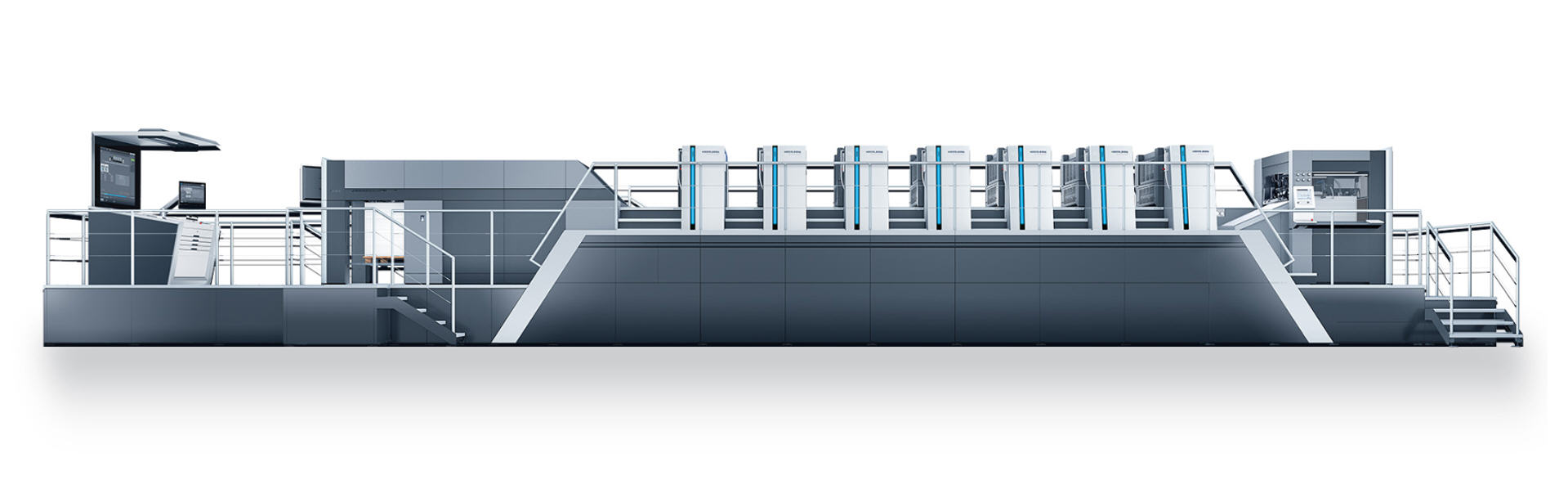

But its constantly high quality with steady production speeds of 18,000 sheets per hour in straight printing or perfecting mode is also impressive in longer runs.

Parallel makeready processes increase productivity in packaging, commercial, and label printing. The intelligent interaction of the automation components enables cost-effective production of all printing products.

The Speedmaster XL 106 is the most intelligent Speedmaster yet with innovative solutions for

Find your optimal configuration too.

Your HEIDELBERG sales representative will be happy to advise you.

In-mold labeling (IML) with the Speedmaster XL 106 at Korsini, Turkey

When Korsini enters the in-mold labeling (IML) segment around 22 years ago, it is still a niche market. Today, the Turkish print shop exports in-mold labels to more than 60 countries and is experiencing rapid growth like almost no other IML manufacturer. The company’s close cooperation with HEIDELBERG is a cornerstone of this success.

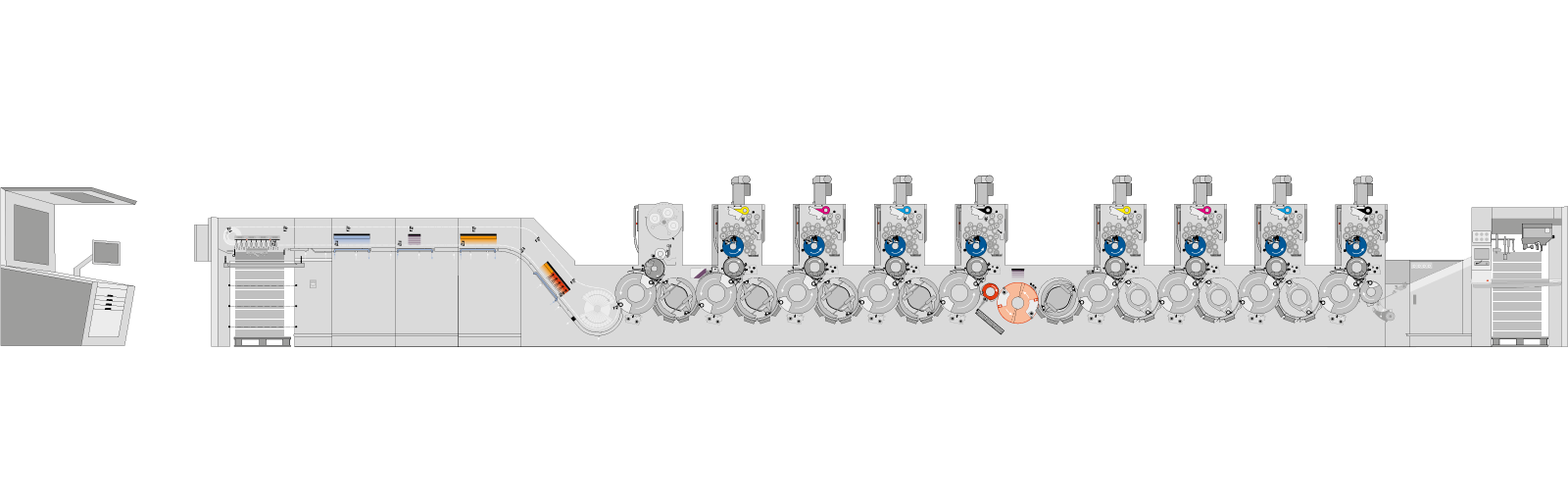

The printing unit

3

Prinect Inpress Control 3

5

The inking unit and dampening unit

4

The dryer systems

9

The Preset Plus delivery

10

The washup devices

7

The coating unit

8

The machine control station – one-of-a-kind navigation and automation

11

Plate logistics

1

The Preset Plus feeder

2

Sheet travel and perfecting device

6

The printing unit

3

Prinect Inpress Control 3

5

The inking unit and dampening unit

4

The dryer systems

9

The Preset Plus delivery

10

The washup devices

7

The coating unit

8

The machine control station – one-of-a-kind navigation and automation

11

Plate logistics

1

The Preset Plus feeder

2

Sheet travel and perfecting device

6

Every time you operate a component you are experiencing the Peak Performance concept. From the seamlessly ergonomic design, to the pioneering touchscreen control panels, the simple handling of the washup devices to the unique preset functionality, the SpeedmasterXL106 delivers an unparalleled user experience.

Prinect Production digitizes your print shop. It automates your production as well as your color and quality management and provides important data for analyses and reporting. With Prinect Production, the smart integration of your digital printing press ensures you are also perfectly equipped for short runs and variable data printing.