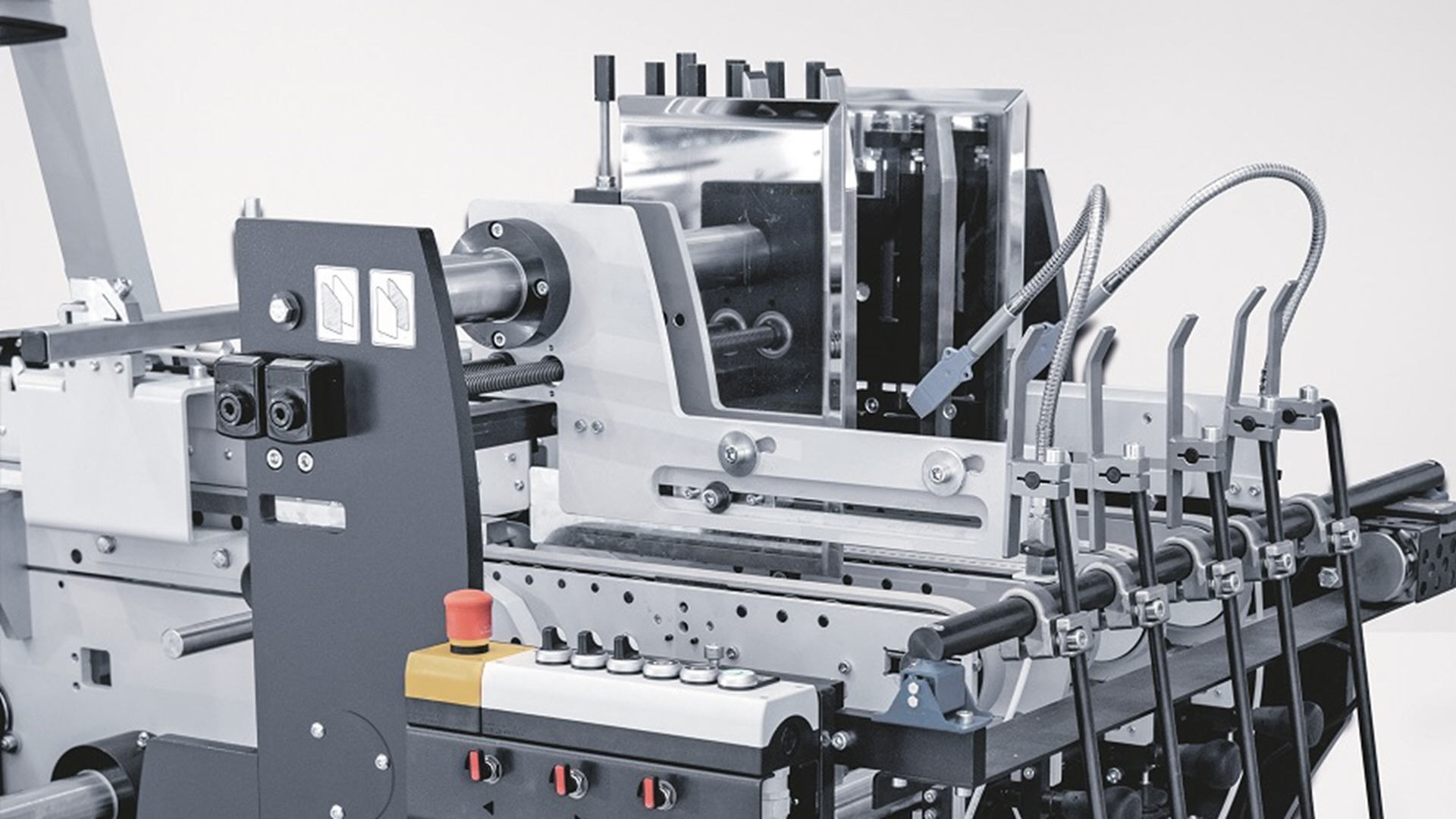

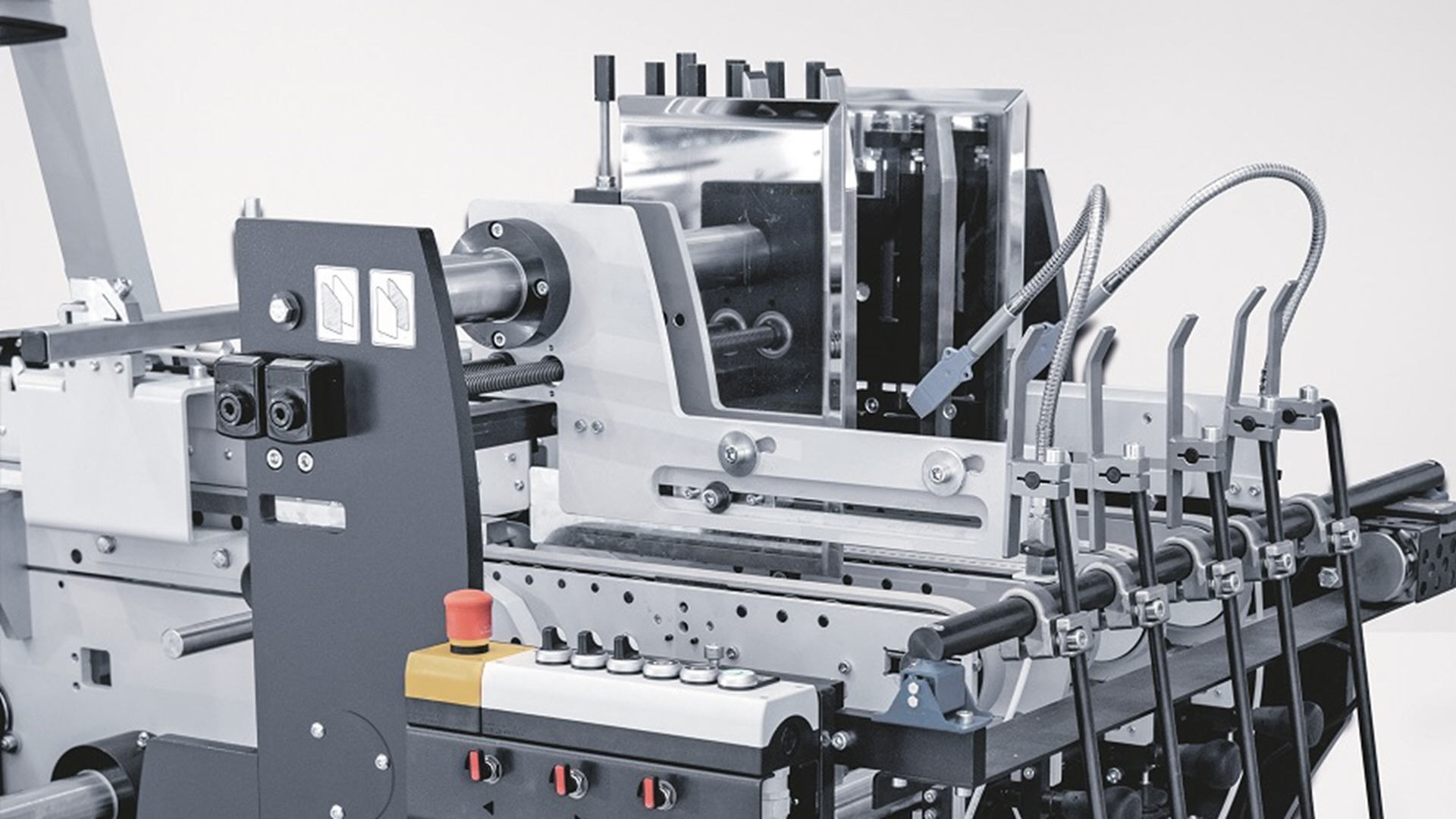

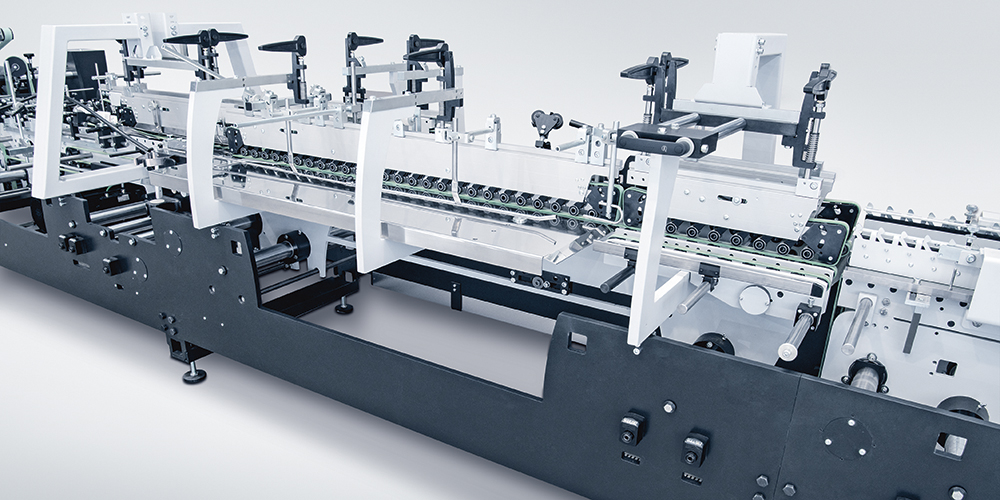

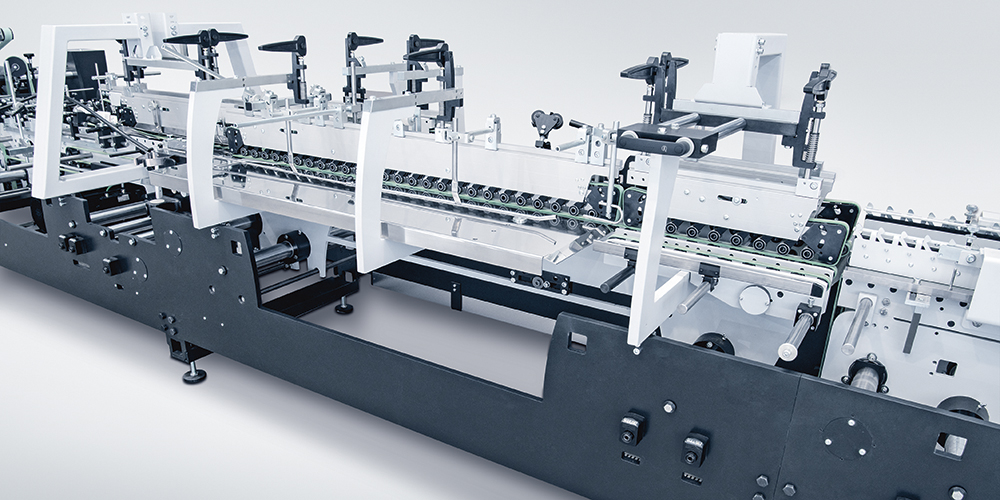

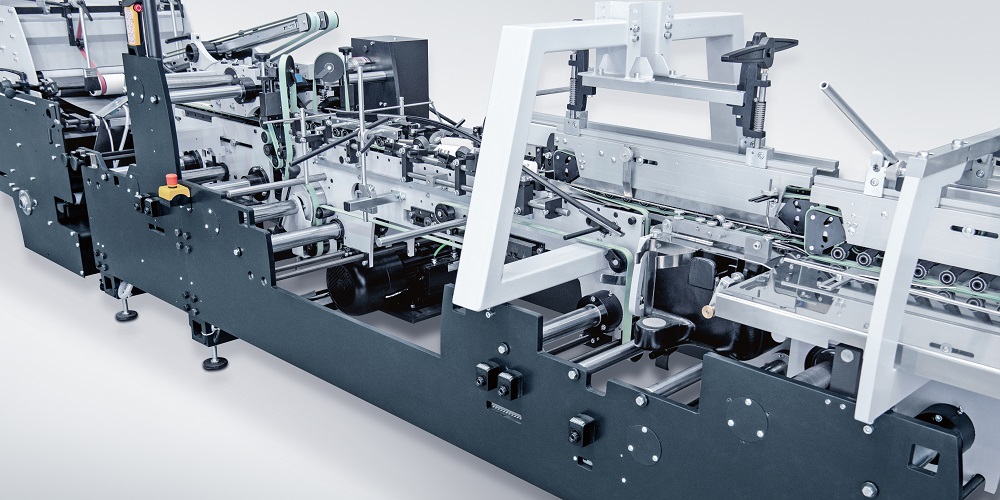

