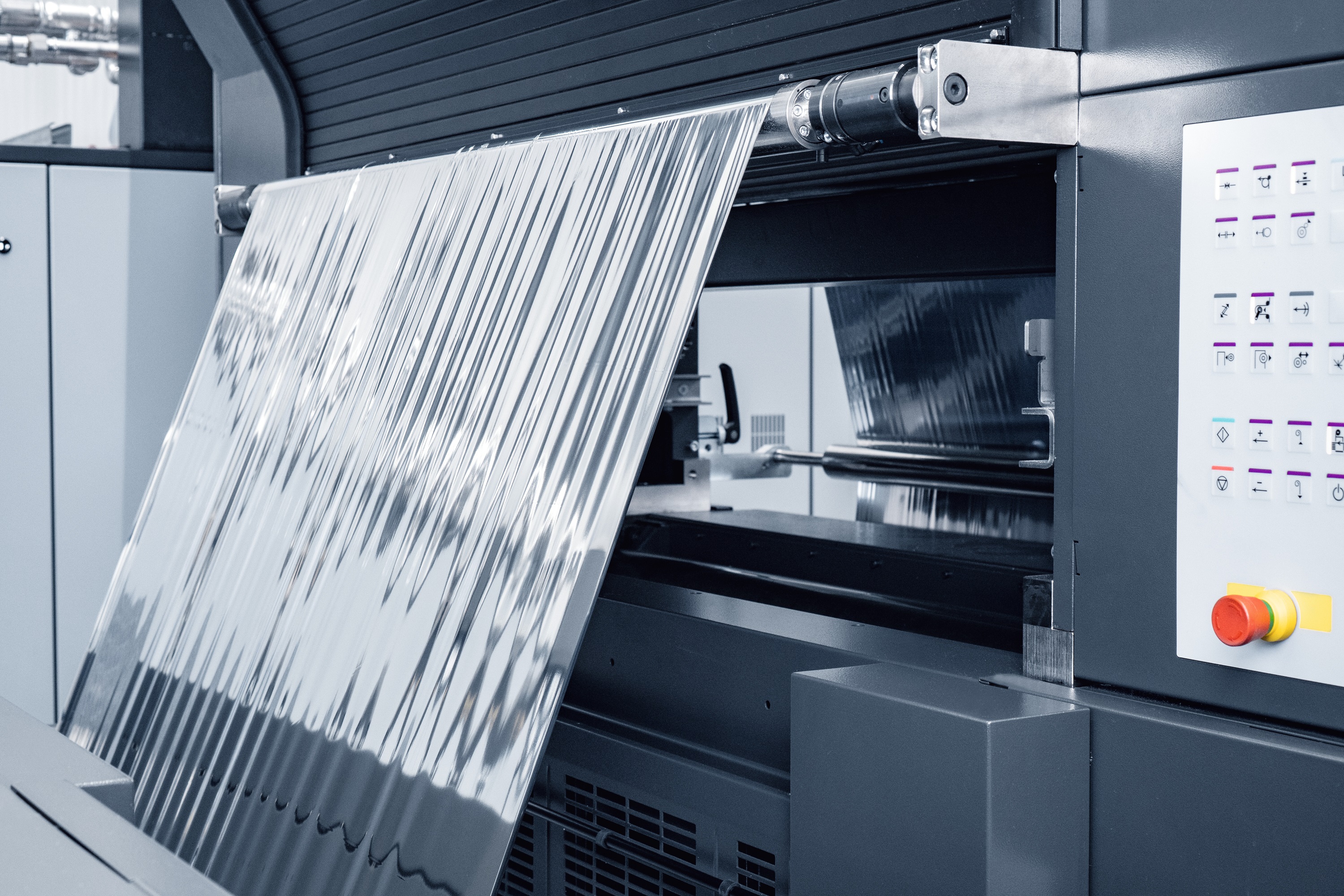

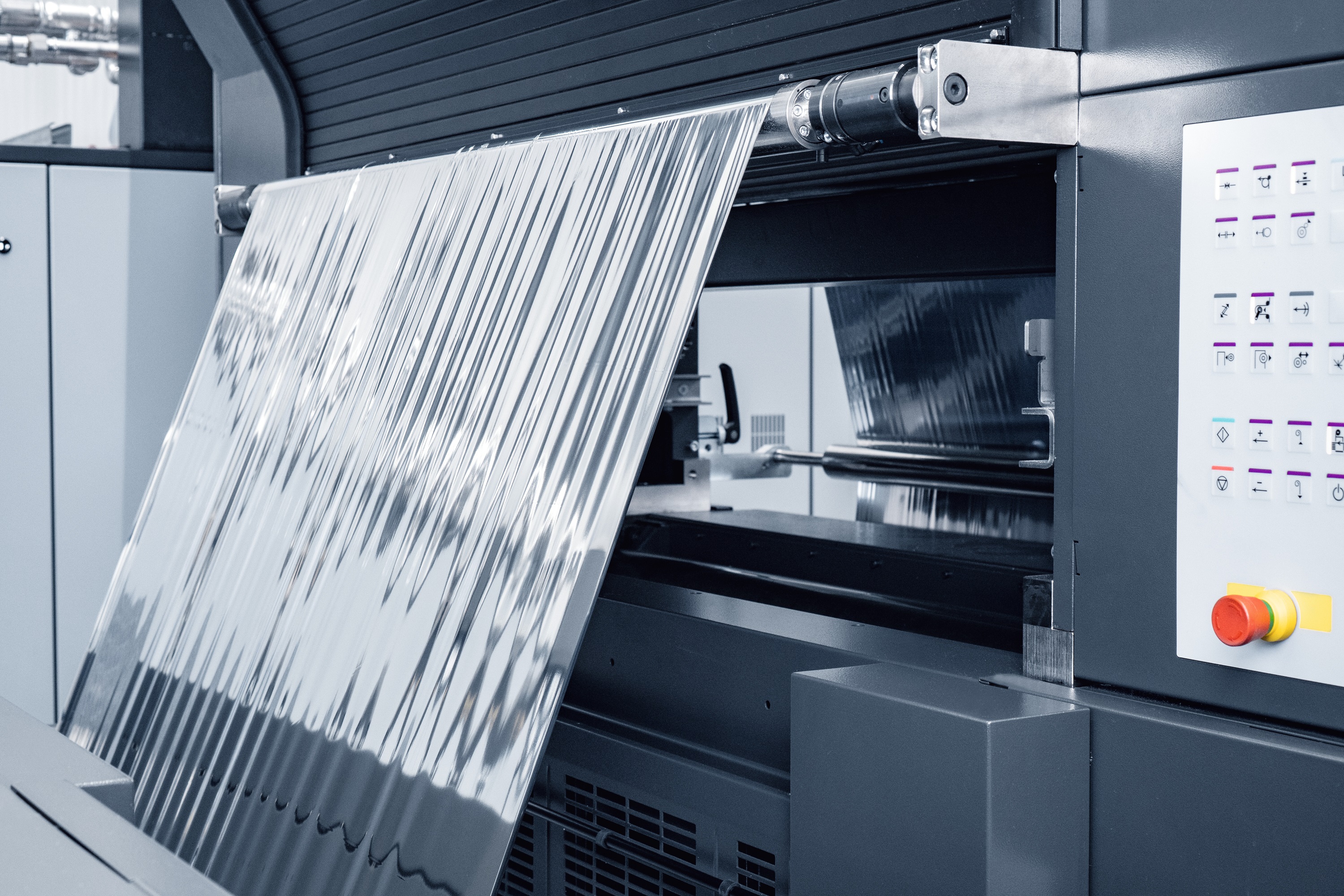

FoilStar, HEIDELBERG’s cold transfer module, supports a whole host of unusual finishing effects for labels, packagings, and high-quality commercial work – giving you access to brilliant metallic effects that will add considerable value to your customers’ print products. Using FoilStar on the Speedmaster XL 75, Speedmaster CX 104 and Speedmaster XL 106 enables a wide range of substrates to be finished in excellent quality.

FoilStar is also available for Speedmaster XL 105, Speedmaster CX 102, Speedmaster CD 102 and Speedmaster CD 74 presses as retrofit.

The FoilStar can be used to create amazing metallic finishes on a wide variety of substrates. The metallic elements are applied and overprinted in a single pass. Short set-up times and fast job changes are a matter of course. The high register accuracy also speaks for the FoilStar.

The printing forms required are cost-effective and make economical production possible.

Thanks to its perfect integration into the central machine control system, it is particularly user-friendly.

If it is not necessary to use the FoilStar, the printing unit on which the FoilStar is mounted can be used for conventional production.

