The new Boardmaster is the most modern, feature-laden flexographic press available - and nothing less than a redefinition of flexo printing. The Boardmaster gives you unparalleled, continuous functionality when changing from one job to the next. Eliminate changeover downtime for good. And more than that, achieve up to an entire extra shift of production per year.

Imagine you could double the productivity of your printing business while reducing costs at the same time. The new Boardmaster does just that. It allows you to change from one job to the next, at full production speed, with minimal waste and zero downtime. Downtime is turned into uptime, maximizing your productivity and return on investment.

Whether food or beverage packaging, lottery tickets or general folding boxes, the Boardmaster can be fitted to your specific needs. The choice of four different web widths, two different types of print decks, hot air, UV or even hybrid drying will give you unmatched flexibility in packaging production.

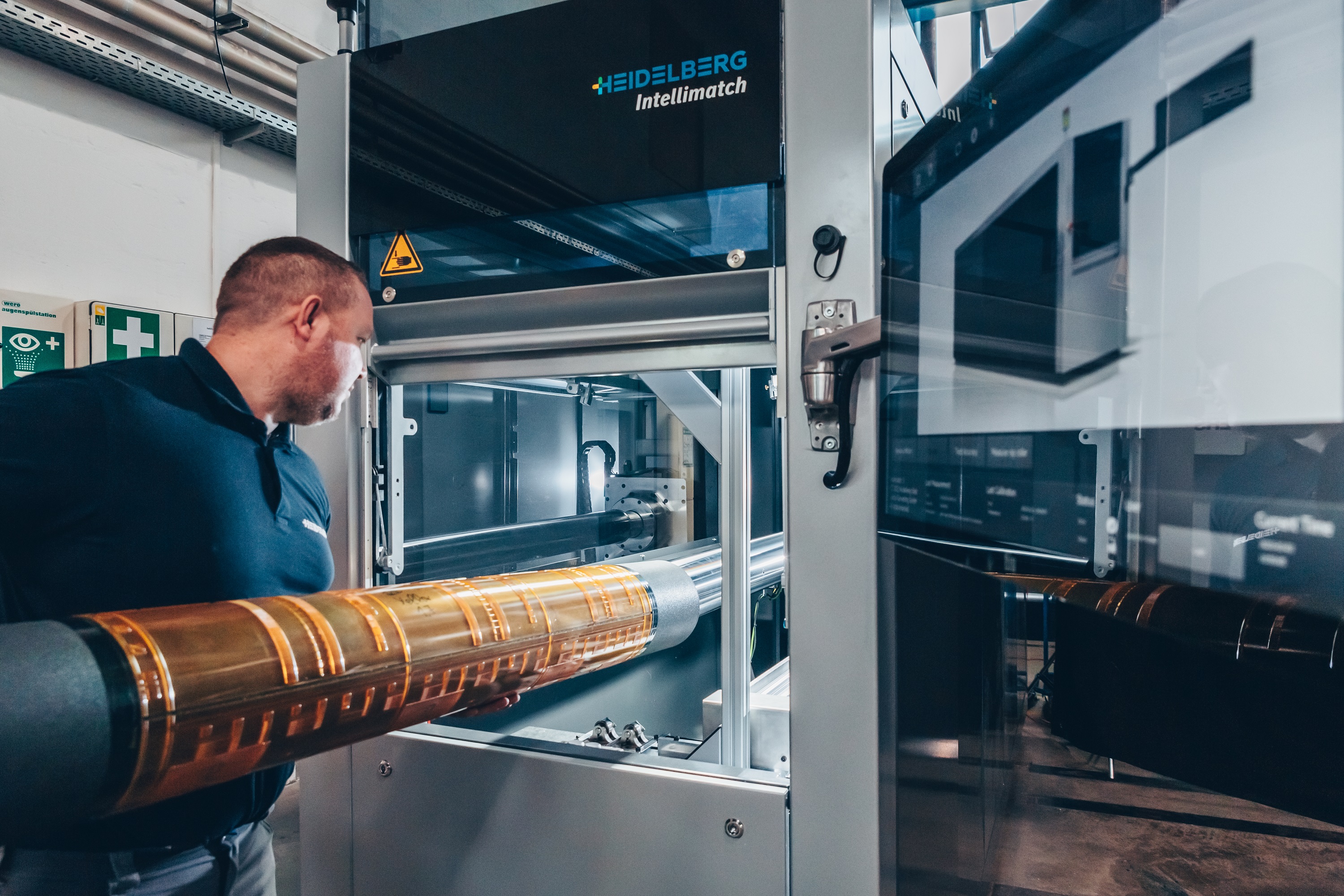

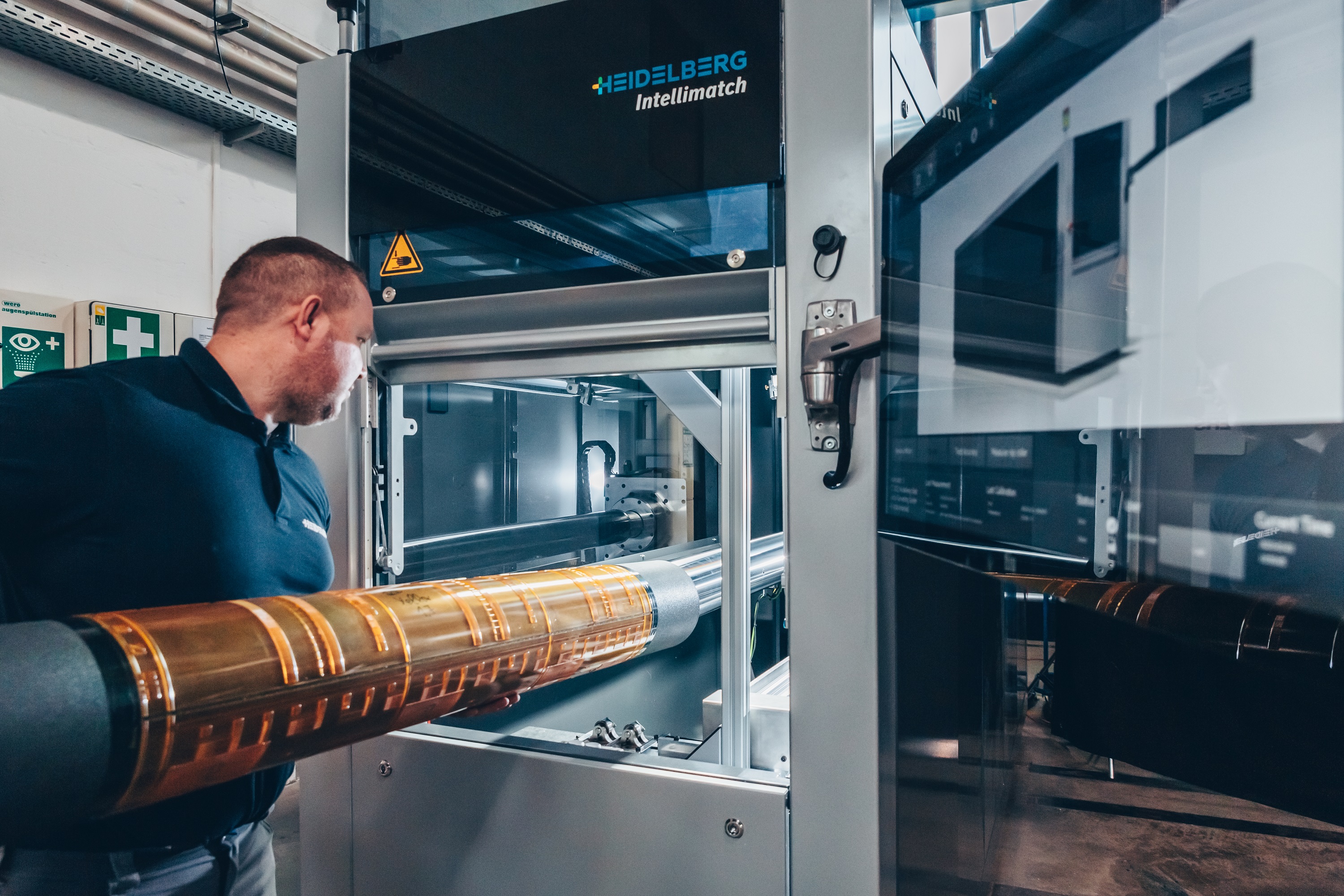

Introducing AI to the world of flexo: with Intellimatch. Adjusting impression is the single biggest time loss when operating a conventional flexo press. By scanning the topography and print image in minute detail with the Intellimatch scanner, the Boardmaster automates the entire process while achieving perfect impression at the same time.

This unique offline printing plate and sleeve scanner provides all press parameters for the Boardmaster. Intellimatch can also detect plate mounting errors, out-of-round print sleeves, and debris before the plate ever gets to the press.