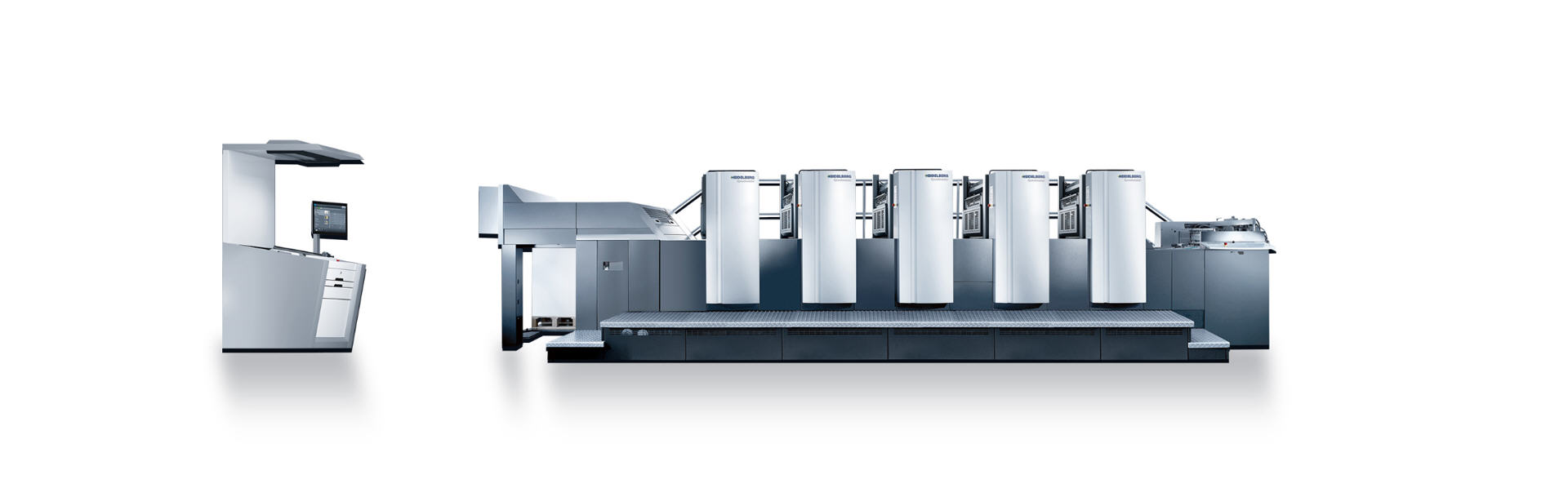

With short makeready times, printing speeds of up to 15,000 sheets per hour, and optionally with high-pile delivery, perfecting press, or UV technology, the Speedmaster SX 74 is designed for high productivity at all times.

It makes it easy for you to stand out from the competition with reliable quality. Thanks to the Prinect Press Center 3 control station, it is easy to operate and can be integrated into the Prinect workflow. Its energy efficiency and resource-efficient use of materials have a positive impact in terms of both the environment and costs.

Another plus: each Speedmaster SX 74 is backed up by the comprehensive service offering from HEIDELBERG. This enables you to get the most from your printing press at all times thanks to maintenance, remote functions, perfectly coordinated consumables, and an international service and spare parts network.

thanks to fast plate changes with AutoPlate Pro

thanks to the innovative, navigated operator guidance system Intellistart 3

Select and release for printing with just 2 clicks

Less paper waste, and easy reproducibility thanks to colorimetric control with Prinect Easy Control

The Speedmaster SX 74 is ideally suited to meet the requirements of packaging and commercial printers.

To find your optimal configuration, please contact your

local HEIDELBERG sales representative or distributor.

Prinect Production digitizes your print shop. It automates your production as well as your color and quality management and provides important data for analyses and reporting. With Prinect Production, the smart integration of your digital printing press ensures you are also perfectly equipped for short runs and variable data printing.