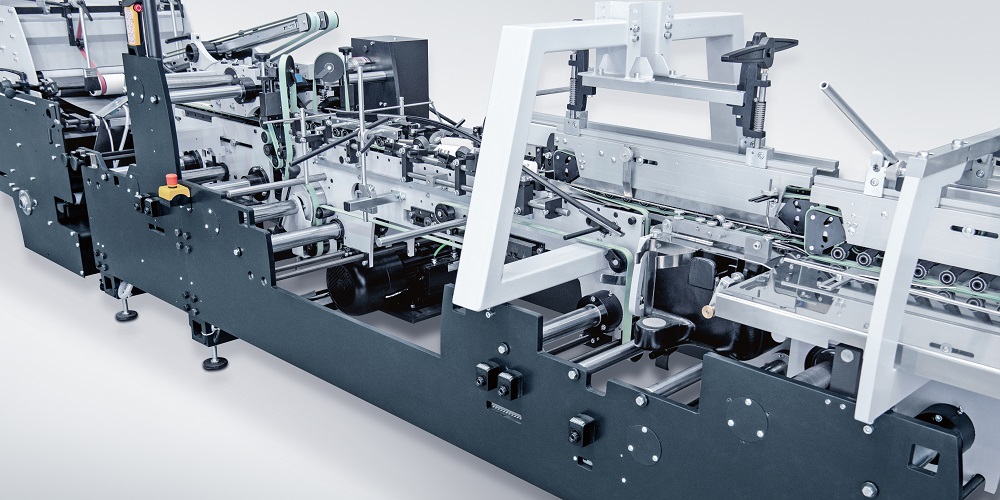

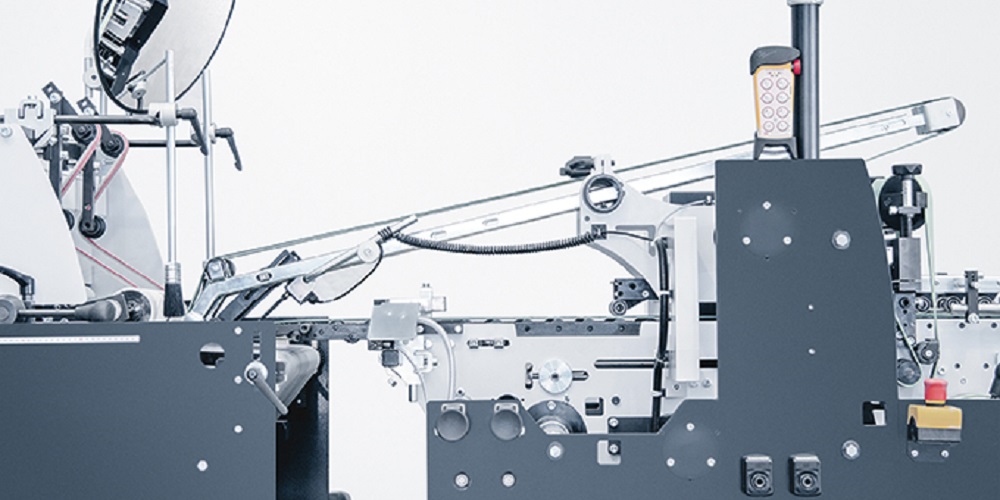

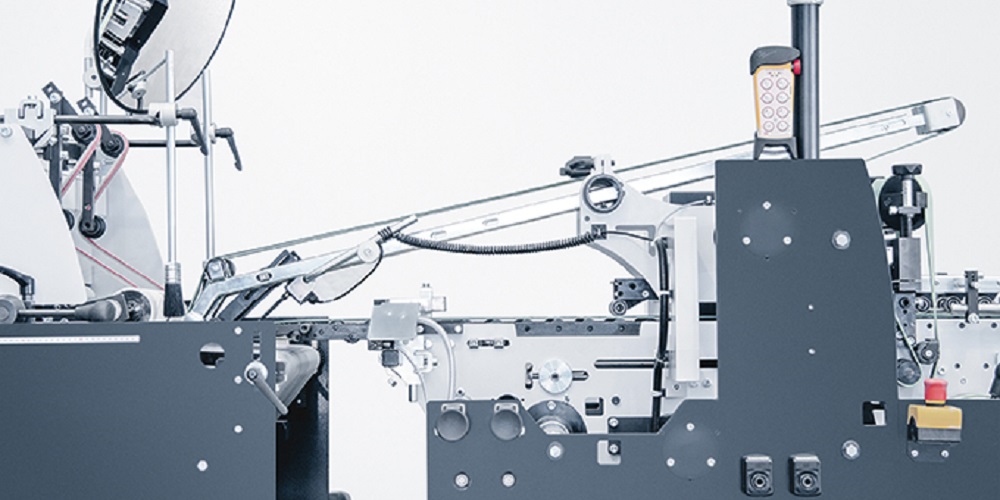

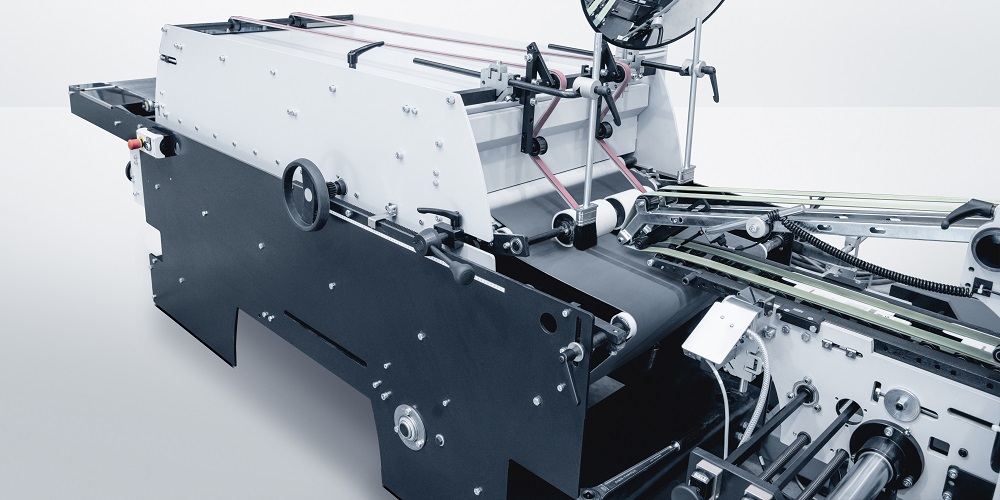

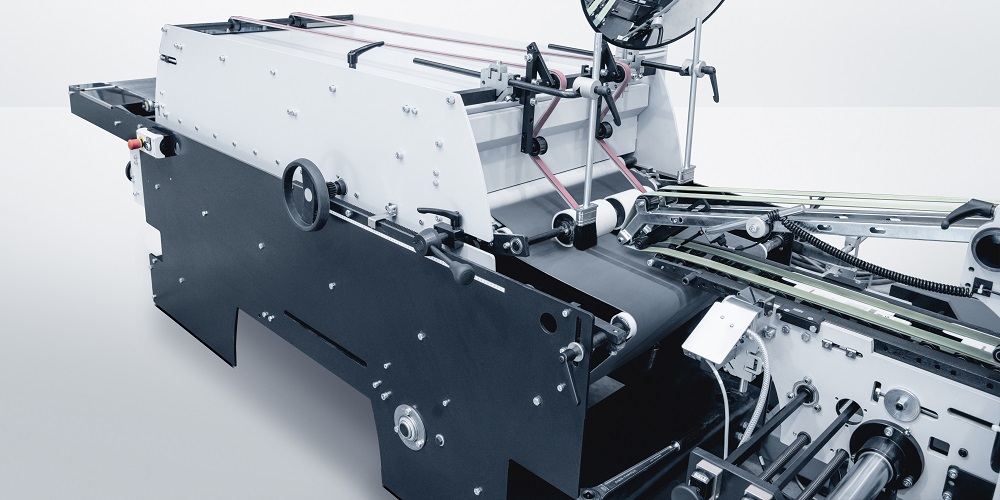

The machine was especially designed in a short layout and finds a suitable place in your production almost everywhere. Its performance of up to 300 m/min is perfect for processing higher production runs. So of course the Diana Go can also be seen as a production supporting machine.

The machine concept allows you to process many types of packaging such as straight line, lock bottom and mailing envelopes from small to large. Masterwork and Heidelberg offer you a folding carton gluing machine with the highest safety standards, proven Diana technology with a certain extra flexibility and an unbeatable price-performance ratio.