Cold transfer perfected for industrial in-mold (IML) label production in UV or LED UV process.

FoilStar Cure makes it possible to produce metallic finishing effects with cold transfer on in-mold label material, primarily with LED UV drying. This technology achieves a higher drying capacity, while at the same time the heat input to the substrate and energy consumption are reduced.

The modified web guidance with a long wrap angle on the impression cylinder serves to cure the transferred metallic pigment as one with the UV adhesive and substrate by means of an LED UV interdeck dryer. This produces better adhesion of the metallic pigments, and thus also high process stability, and a much higher metallic gloss.

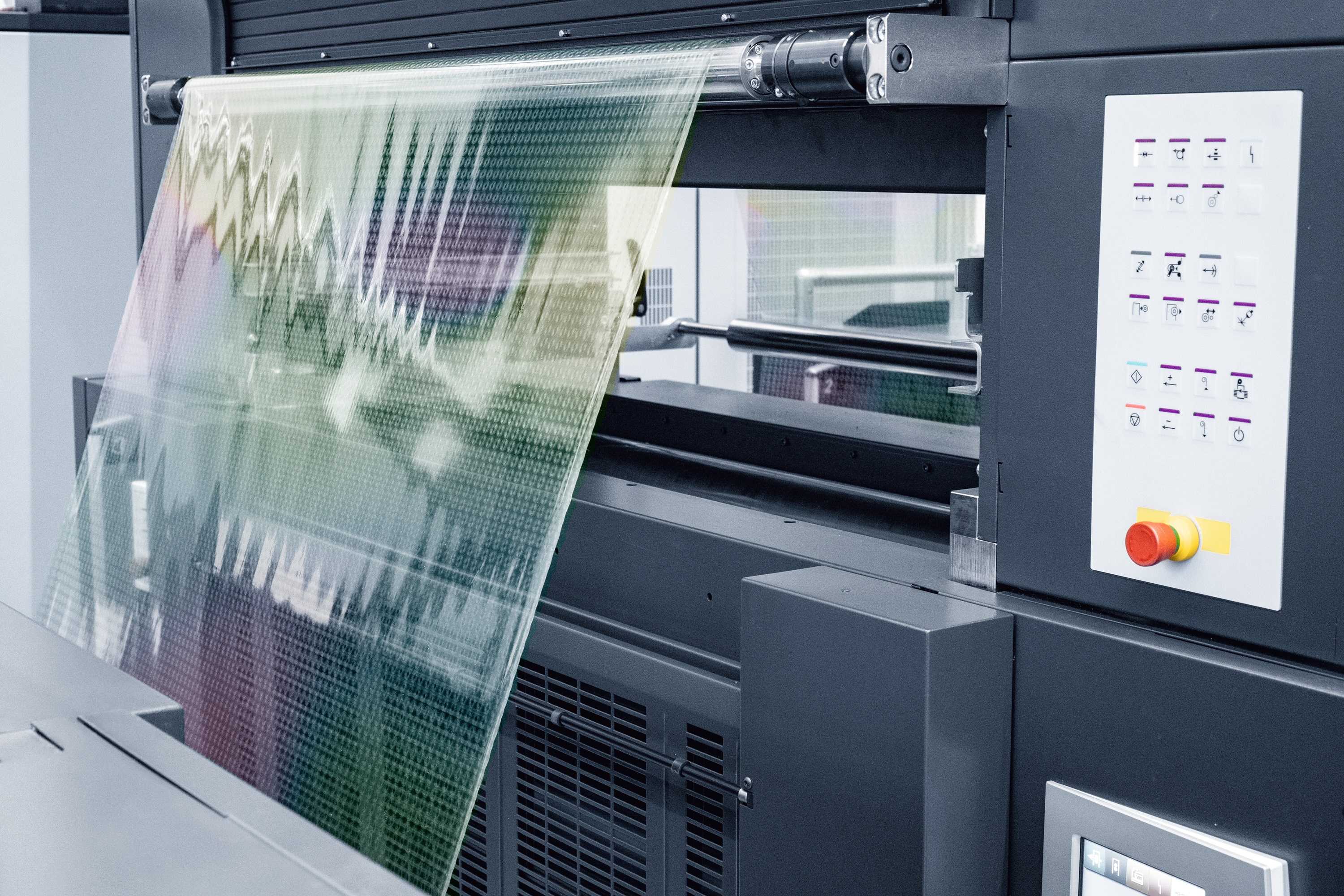

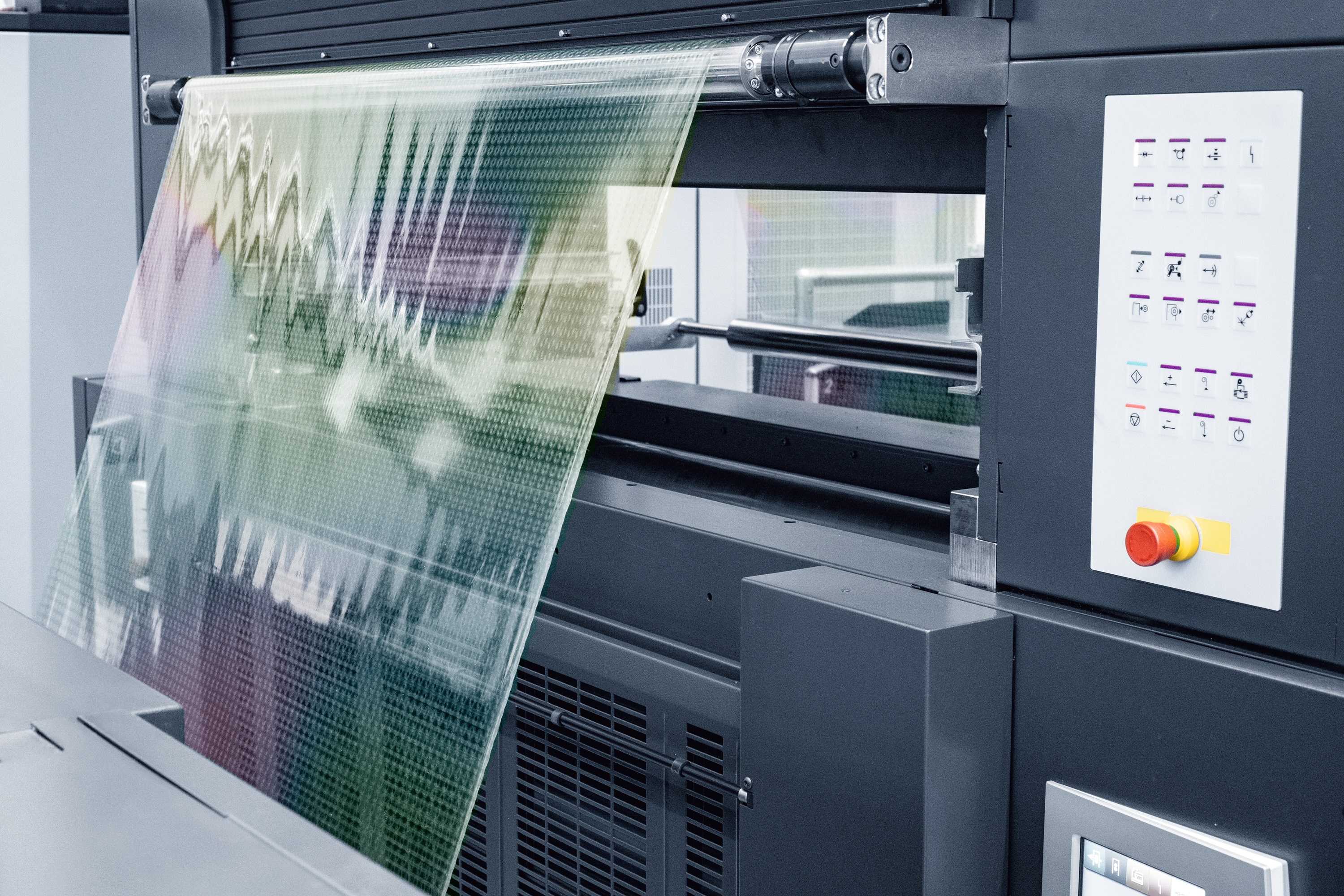

Cast & Cure technology is a costeffective inline process in which highgloss and hologram effects can be created by using UV coatings and special holographic foils.

The difference to conventional cold transfer: with this technology, no metallic pigments are transferred to the substrate. With Cast & Cure, a holographic micro-embossing is created on the surface of a previously UV-coated substrate with the help of the foil. Gloss films for high-gloss effects and matt films for ultra-matt effects and holograms can be realized efficiently with the FoilStar Cast & Cure.

