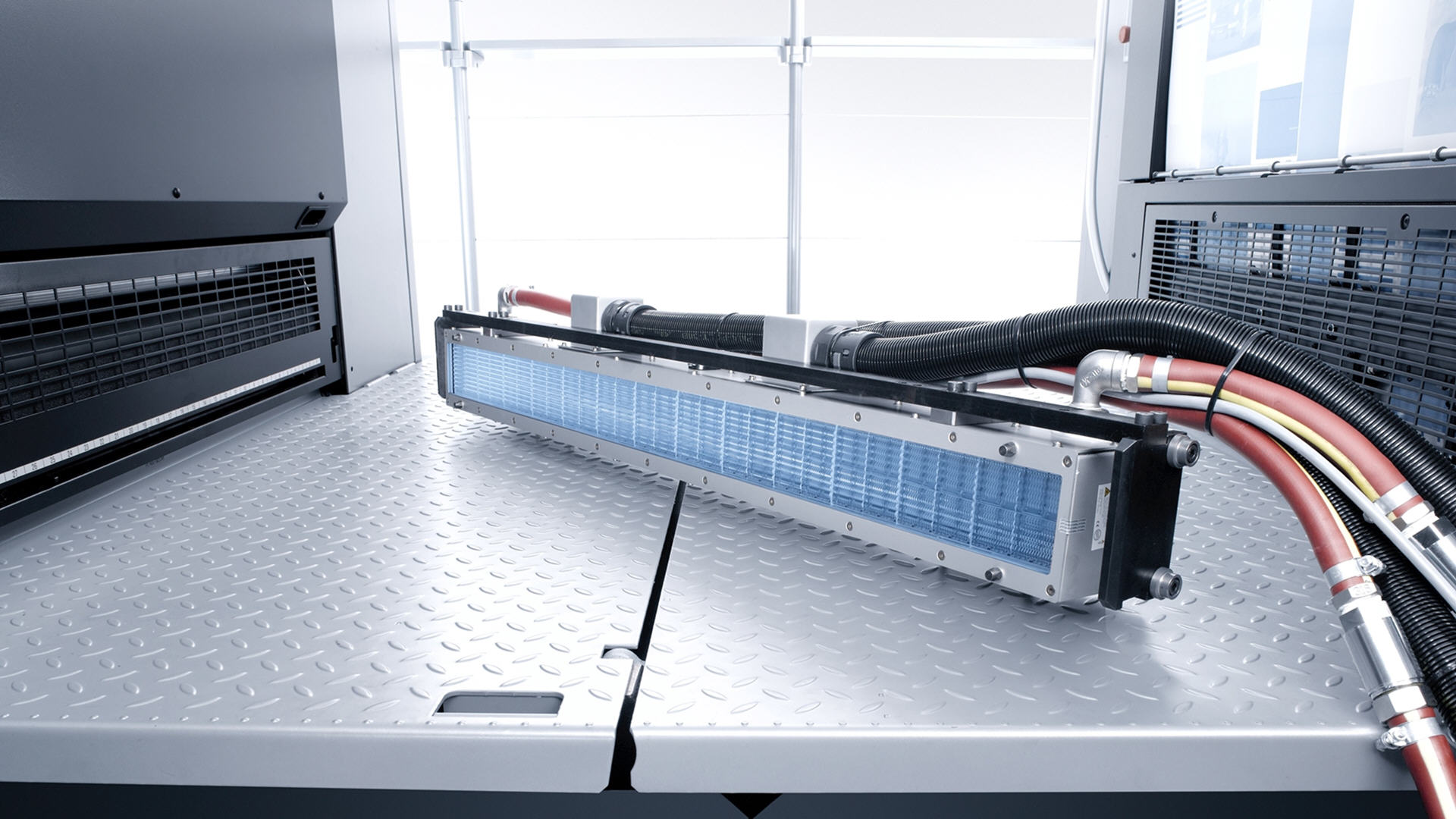

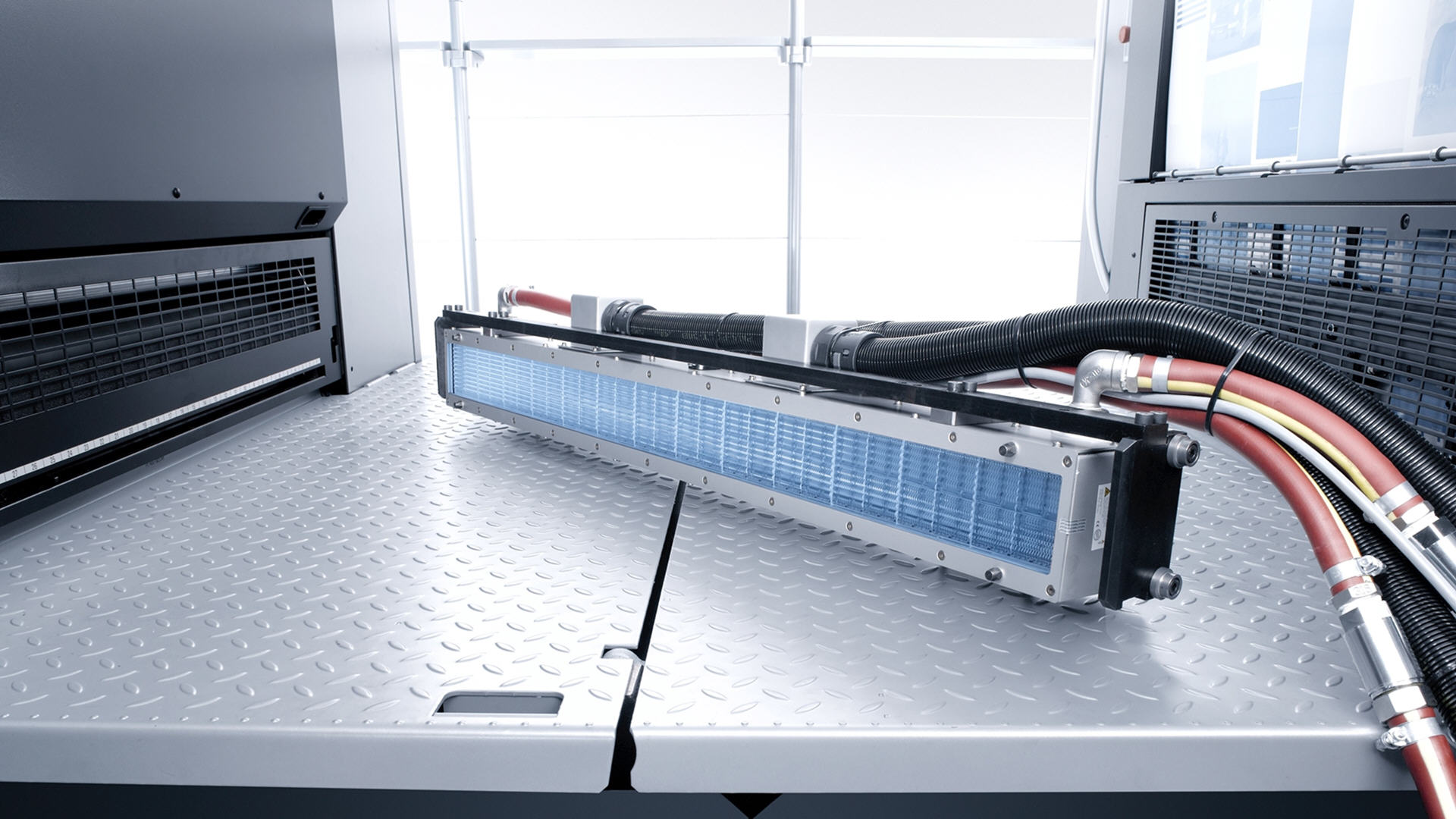

With DryStar UV, the benefits of the DryStar system can also be used in UV printing. Its perfect integration into the press, the very small distance between UV dryer and sheet, and the use of an innovative reflector coating have increased the dryer output significantly. As a result, top production speeds are possible in UV printing, too.

Efficient temperature management ensures that, despite the high output, heat transfer to the printing stock is minimized. This is ideal for sensitive materials and ensures complete register accuracy, even when printing on thin plastic films. A special reflector is used that focuses the UV rays onto the sheet. The heat-inducing IR radiation, on the other hand, is absorbed by cold air from the energy-saving water-cooled cold air generator – for top results in UV printing.

DryStar Ink, DryStar Coating, DryStar Combination, and DryStar LY(Y)L ensure you will find the right dryer for any application. Perfect coordination between sheet travel and dryer optimizes drying and quality, even with maximum machine speeds, high ink coverage or challenging coatings. No other system achieves a comparable level of efficiency. Thanks to this highly effective drying, sheets are available for finishing very quickly.

The energy-efficient dryer saves up to 30 percent energy thanks to optimized energy input, integrated heat recovery and thermal insulation. The high level of insulation reduces energy consumption during drying and minimizes heat loss. The pressroom heats up less. Less air conditioning is required. The workplace becomes more user-friendly.