The Speedmaster Operating System with intuitive touch control turns the convenient control of the Speedmaster into an experience. Settings can be called up with a click, and the scalable operation can be flexibly adjusted in accordance with the requirement profile. Intuitive operator guidance, innovative gesture control, and integrated help functions eliminate lengthy searches. The Speedmaster Operating System delivers fast, simple and navigated use of all your machine’s functionalities.

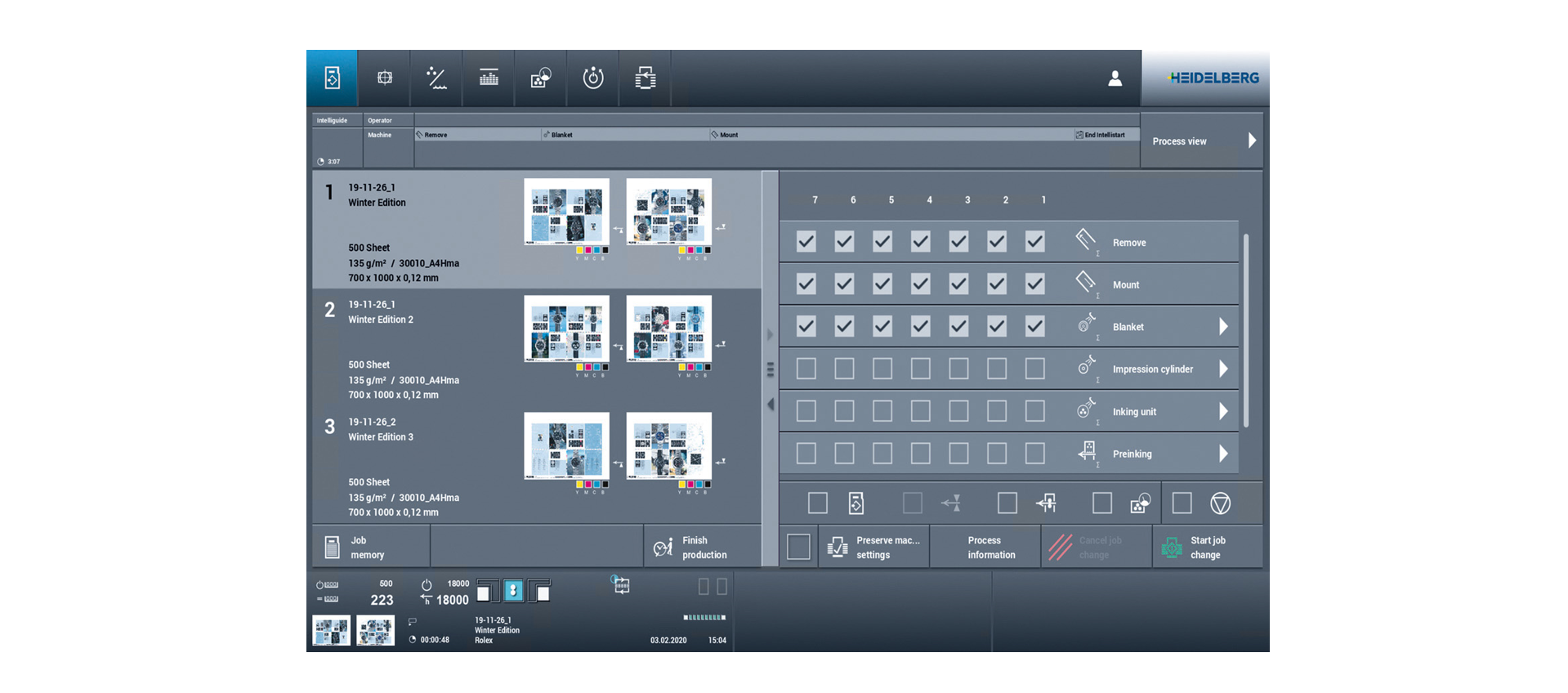

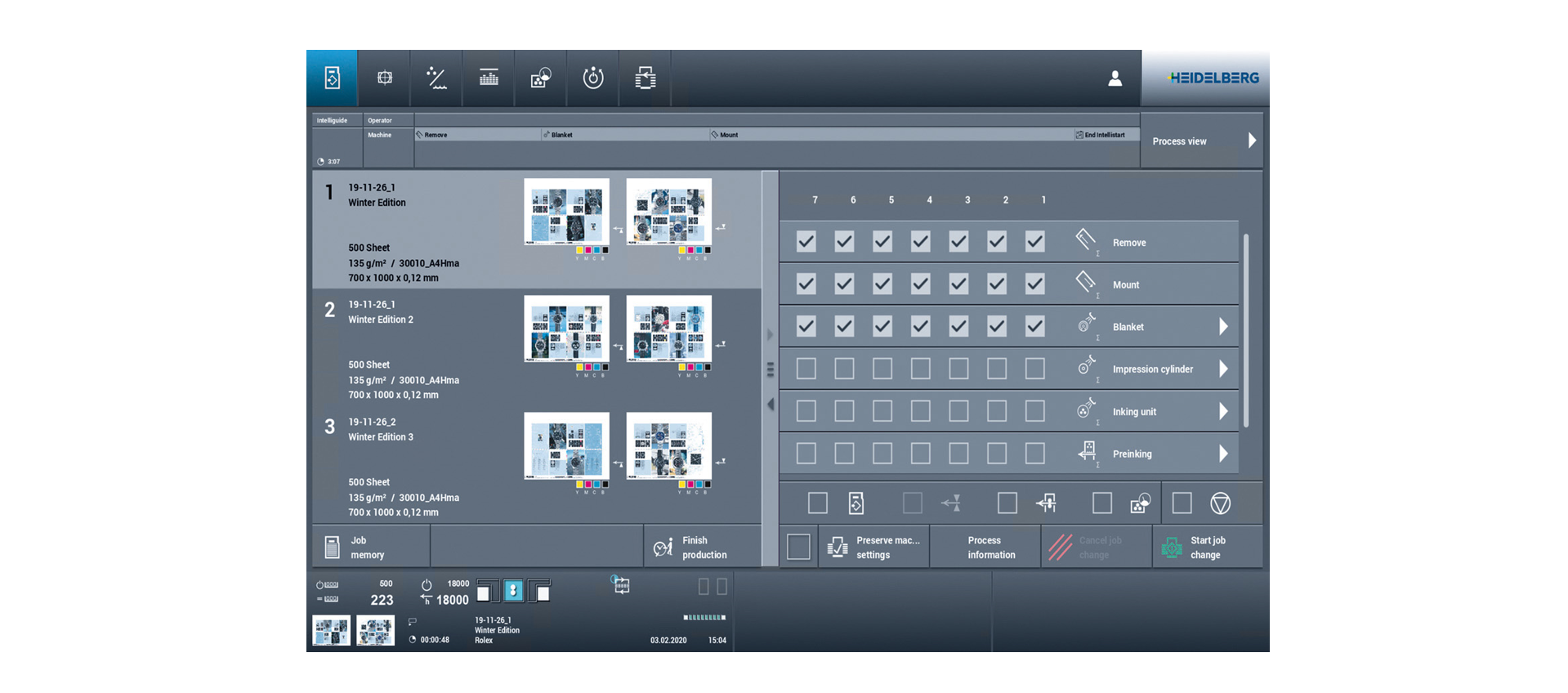

Navigated printing with Push to Stop is possible on all Speedmaster machines. Intellistart 3 defines all the steps required for the job change without any operator intervention and provides maximum transparency across all active and queued processes. Intelliguide simulates the time-optimized sequence live and, if necessary, also includes the steps to be executed manually.

The Wallscreen XL completes the one-of-a-kind operator navigation for the highest performance demands. Intellirun, the dynamic production view, shows the operator the right view at the right time, fully automatically, and provides intelligent information on the current production status. Intellirun thus not only supports you during the automated job change, but also throughout production. All production steps are supported by an up-to-date overall view. The feeder display also shows important job information for optimal integration of the helper.

The Intelliline LED-based navigation extends this logic to the machine. The resulting expansion of the Intelliguide, Intellistart 3, and Intellirun process displays provides a color visualization of the unit status on all printing, coating, and drying units on the operator and drive sides. You can keep an eye on everything at all times and are prompted when intervention is required.

Prinect Press Center 3 and Prinect Press Center XL 3/4 link the printing press to your print shop’s Prinect workflow. Job data can be transferred and also made available in an automatically defined sequence. Production data is returned fully automatically. This enables you to benefit from excellent data management, one-of-a-kind presettings, up-to-date production data, and informative reports.

Our entire range of Prinect color measuring systems offers you optimum, reproducible color stability and minimal waste. As the most cost-efficient system in its class, Prinect Easy Control offers the ideal technology for spectral measurement. The powerful Prinect Axis Control ensures high quality. The inline color measurement system Prinect Inpress Control 3 stands for high productivity. All color measurement systems are perfectly integrated into the workflow. The color library provides the reference values for color control with each job and also serves as the basis for the color reports.