The particular advantage here is that the foil can be used several times – this saves resources and protects the environment in the long term. The FoilStar Cast & Cure can be positioned on printing units before and after the coating unit.

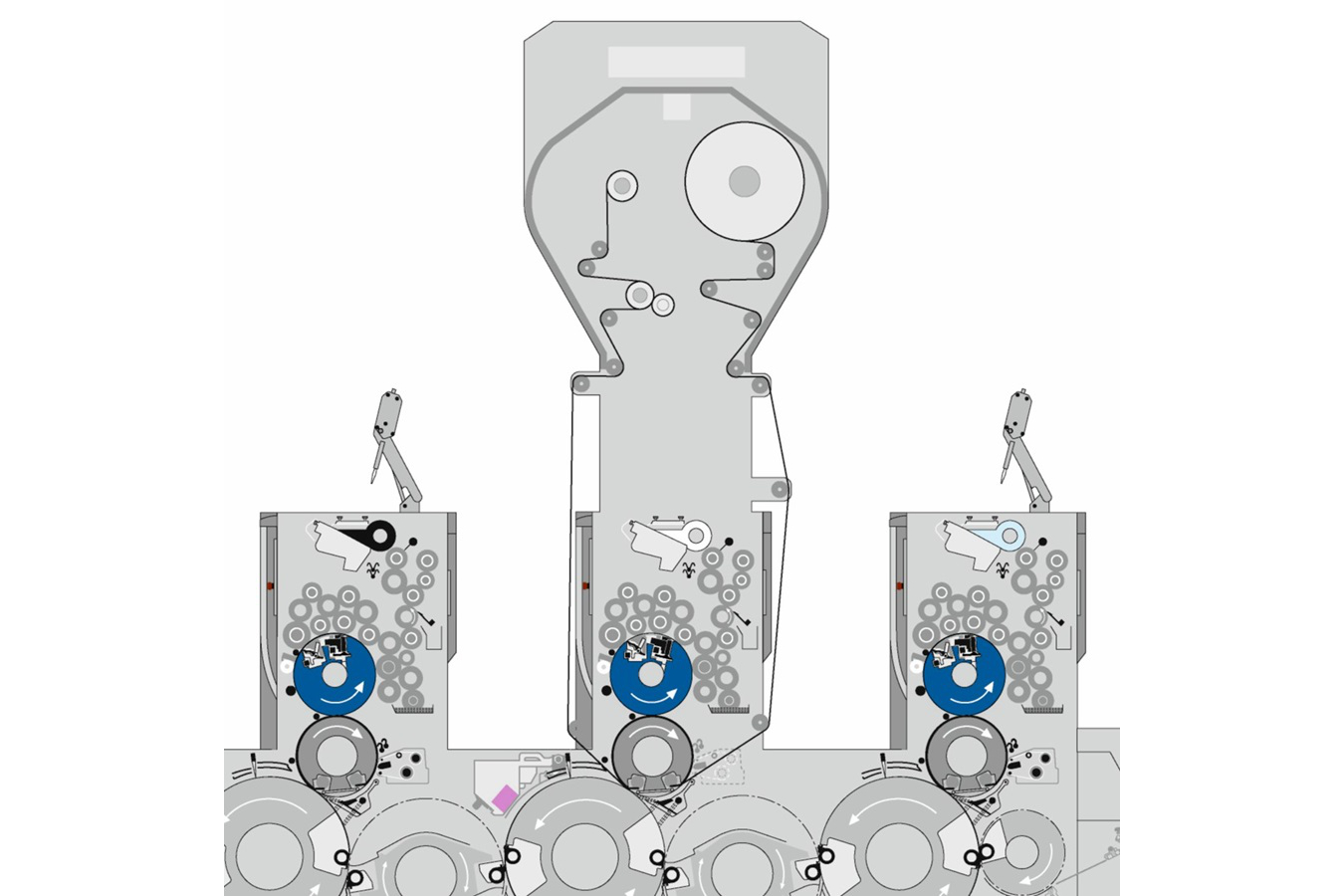

Without indexing in single-reel operation

In the basic version, the FoilStar produces in single-reel operation and without indexing function at production speeds of up to 21,000 sheets/hour. The single-reel operation scores with low maintenance costs thanks to the new pneumatic shaft.