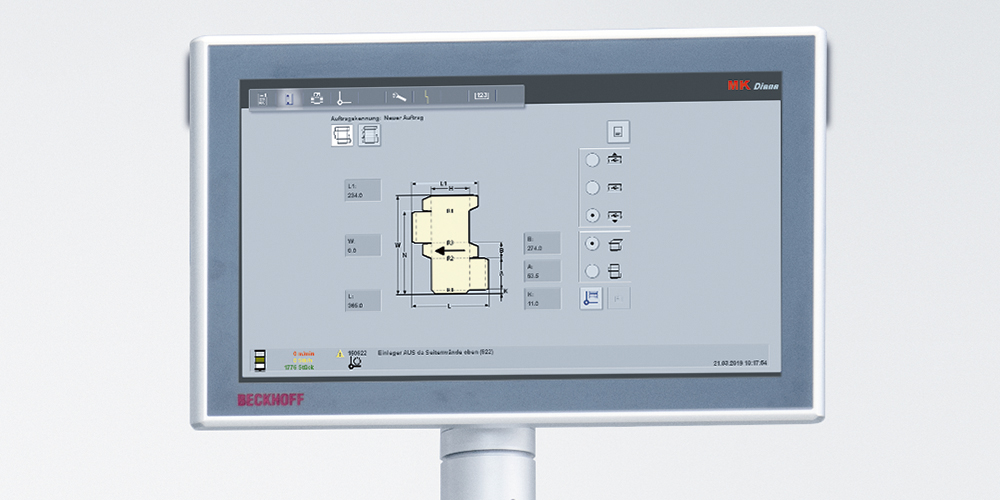

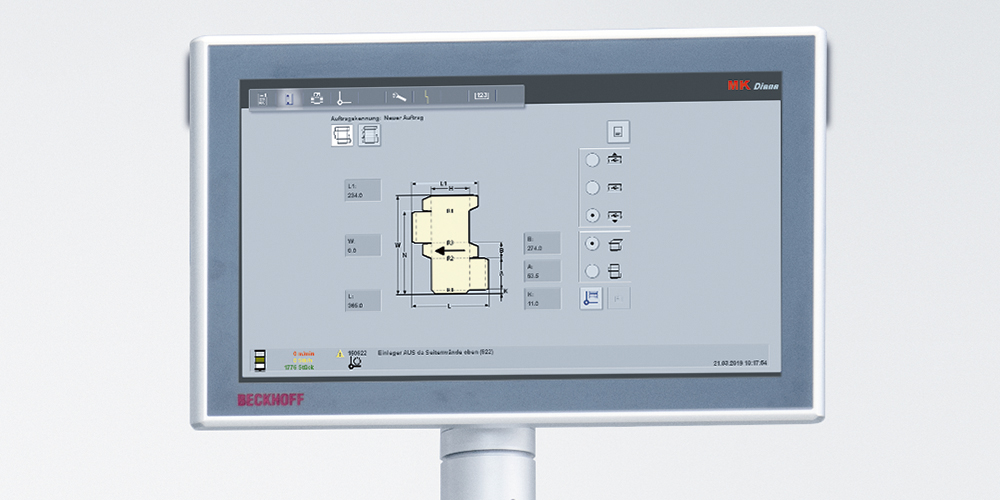

| Material (carton) | 200 - 600 g/m² |

| Material (corrugated board) | Up to F-flute |

| Min. carton width | 75 mm (45 mm optional) |

| Max. carton width | 850 mm |

| Max. speed | 250 m/min (300 m/min optional) |

| Max. machine length | approx. 9.9 m (alignment module optional) |

In this 25 minute webinar, watch the production process of two highly different jobs on the Diana Go 85 folding carton gluing machine: first, the production of a straight-line carton, then, a complete change-over into a lock-bottom box.

Discover the wide range of applications offered by the Diana Go 85.

When they signed the contract to purchase the Diana Go 85, neither Benoit Ayer from Polygravia, Switzerland (2nd to the left on the picture) nor Algirdas Apulskis and Tomas Ketlerius from UAB Druka, Lithuania (in the middle) had ever seen the machine.

"We fully trust the quality of Heidelberg products. That's why we signed the contract for the new Diana Go 85 before we even saw it. The first time we had an opportunity to experience this machine live was at a customer event at Masterwork in Slovakia in March 2019. Our trust has totally paid off".

The Diana Go 85 is manufactured by Masterwork and exclusively distributed and backed up by the professional and renowned, worldwide sales- and service network of Heidelberg.