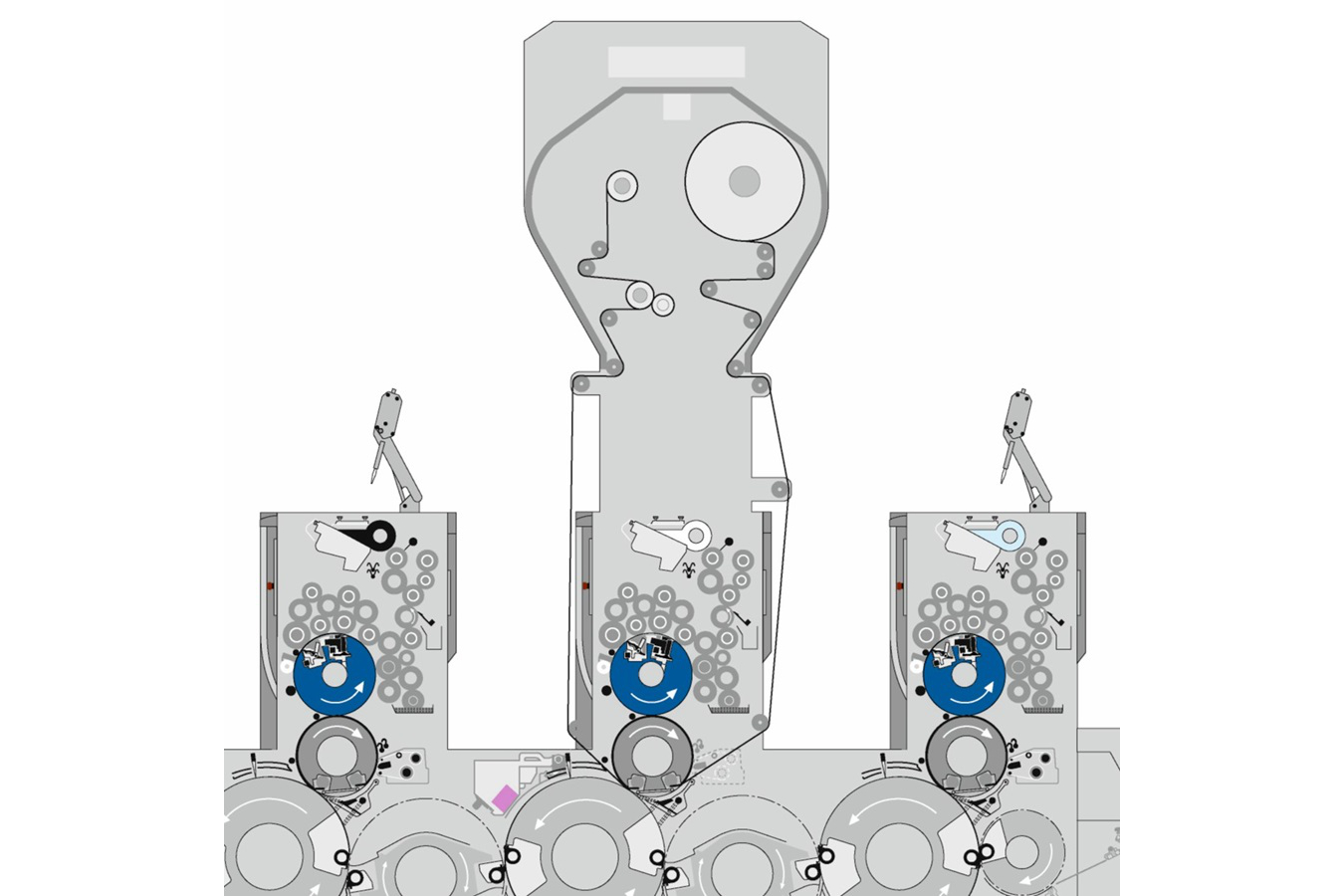

Without indexing in multi-reel operation

The FoilStar can also be equipped for multi-reel operation. Up to six narrow reels can be used and the positioning can be individually selected. Even without indexing, production is even more economical, and foil waste can be significantly reduced. More flexibility thanks to the new robust friction shaft, single-reel and multi-reel operation are possible at any time.

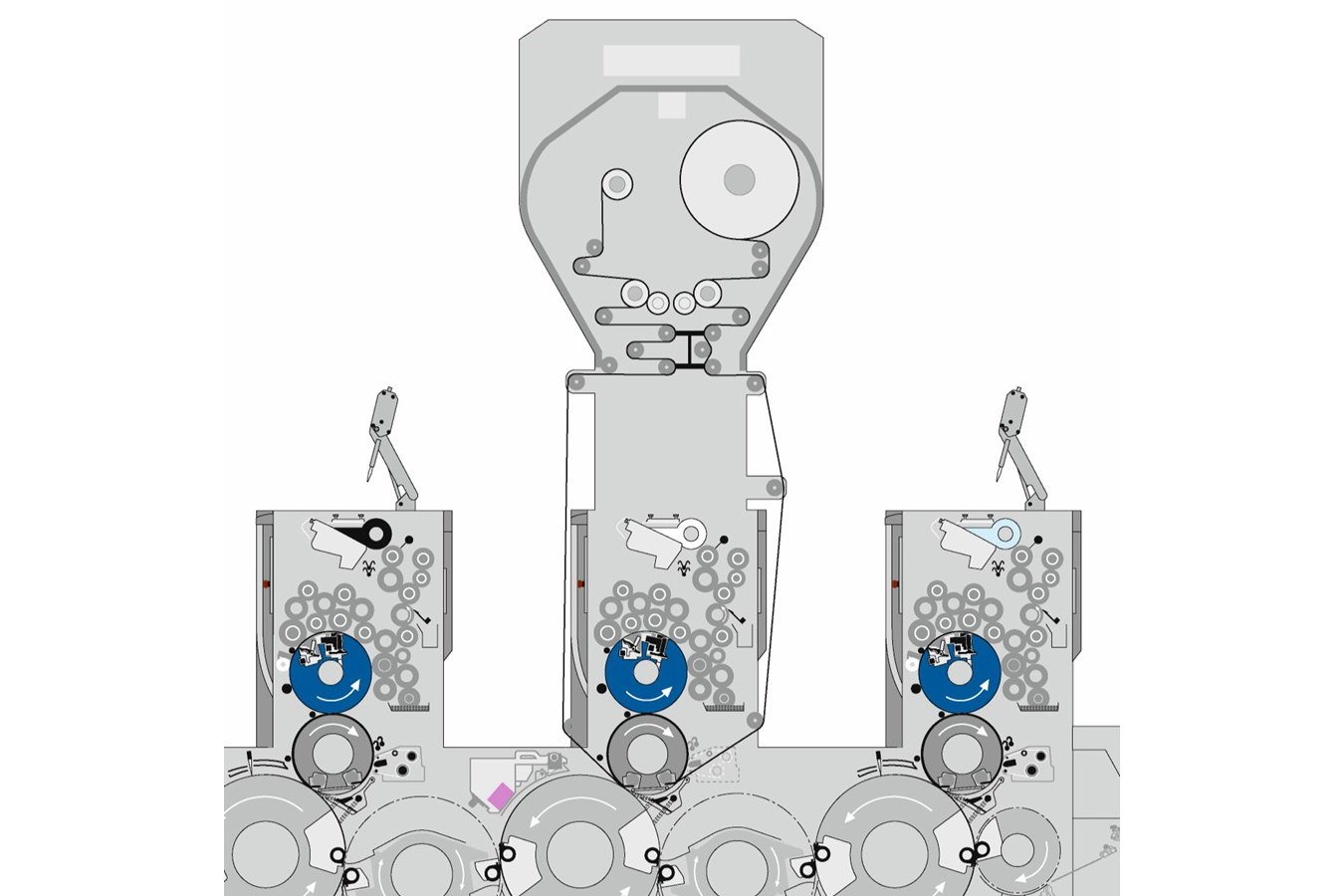

With indexing in single-reel operation

If the FoilStar is equipped with the new indexing function, you always save 30 percent to over 80 percent foil material, depending on the indexing length. Benefit from the modern indexing unit, which enables higher, provides better running properties of the web thanks to increased robustness and makes cleaning easier than ever for the operator thanks to improved accessibility.

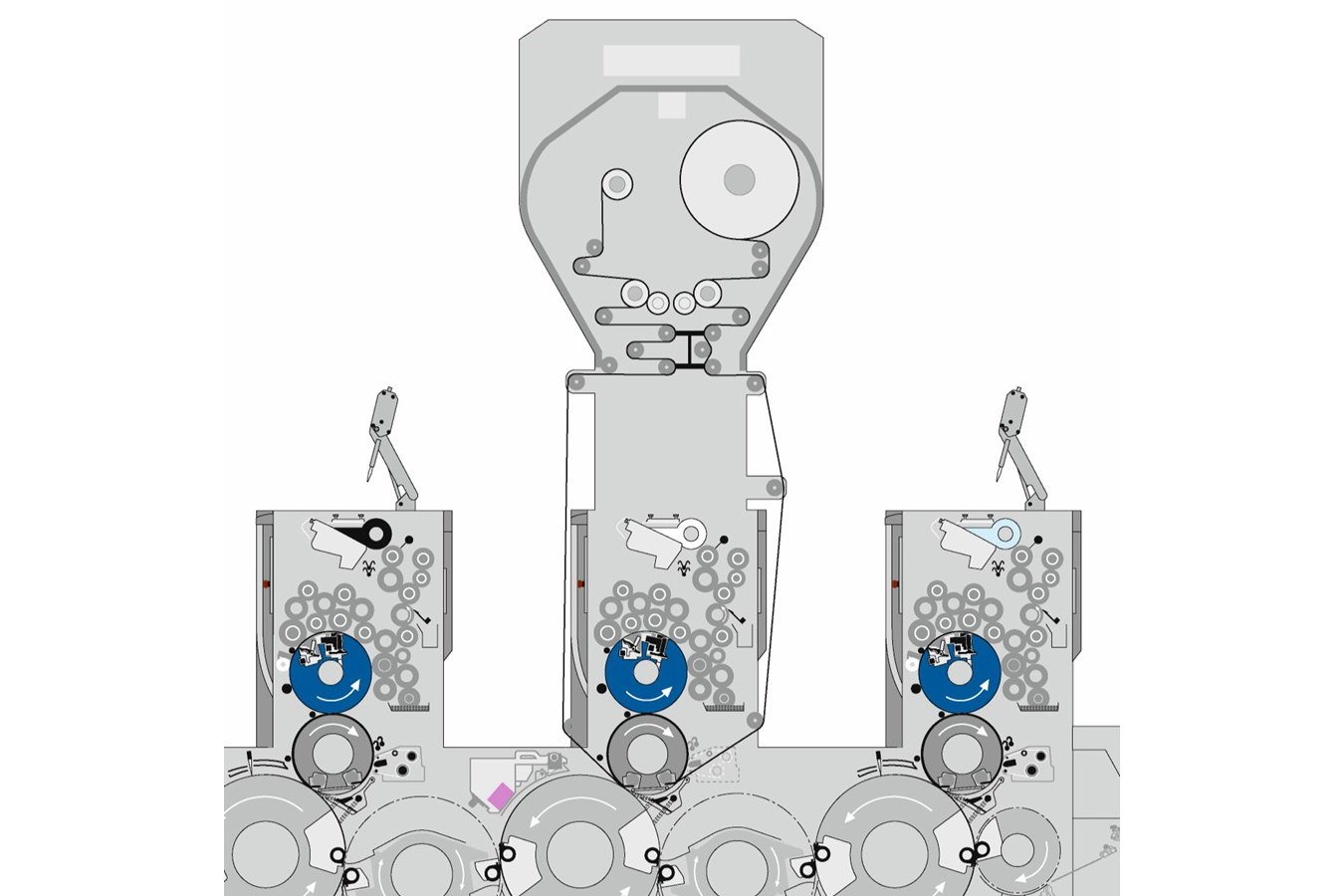

With indexing in multi-reel operation

The most economical and ecological equipment combination. Up to six reels can be used – this reduces foil waste the most. Over 80 percent can be achieved. Depending on the indexing length, the production speed varies between 15,000 and 20,000 sheets/hour.

Packaging finished with cold transfer is recyclable, as the aluminum pigments transferred to the substrate can be removed during the de-inking process.

In addition, the FoilStar allows the indexing lengths to be individually adapted to the print layout. The aluminum pigments are only transferred to the defined areas of the packaging. Depending on the layout, this saves over 80 percent material, protects the environment and reduces material costs.

The trend in the market is towards ever thinner cold foils. The FoilStar can process cold foils with a material thickness of just 6 μm. In conjunction with the indexing function, only as much foil as is actually needed is fed into the recycling loop. This means that production is economical and resource-saving.